Lndium antimonide opto-electronic sensor array quiescent operating point auto-calibration device

A technology of photoelectric sensor and static working point, which is applied in the field of photoelectric detection technology and electronics, and can solve the problems of consuming manpower and material resources, difficulties, unstable temperature coefficient of sensors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

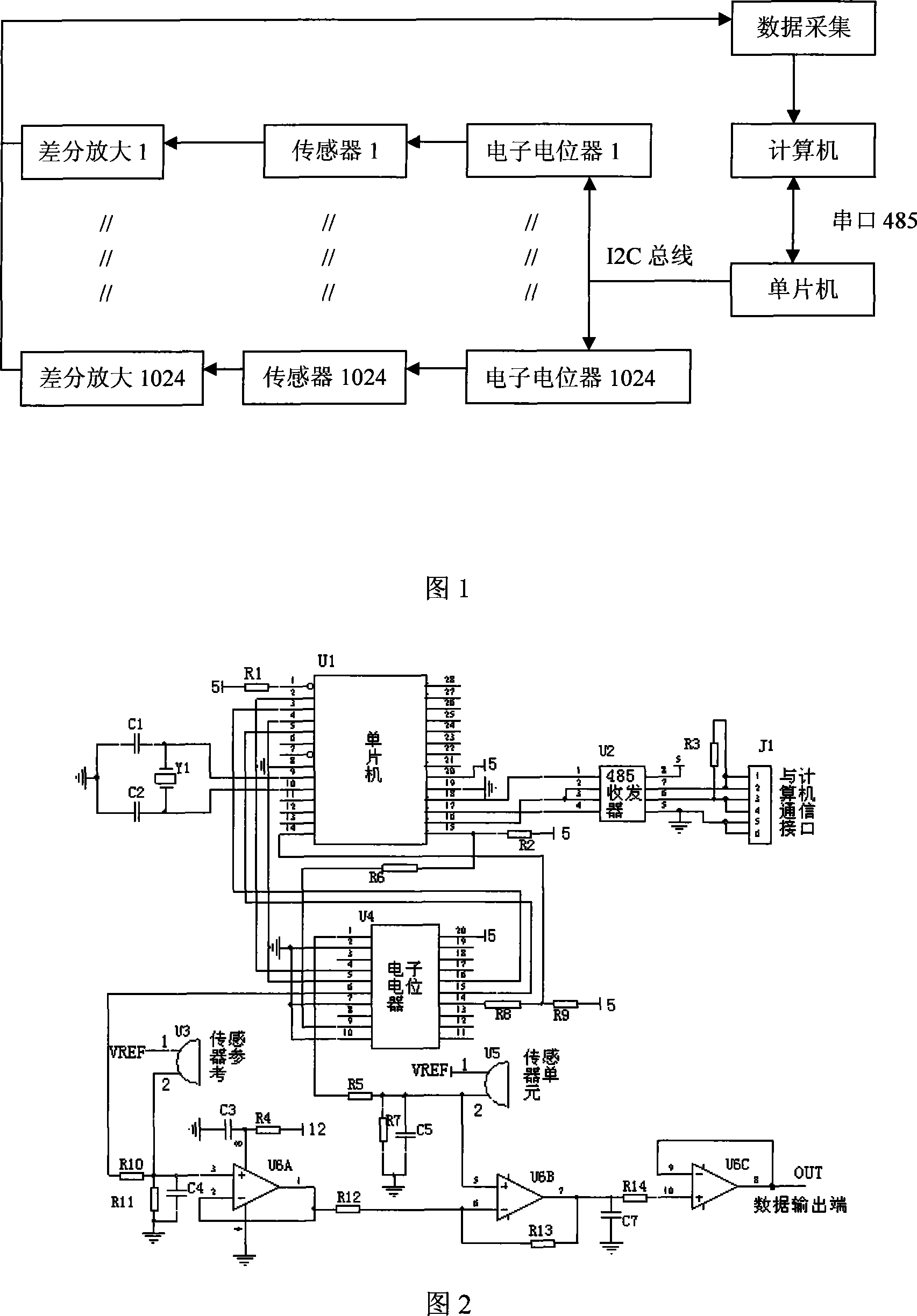

[0014] See Figure 1 and Figure 2.

[0015] In Figure 2, U1 is the PIC16F876A single-chip microcomputer of Microchip Company; U2 is the RS-485 differential bus transceiver SN65LBC184; U3 is the reference of the indium antimonide sensor; U4 is the electronic potentiometer X9241AYP; U5 is the indium antimonide sensor unit; U6 is the operational amplifier.

[0016] The 2(RA0), 3(RA1), 4(RA2), 5(RA3) pins of the microcontroller are respectively connected to the 4(A0), 16(A1), 5(A2), 15(A3) of the electronic potentiometer X9241AYP Pin, as the address line of X9241AYP.

[0017] The 26th pin of the MCU is connected with the 1st pin of SN65LBC184, the 24th pin of the MCU is connected with the 4th pin of SN65LBC184 as the serial port communication line; the 25th pin of the MCU is connected with the 2nd and 3rd pins of the SN65LBC184 as the transceiver control line of the serial port ; R3 is the matching resistor; J1 is the communication interface between the microcontroller and the com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com