Network feedforward control method of cold rolling mill thickness control system

A technology of thickness control and feed-forward control, which is applied in rolling mill control devices, control/regulation systems, metal rolling, etc., can solve problems such as fault diagnosis and recovery difficulties, fault diagnosis difficulties, and reduced accuracy of measurement data, etc., to achieve enhanced fault Diagnosis and recovery capabilities, improved fault diagnosis and recovery capabilities, and improved anti-jamming capabilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

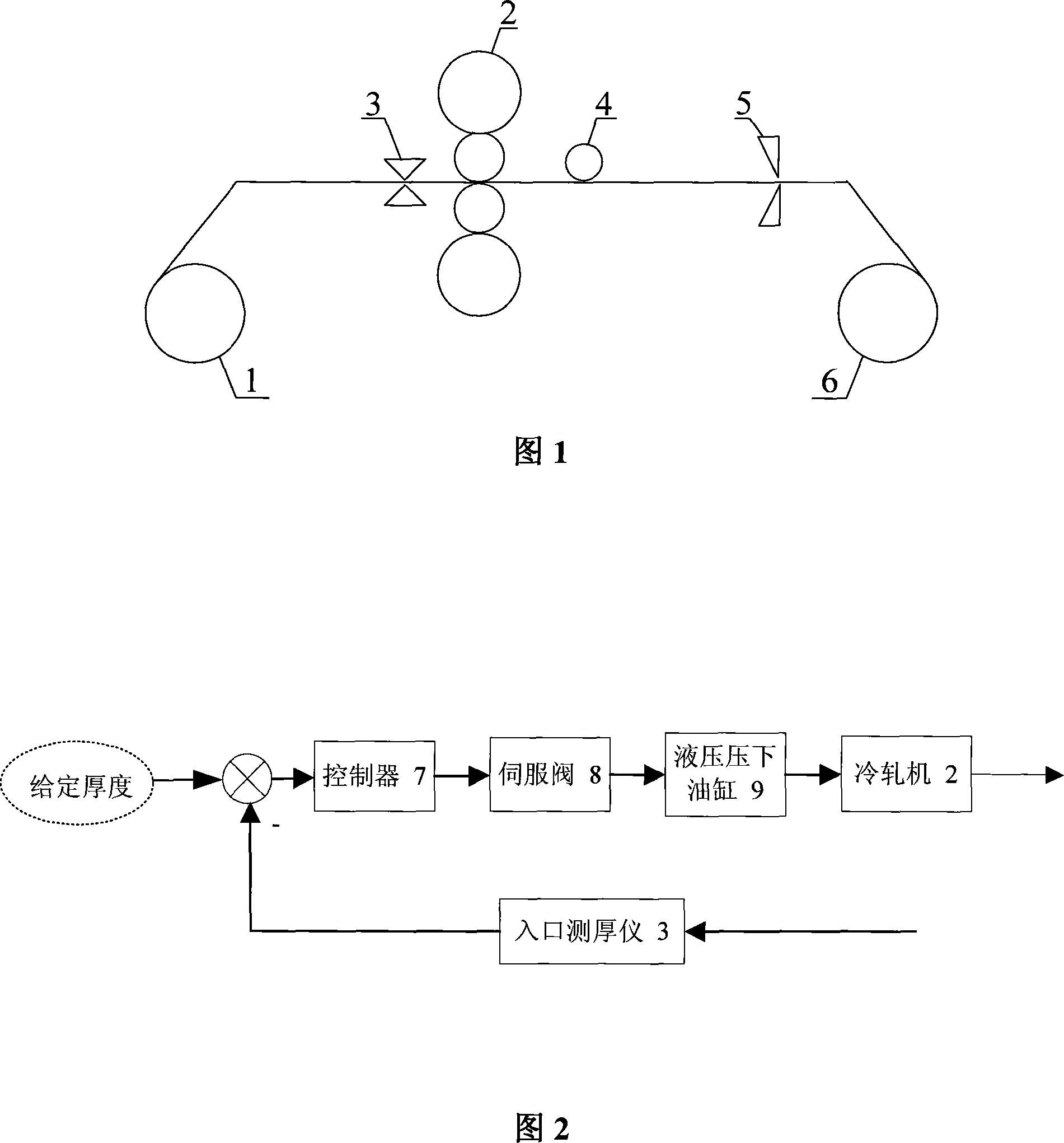

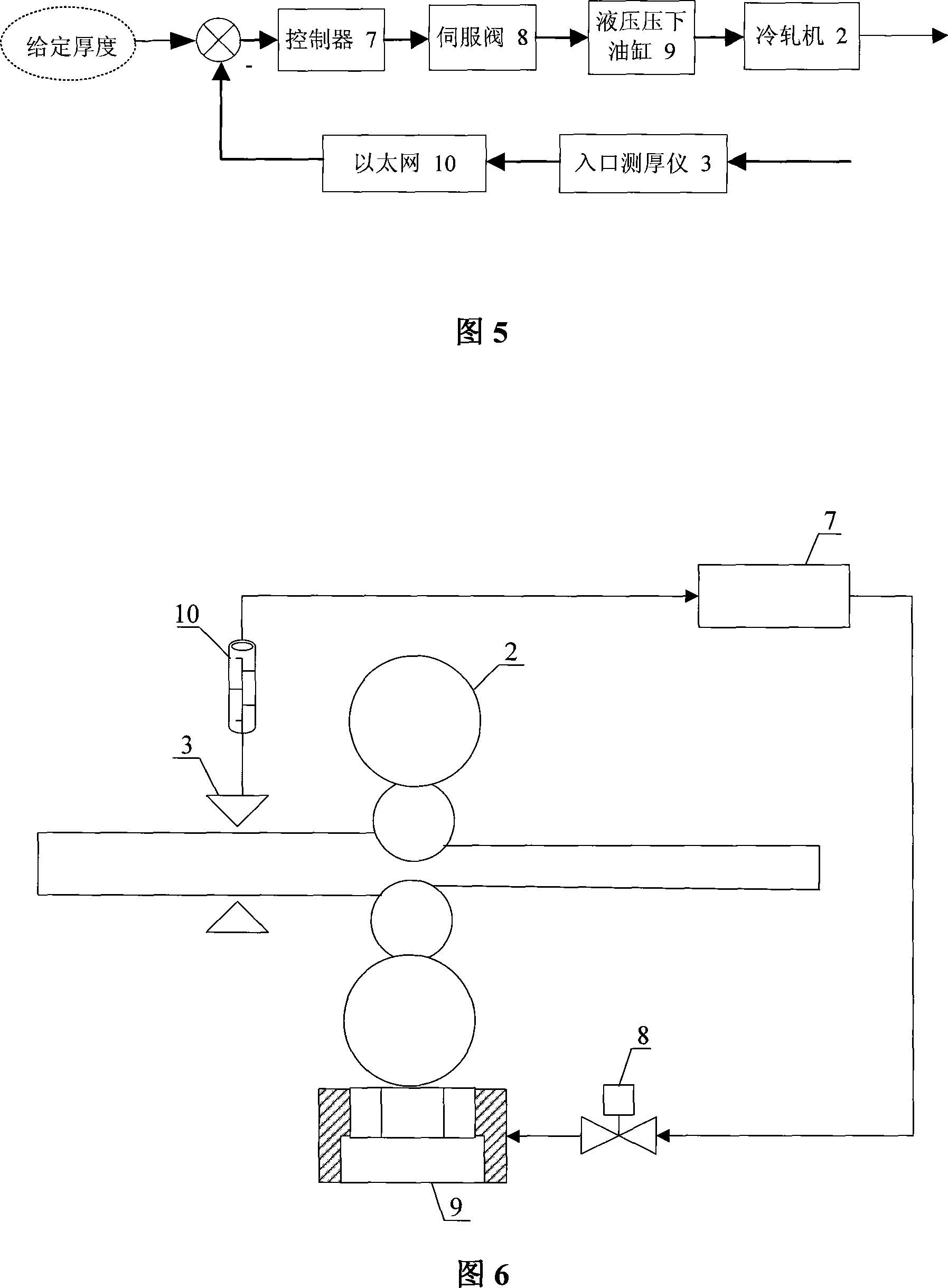

[0037] The cold rolling mill composition of metal processing equipment is shown in Figure 1, including uncoiler 1, cold rolling mill 2, entrance thickness gauge 3, flat roll 4, scissors 5 and coiler 6. The network feed-forward control method of the thickness control system of the cold rolling mill of the present invention uses an inlet thickness gauge, an Ethernet, a controller and a hydraulic pressing device as the thickness control equipment. The cold rolling mill thickness control system of the present invention is as shown in Figure 5, and the cold rolling mill thickness control system of the present invention is composed as shown in Figure 6, including entrance thickness gauge 3, Ethernet 10, controller 7, servo valve 8 and Hydraulically press the oil cylinder 9, the controller 7 adopts a programmable logic controller PLC or an industrial control computer IPC, the connecting cable of the Ethernet communication interface adopts a shielded twisted pair or optical cable, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com