High, depth and width three-dimensional uprightness interconnect and realization method of three-dimensional integrate circuit

An integrated circuit and vertical interconnection technology, applied in the direction of circuits, electrical components, electric solid devices, etc., can solve the problems of difficulty in ensuring the insulation effect of interconnecting lines, limiting interconnection line density, and difficulty in the growth of insulating layers. High-density 3D vertical interconnects, avoiding voids and gaps, and eliminating dependencies

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

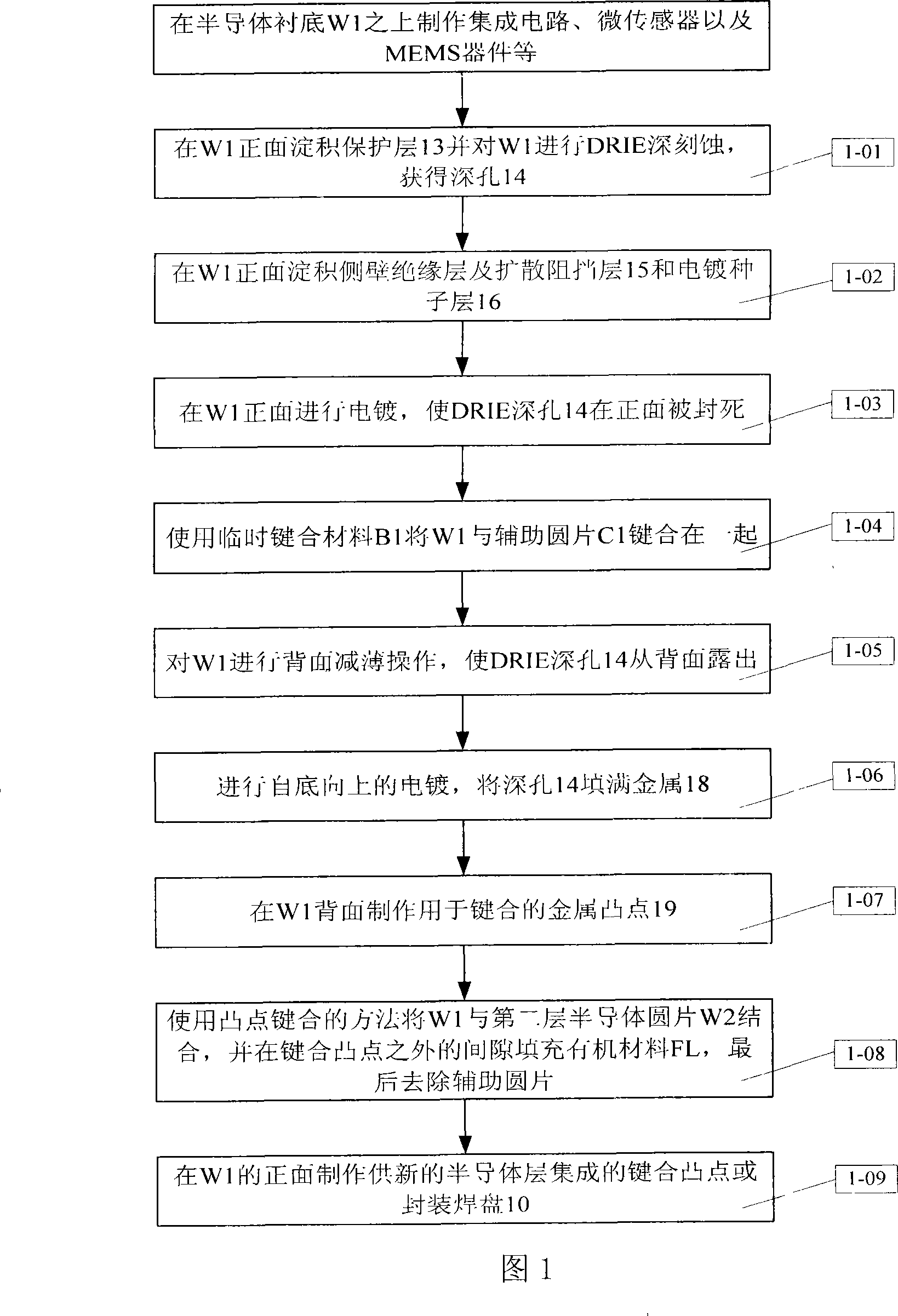

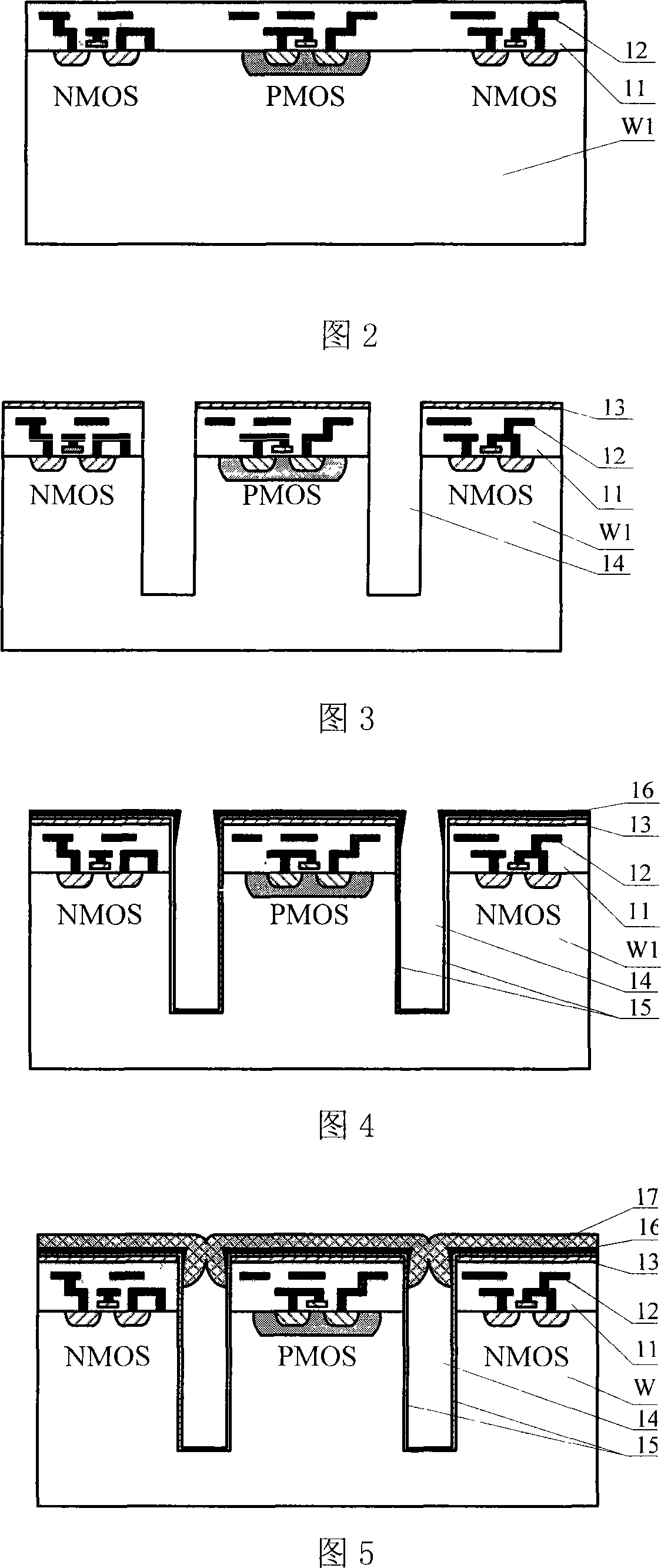

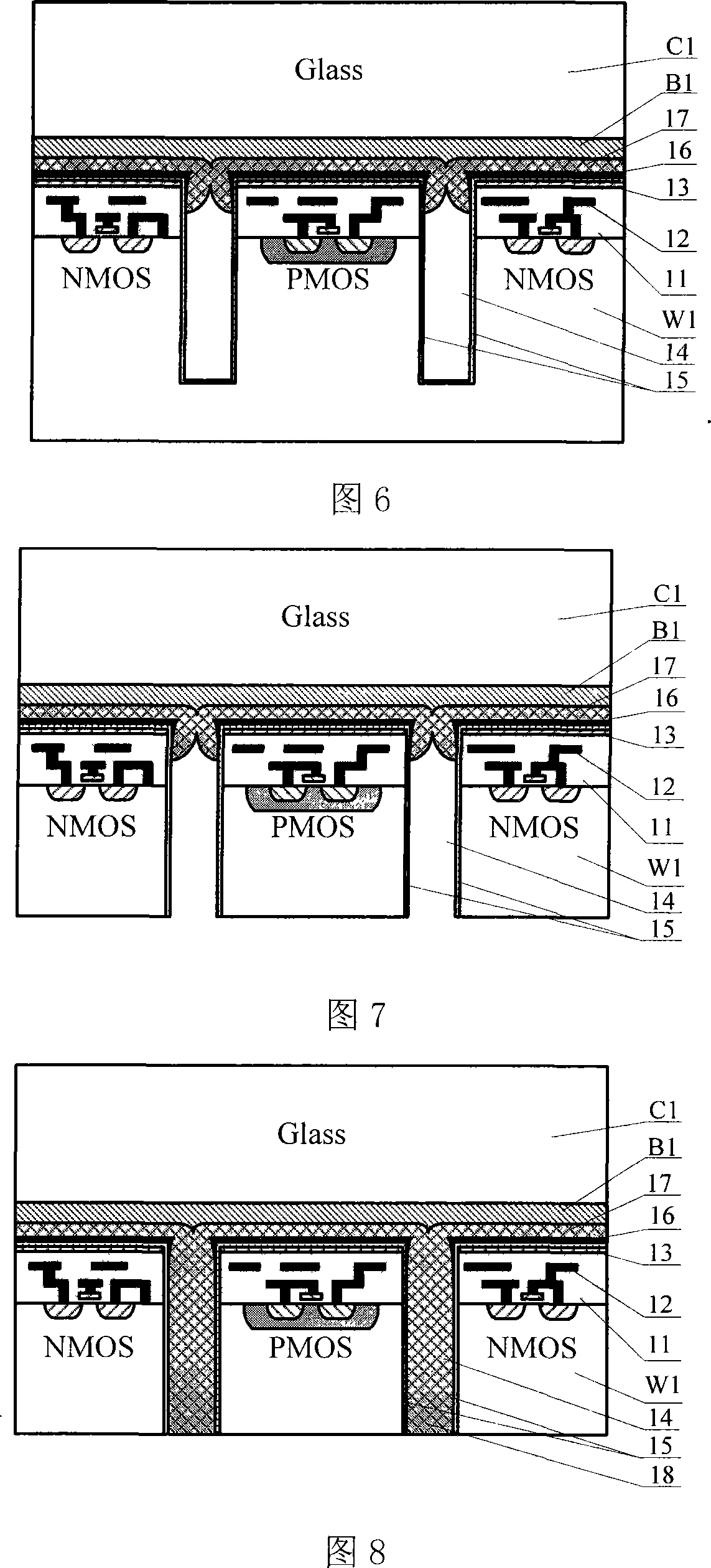

[0037]The present invention provides a high aspect ratio three-dimensional vertical interconnection and three-dimensional integrated circuit realization method. For the purpose of the present invention, the present invention is achieved by first deep etching by DRIE and then bonding the auxiliary wafer and thinning the device wafer. Consistent etching of through holes with different aspect ratios and avoiding lateral etching, using double-sided deposition of insulating layer, diffusion barrier layer and electroplating seed layer to solve the internal insulating layer, diffusion barrier layer and electroplating seed layer of high aspect ratio through holes The problem of difficult deposition, and the bottom-up electroplating process to fill the through holes to overcome the problem that the single-sided Damascus electroplating high aspect ratio structure is prone to gaps.

[0038] The embodiments of the present invention will be described in further detail below in conjunction with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com