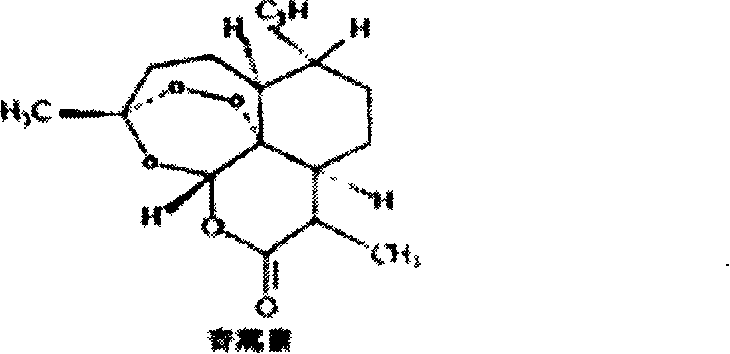

Technical new method for extracting artemisinin from sweet wormwood plants by ultrasonic assistance

A technology for medium and auxiliary extraction of artemisinin, applied in plant raw materials, plant/algae/fungi/moss components, pharmaceutical formulations, etc., can solve the problem of narrow selection of supercritical extraction solvents, high industrial application costs, and limited industrial applications, etc. problems, to achieve the effect of improving equipment processing capacity and efficiency, convenient equipment maintenance, and shortening extraction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The best technical solutions obtained are:

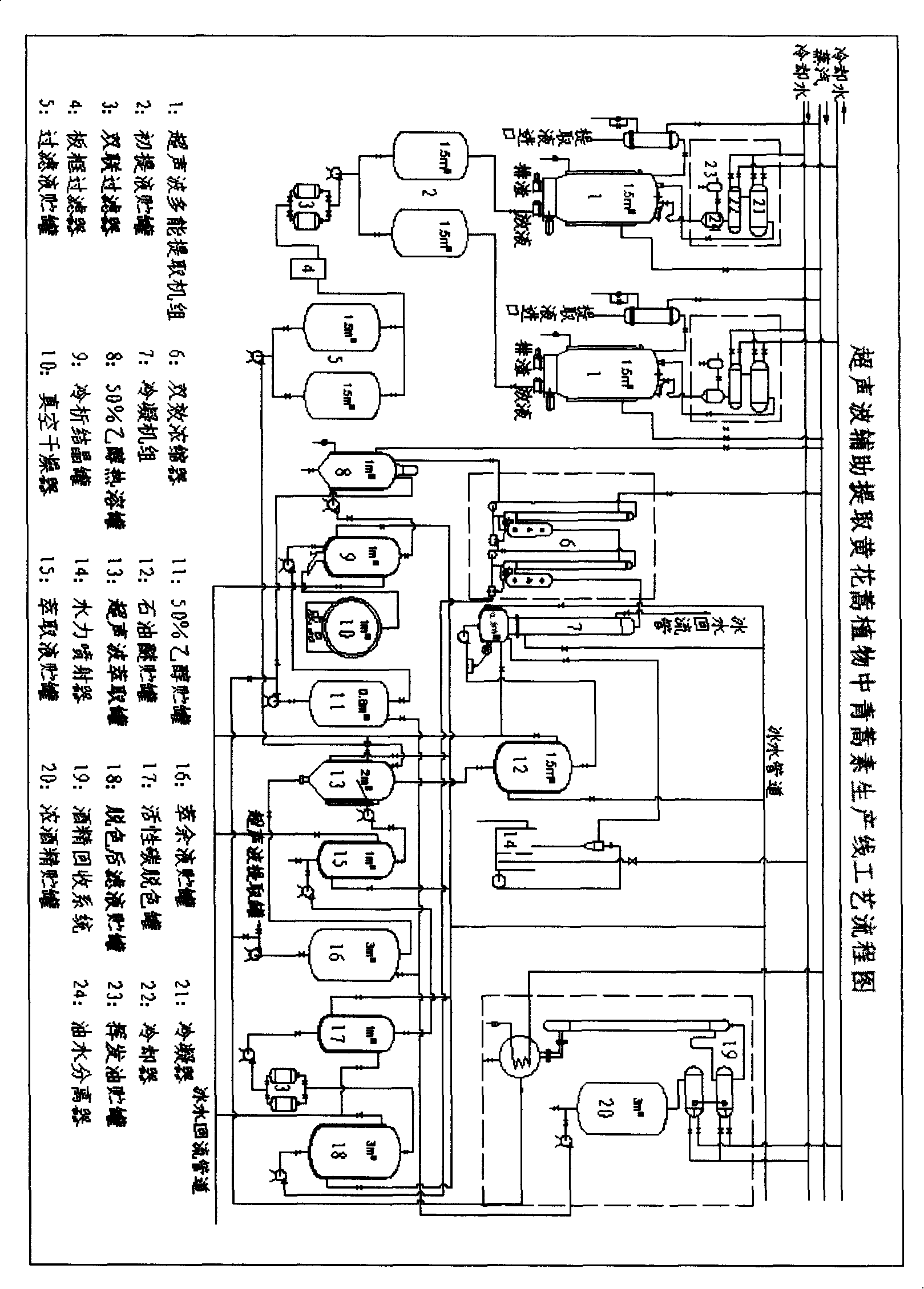

[0016] The stems and leaves of the Artemisia annua plant were dried at 60°C for 24 hours, pulverized by a pulverizer, and sieved to obtain a 60-80 mesh powder. Pack into the ultrasonic extraction kettle (ultrasonic Chinese medicine extractor: China Ningbo Zhenguo Pharmaceutical Equipment Manufacturing Co., Ltd., model: TCLX200) and carry out material ultrasonic extraction, add 80% ethanol, solid-liquid ratio (Kg: L) 1: 15-17, mix. Ultrasonic generation method: other excitation ultrasonic sounding device, radial vibration columnar transducer; ultrasonic power: 1000W; ultrasonic frequency: 35kHz; extraction method: interval 2min, ultrasonic action once, ultrasonic action time 3min, total extraction time 30min; extraction Temperature: 40°C; stirring method: air-lift stirring; ultrafiltration of the extract, ultrasonic extraction of an equal volume of petroleum ether at 30-60°C. Ultrasonic extraction conditions are as follows: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com