Ultra-hydrophobic processing method for polytetrafluoroethylene thin film

A technology of polytetrafluoroethylene and a processing method, applied in the field of super-hydrophobic processing of polytetrafluoroethylene films, can solve problems such as loss of protection ability, and achieve the effects of low cost, significant economic and social benefits, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

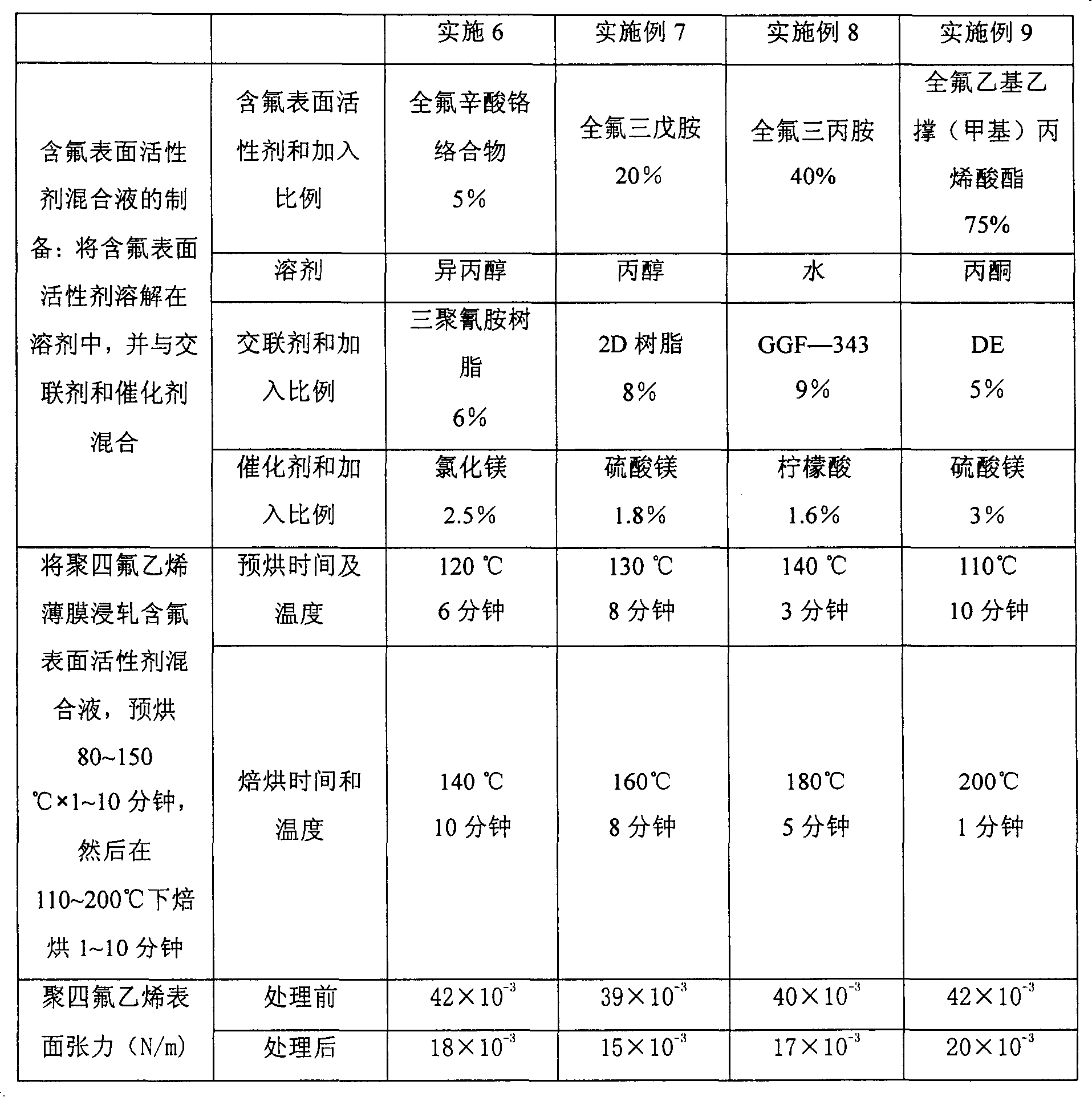

Examples

Embodiment 1

[0029] a. Preparation of fluorine-containing surfactant mixture: Dissolve perfluoroethylethylene (meth)acrylate in butanone solvent, and mix with crosslinking agent 2D resin and catalyst magnesium chloride, wherein perfluoroethylethylene The addition amount of vinyl (meth)acrylate is 15% of the mass of butanone, and the addition amounts of crosslinking agent 2D resin and catalyst magnesium chloride are respectively 3% and 0.1% of the mass of butanone.

[0030] b. Pad the polytetrafluoroethylene film with the fluorine-containing surfactant mixture, pre-bake it at 100°C for 2 minutes, and then bake it at 180°C for 2 minutes.

[0031] The surface tension of the PTFE microporous film was changed from that before treatment to 42×10 -3 N / m dropped to 19×10 after treatment -3 N / m.

Embodiment 2

[0033] a. Preparation of fluorosurfactant mixture: Dissolve sodium perfluorooctane sulfonate in methyl ethyl ketone solvent, mix with crosslinking agent melamine resin and catalyst citric acid, wherein the addition of sodium perfluorooctane sulfonate The amount is 50% of the mass of butanone, and the addition amounts of the crosslinking agent melamine resin and catalyst citric acid are respectively 10% and 4% of the mass of butanone.

[0034] b. Pad the polytetrafluoroethylene film with the fluorine-containing surfactant mixture, pre-bake it at 110°C for 3 minutes, and then bake it at 170°C for 3 minutes.

[0035] The surface tension of the PTFE microporous film was changed from that before treatment to 43×10 -3 N / m dropped to 16×10 after treatment -3 N / m.

Embodiment 3

[0037] a. Preparation of fluorosurfactant mixture: Dissolve ammonium perfluorooctane sulfonate and perfluorotriethylamine in methanol solvent, and mix with crosslinking agent EH and catalyst magnesium sulfate, wherein perfluorooctane sulfonate The mass ratio of ammonium nitrate and perfluorotriethylamine is 1:1, the sum of the two is 60% of the methanol mass, and the addition of the crosslinking agent EH and catalyst magnesium sulfate is 4% and 1% of the methanol mass respectively.

[0038] b. Pad the polytetrafluoroethylene film with the fluorine-containing surfactant mixture, pre-bake it at 80°C for 1 minute, and then bake it at 110°C for 10 minutes.

[0039] The surface tension of PTFE microporous film was changed from 38×10 before treatment -3 N / m drops to 15×10 after treatment -3 N / m.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com