Method for preparing high deacetylate degree and high viscosity chitosan by using shrimp shell

A technology of high deacetylation degree and chitosan, which is applied in the field of preparing high deacetylation degree and high viscosity chitosan by using shrimp shells, can solve the problems of low utilization rate of shrimp shells, low product purity and high production cost, and achieves The effect of good decolorization effect, high viscosity and short reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

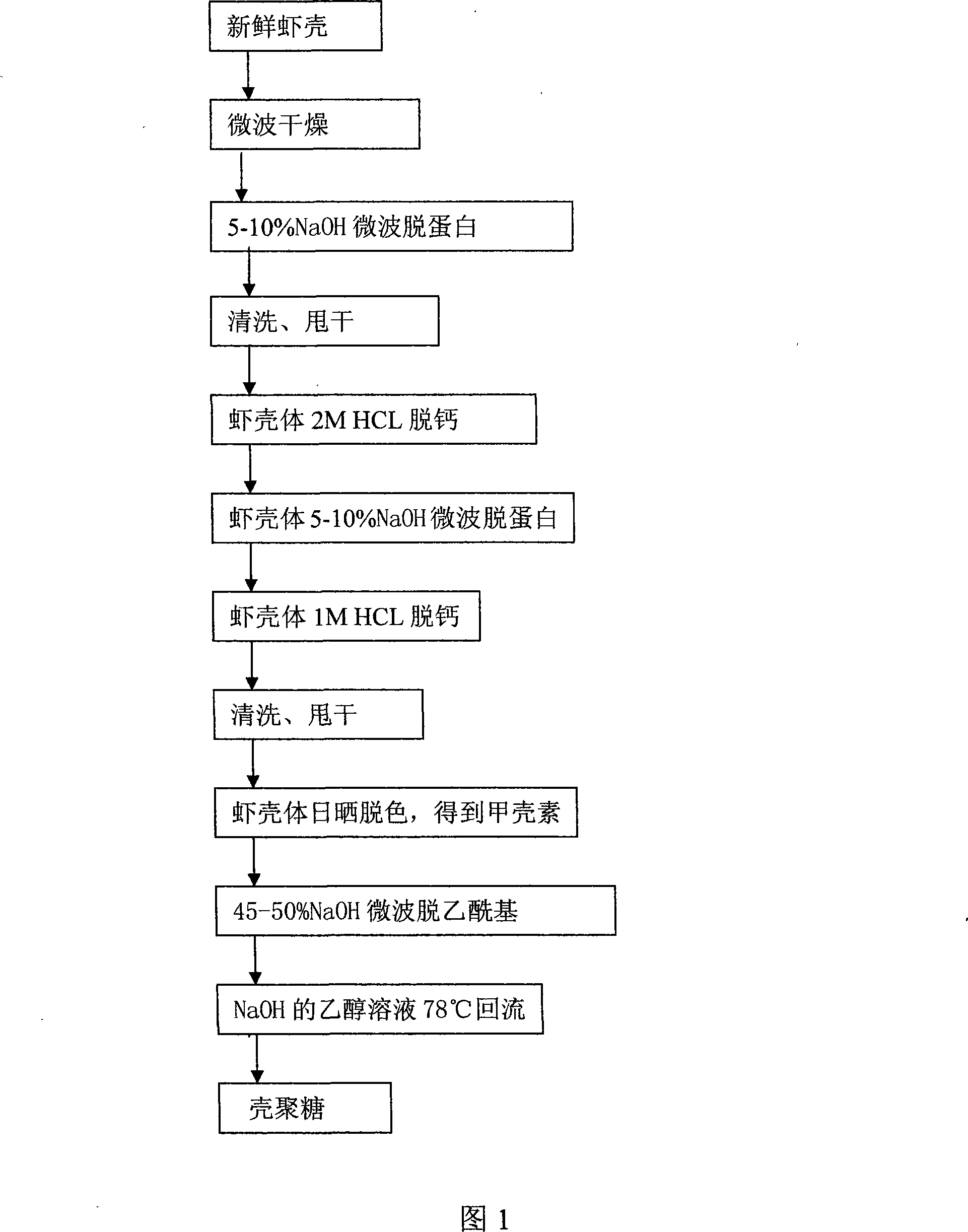

Image

Examples

Embodiment 1

[0022] Example 1: After washing and draining the fresh shrimp shells, place them in a microwave oven, control the temperature at 80°C, and heat for 15 minutes; then break the shrimp shells and immerse them in a concentration of 10 at a ratio of material to liquid weight ratio of 1:15. % NaOH solution, put it in a microwave oven, control the temperature at 100°C, take it out and filter after heating for 10 minutes, rinse the shrimp shell with water until it is neutral and dry it to obtain a deproteinized shrimp shell; Immerse in 2mol / L HCl solution and soak for 24 hours according to the ratio of feed-to-liquid weight ratio of 1:12, then filter and spin dry to obtain decalcified shrimp shells; The decalcified shrimp shell is treated once again with 10% NaOH solution, filtered, rinsed with clear water until neutral, placed in 1mol / L HCL solution according to the ratio of material to liquid weight ratio of 1:12, soaked for 24 hours, Filter, rinse the shrimp shells until neutral an...

Embodiment 2

[0024] After washing and draining the fresh shrimp shells, place them in a microwave oven, control the temperature at 80°C, and heat for 10 minutes; then break the shrimp shells and immerse them in a 5% NaOH solution at a ratio of 1:10 by weight of material to liquid Then put it in a microwave oven, control the temperature at 100°C, take it out and filter after heating for 15 minutes, rinse the shrimp shell with clean water until it is neutral and dry it to obtain the deproteinized shrimp shell; Ratio of 1:12 was immersed in 2mol / L HCl solution and soaked for 24 hours, then filtered and dried to obtain decalcified shrimp shells; The ratio is treated once more with 5% NaOH solution, filtered, rinsed with clear water until neutral, placed in 1mol / L HCL solution according to the ratio of material to liquid weight ratio of 1:12, soaked for 24 hours, filtered, and the shrimp shell Rinse the body until it is neutral and dry it; decolorize the above-mentioned shrimp shells in the sun...

specific Embodiment 3

[0025] After washing and draining the fresh shrimp shells, place them in a microwave oven, control the temperature at 100°C, and heat for 12 minutes; then break the shrimp shells and immerse them in an 8% NaOH solution at a ratio of 1:12 by weight of material to liquid Then put it in a microwave oven, control the temperature at 100°C, take it out and filter after heating for 12 minutes, rinse the shrimp shell with clean water until it is neutral and dry it to obtain the deproteinized shrimp shell; Ratio of 1:12 was immersed in 2mol / L HCl solution and soaked for 24 hours, then filtered and dried to obtain decalcified shrimp shells; The ratio is treated once more with 8% NaOH solution, filtered, rinsed with clear water until neutral, placed in 1mol / L HCL solution according to the ratio of material to liquid weight ratio of 1:12, soaked for 24 hours, filtered, and the shrimp shell Rinse the body until it is neutral and dry it; decolorize the above-mentioned shrimp shells in the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com