H face sectoral horn antenna including filter function

A technology of horn antenna and filter, which is applied in the microwave field, can solve the problems that metal horn antennas are not easy to be integrated on a plane, and achieve the effects of high directivity, reduced production cost, and reduced volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

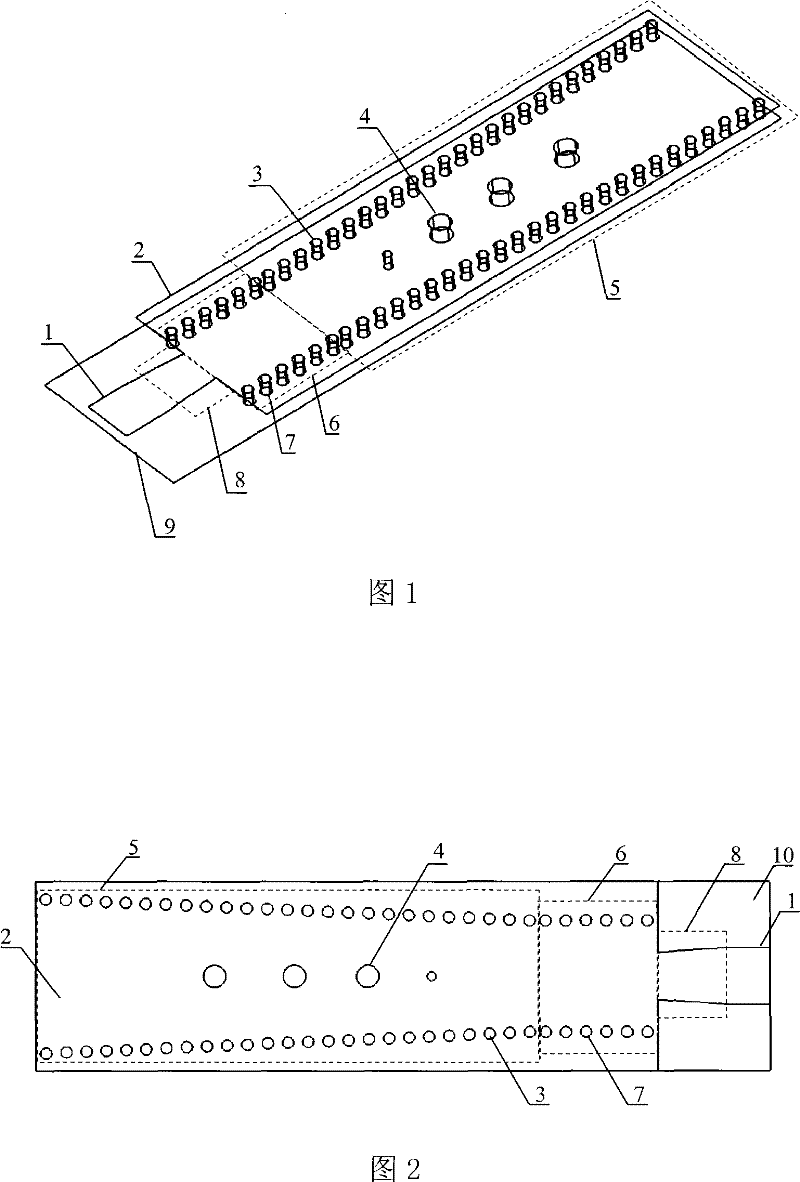

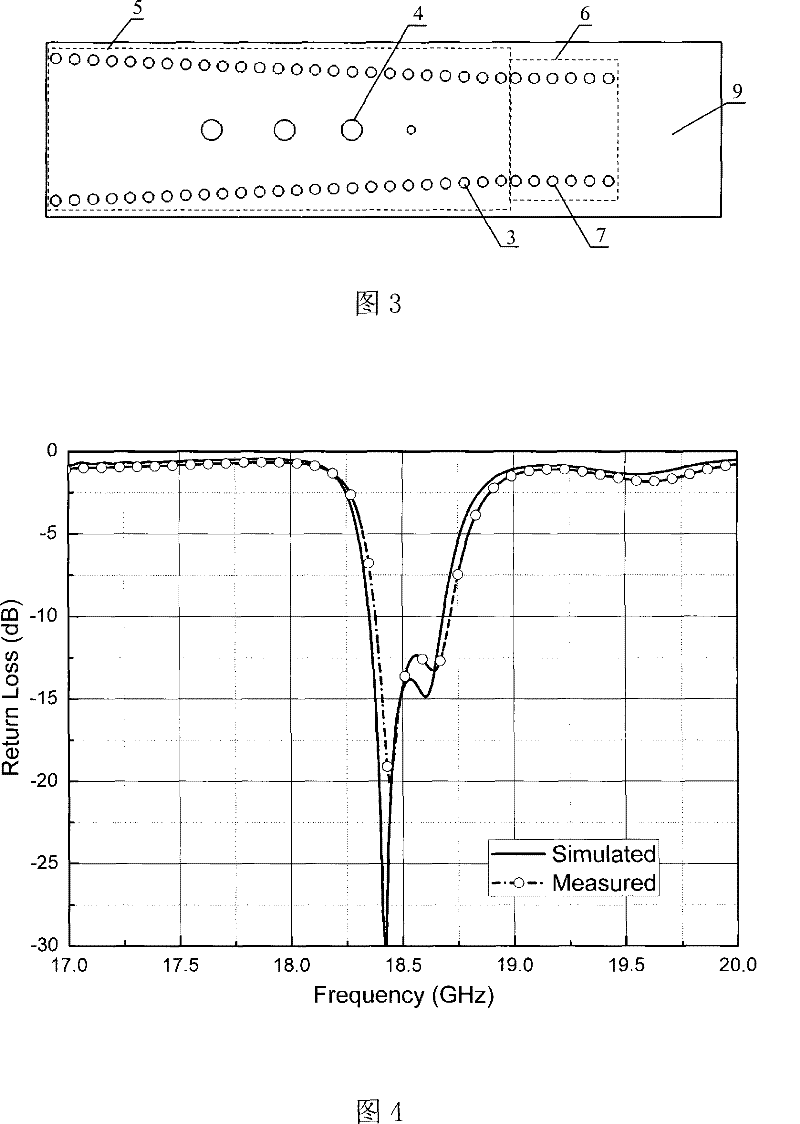

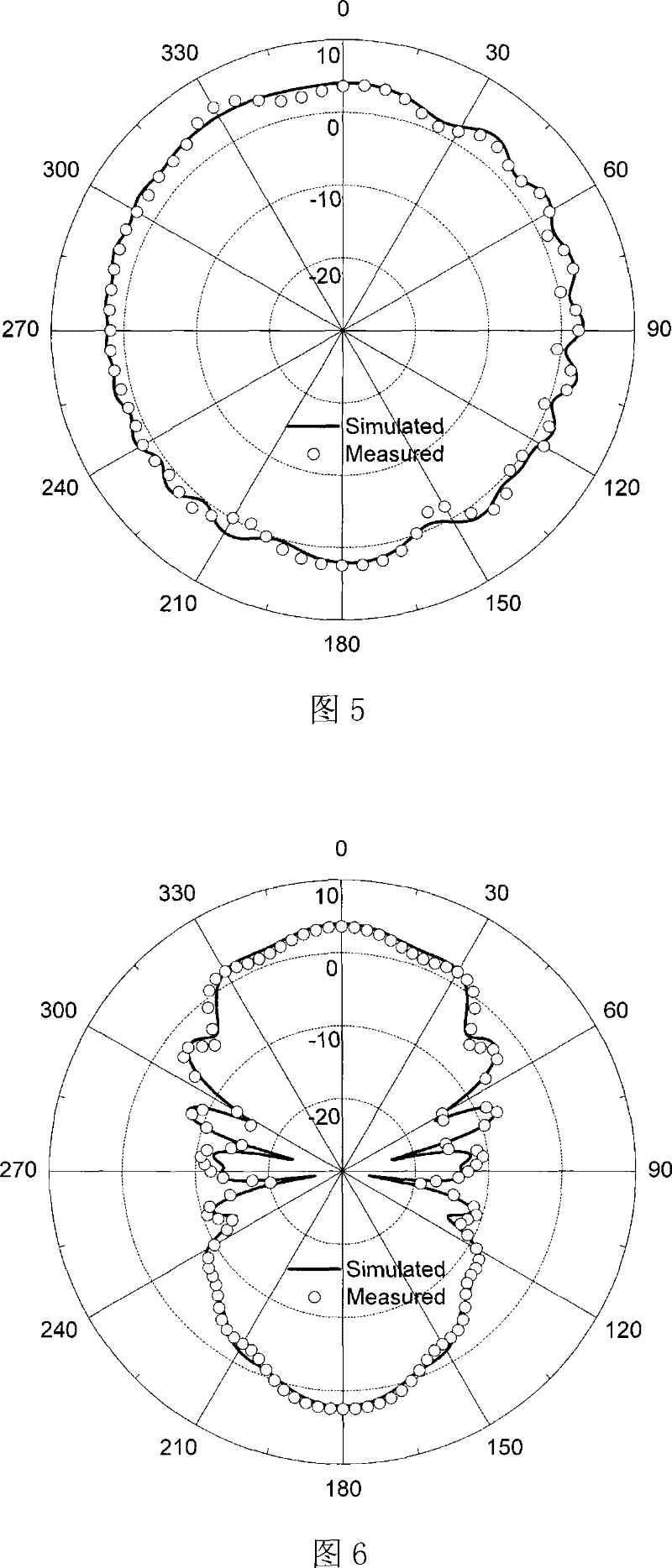

[0020] Such as figure 1 As shown, the H-face fan-shaped horn antenna including the filter function includes a Rogers5880 dielectric substrate 10 with a thickness of 1.575 mm. The two sides of the dielectric substrate 10 are coated with metal layers, which are respectively the upper metal layer 2 and the lower metal layer 9, wherein the lower metal layer Layer 9 serves as the stratum. Such as figure 2 , the upper metal layer 2 is etched with a microstrip line 1 for power feeding, and a trapezoidal converter 8 in the form of a microstrip. The output end of the ladder converter 8 is connected to the upper metal layer 2 constituting the substrate integrated waveguide, and the input end extends outward , as the microstrip line 1. The length and width of the microstrip line 1 are 6 mm and 5 mm respectively, the length of the trapezoidal converter 8 is 6 mm, and the width of the end connected to the metal layer 2 on the integrated waveguide on the substrate is 4.2 mm. Through the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com