Technology and apparatus for treating oil-containing alkaline waste water

A technology for treating process and waste water, which is applied in biological water/sewage treatment, flotation water/sewage treatment, neutralization water/sewage treatment, etc. It can solve the problem that it is not enough to realize the automatic long-term stable operation of the system and the inability to achieve advanced treatment for a long time , Non-compliance with environmental protection requirements and other issues, to achieve the effect of compact structure, small investment and convenient management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

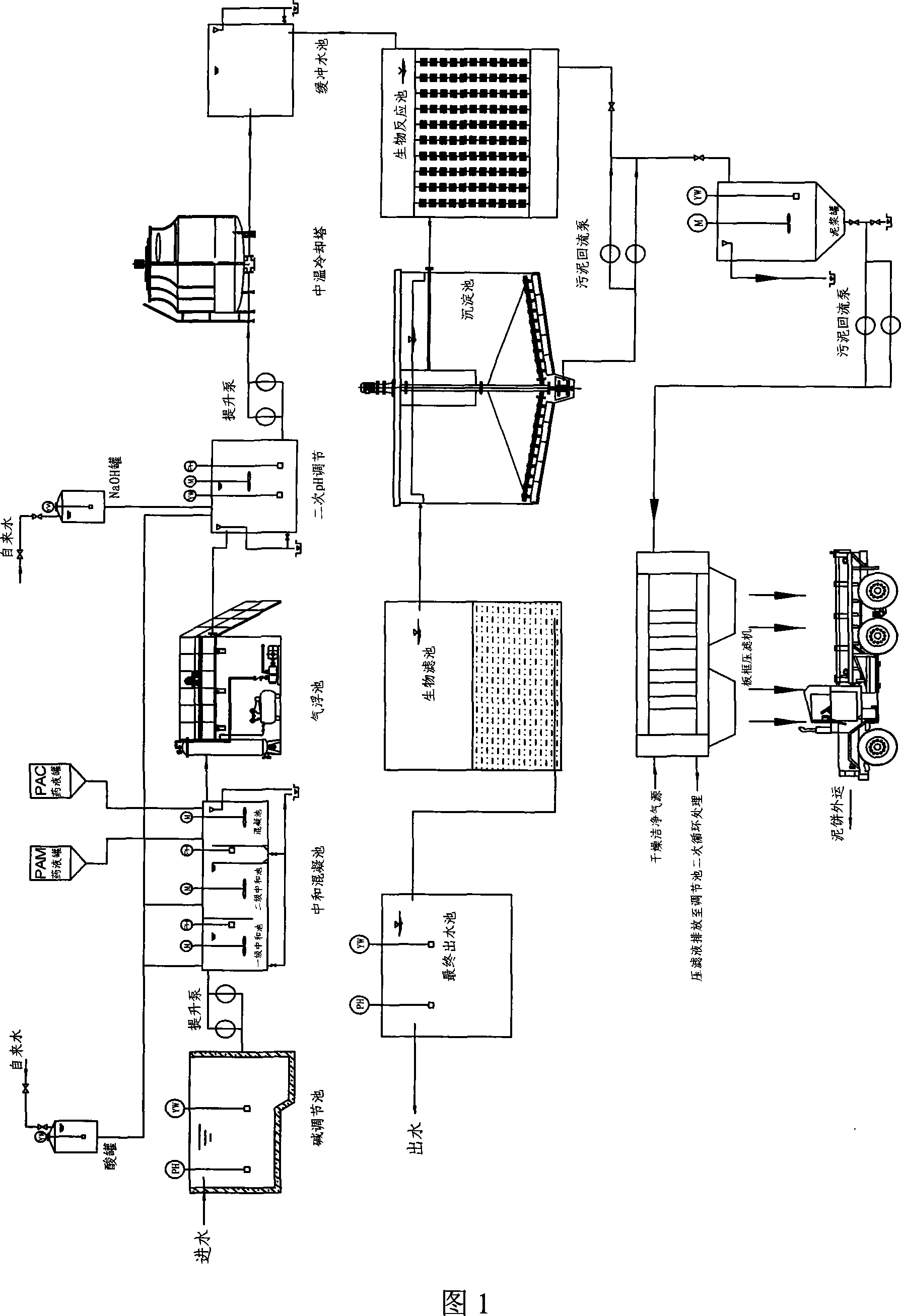

[0018] Below in conjunction with accompanying drawing, process of the present invention is described in detail:

[0019] 1) Alkaline wastewater treatment: the oily alkaline wastewater discharged from the unit flows into the alkali adjustment tank, where a pH meter and a liquid level gauge YW are installed.

[0020] PH adjustment: the effluent from the alkali adjustment tank is pumped into the first-level neutralization tank by a lift pump, and reacts with alkaline wastewater by adding acidic water in the first-level neutralization tank. The PH meter is controlled by frequency conversion, and the dosage is calculated and confirmed by PLC through mathematical models. The PLC signal comes from the pH value in the alkali adjustment pool and acid tank.

[0021] Fine-tuning: the effluent from the primary neutralization tank enters the secondary neutralization tank, and in the secondary neutralization tank, there are two other sets of spent acid and alkali pumps with a smaller flow r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com