Method for reclaiming sulfuric ammonium and ferric oxide from sulfuric acid pickling waste fluid

A sulfuric acid pickling, ammonium sulfate technology, applied in iron oxide, chemical instruments and methods, iron oxide/iron hydroxide, etc., can solve the problem of poor quality, difficult separation of iron oxide precipitation and ammonium sulfate solution, low purity of ammonium sulfate, etc. problems, to achieve the effect of good product quality and meet the requirements of agricultural fertilizer requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

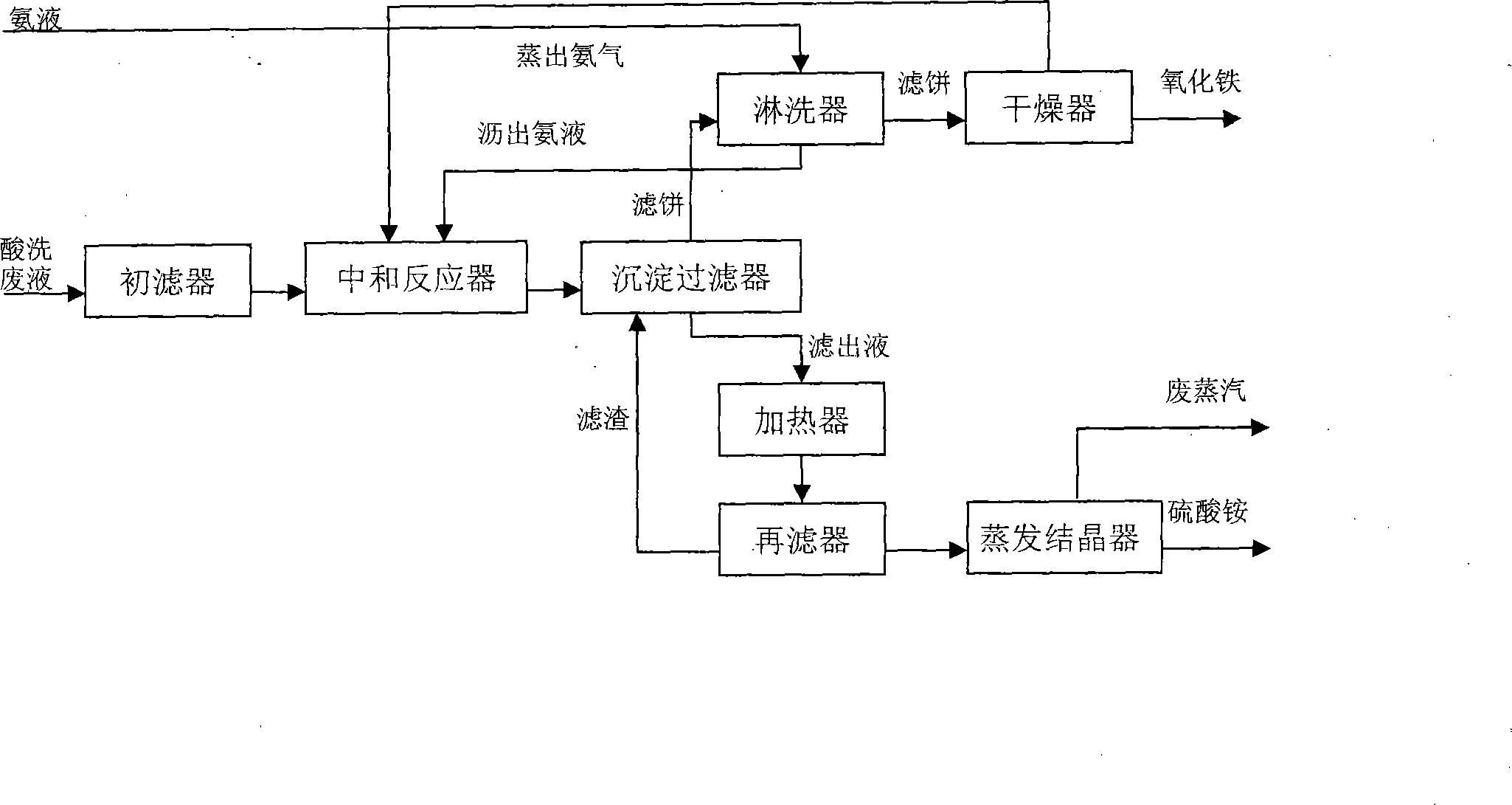

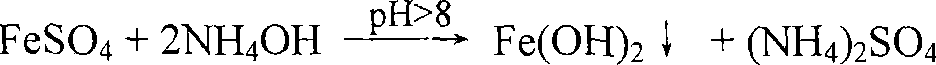

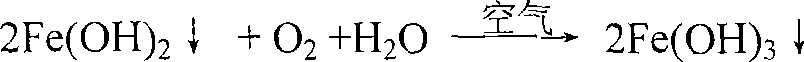

Method used

Image

Examples

Embodiment 1

[0018] Embodiment 1: the pickling waste liquid containing ferrous sulfate and waste sulfuric acid weight percentage 25%, after removing solid particle impurity by primary filter, waste liquid enters neutralization reactor; Add polyacrylamide solution before neutralization reaction is carried out, Make the concentration of polyacrylamide in the waste liquid be 100ppm (that is, 0.01% by weight), and then add ammonia water with 25% by weight of ammonia under stirring for neutralization. When the pH value of the neutralization reaction reaches 8.5, add a sedimentation filter to carry out Separated by filtration. The filtrate was heated to 90° C., kept at a constant temperature for 10 minutes, and then filtered again to remove impurities; the secondary filtrate was evaporated and crystallized, and the obtained ammonium sulfate had a white color, and the iron element weight percentage of the crystallized product was 0.00047%. Product quality is good.

[0019] The volume of the filt...

Embodiment 2

[0020] Embodiment 2: the acid pickling waste liquid containing ferrous sulfate and waste sulfuric acid weight percentage 10%, after removing solid particle impurity by primary filter, waste liquid enters neutralization reactor; Add polyacrylamide solution before neutralization reaction carries out, Make the concentration of polyacrylamide in the waste liquid be 500ppm (that is, 0.05% by weight), and then add ammonia water with 25% by weight of ammonia under stirring for neutralization. When the pH value of the neutralization reaction reaches 11.5, add a sedimentation filter to carry out Separated by filtration. The filtrate was heated to 60° C., kept at a constant temperature for 60 minutes, and then filtered again to remove impurities; the secondary filtrate was evaporated and crystallized, and the obtained ammonium sulfate had a white color, and the iron element weight percentage of the crystallized product was 0.0016%. Product quality is good. The volume of the filter cake...

Embodiment 3

[0021] Embodiment 3: the pickling waste liquid that contains ferrous sulfate and waste sulfuric acid weight percent 30%, after removing solid particle impurity by primary filter, waste liquid enters neutralization reactor; Add sodium polyacrylate solution before neutralization reaction is carried out, Make the concentration of sodium polyacrylate in the waste liquid be 50ppm (that is, the weight percentage is 0.005%), then add ammonia water with 25% by weight of ammonia under stirring for neutralization, and when the pH value of the neutralization reaction reaches 8, add a sedimentation filter to carry out Separated by filtration. Under airtight conditions, heat the filtrate to 105°C, keep the temperature constant for 5 minutes, and then filter again to remove impurities; the secondary filtrate is evaporated and crystallized, and the ammonium sulfate obtained is white in color, and the weight percentage of iron in the crystallized product is 0.0009 %. Product quality is good....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com