Polyethersulfone ketone modified resin based friction material

A technology of modified resin and polyethersulfone ketone is applied in the field of friction materials, which can solve the problems of inability to meet the requirements of modern friction materials, high brittleness of phenolic resin, limited heat resistance, etc., to achieve stable friction coefficient, low product wear, The effect of braking comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

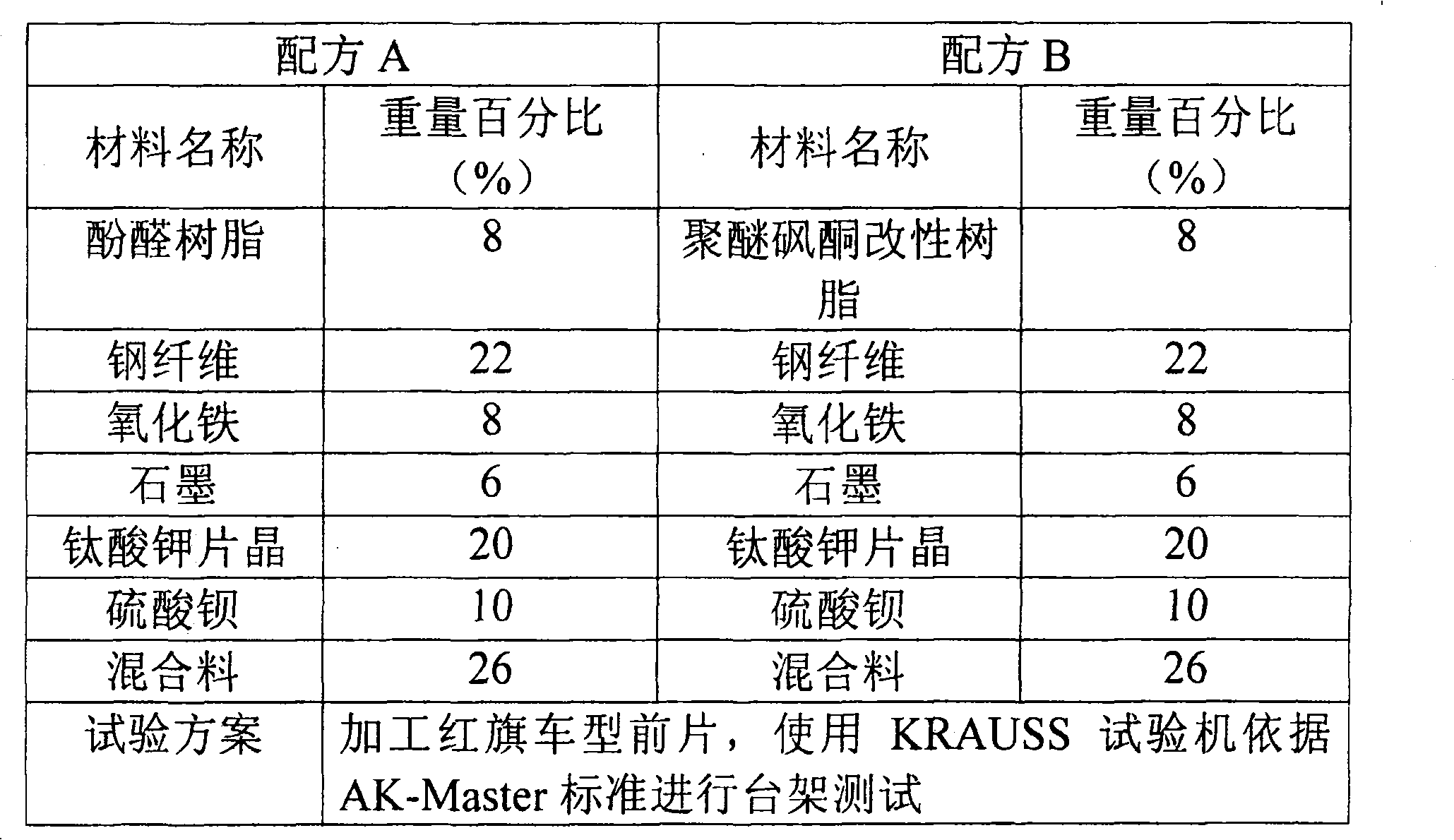

[0008] For the problems existing in the prior art, according to the content of the invention, two groups of formulas (A formula and B formula) have been designed and tested. The experimental scheme and experimental results are as follows:

[0009]

[0010] According to the above formula design, the samples are processed and tested according to the following production process: Mixing→forming hot pressing→heat treatment→flat grinding→painting→drying→installing accessories→printing and packaging

[0011] test results

[0012] According to the analysis of experimental data, the friction material product of unmodified phenolic resin (formula A) has high hardness, and when performing the decay procedure, the decay rate is as high as 35%, the high-speed performance is poor, the friction coefficient is 0.22, and there is noise during the experiment Produced; while the polyether sulfone ketone modified resin friction material (formula B) has a significant improvement in the decline...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com