Method for manufacturing tin solder projection

A technology for solder bumps and a manufacturing method, which is applied in the manufacture of semiconductor/solid-state devices, electrical components, and electrical solid-state devices, etc., can solve problems such as uneven distribution of solder bumps, and achieve the effect of high strength and uniform distribution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

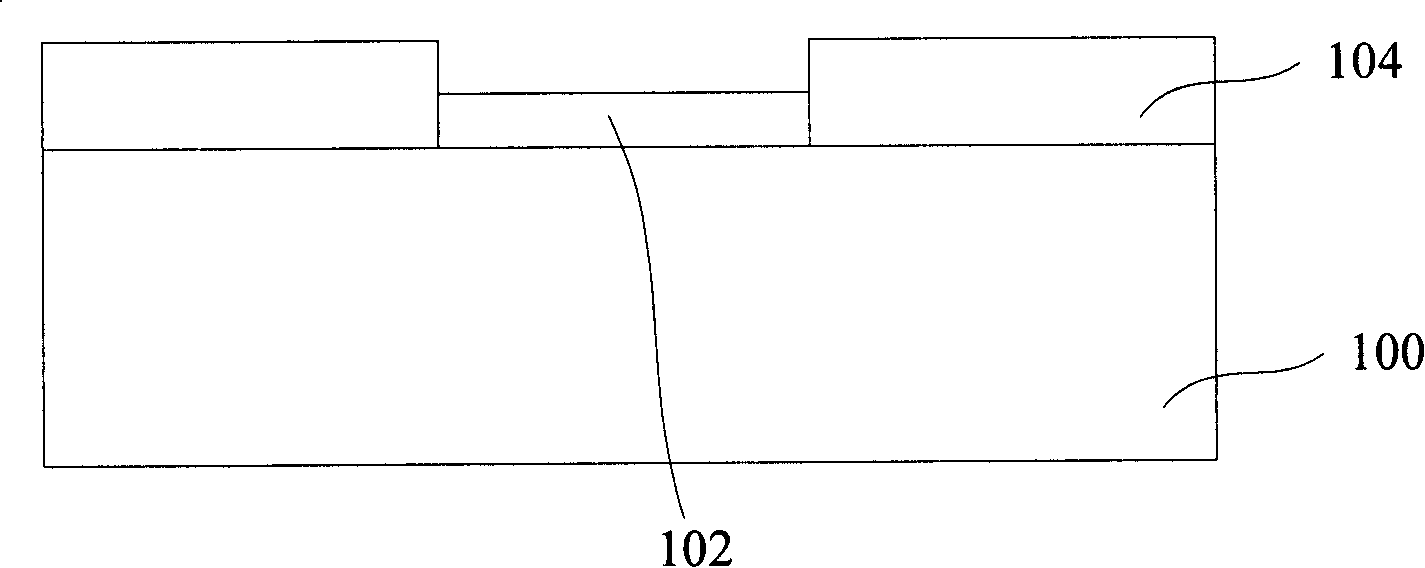

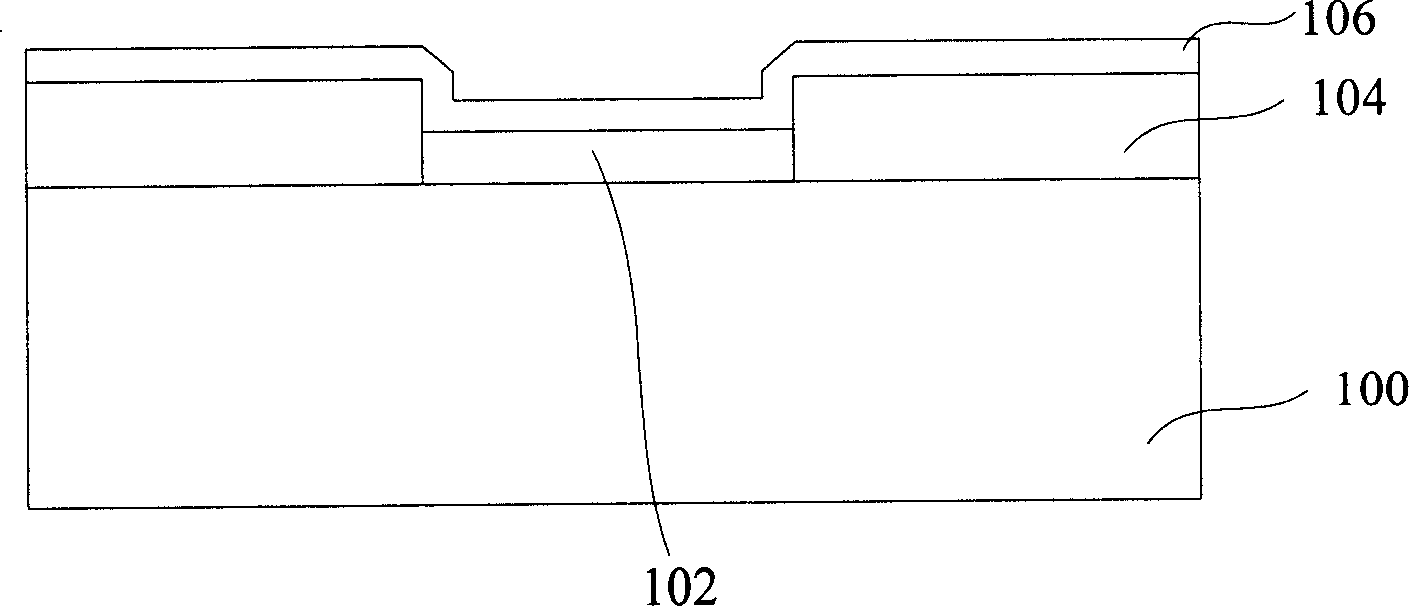

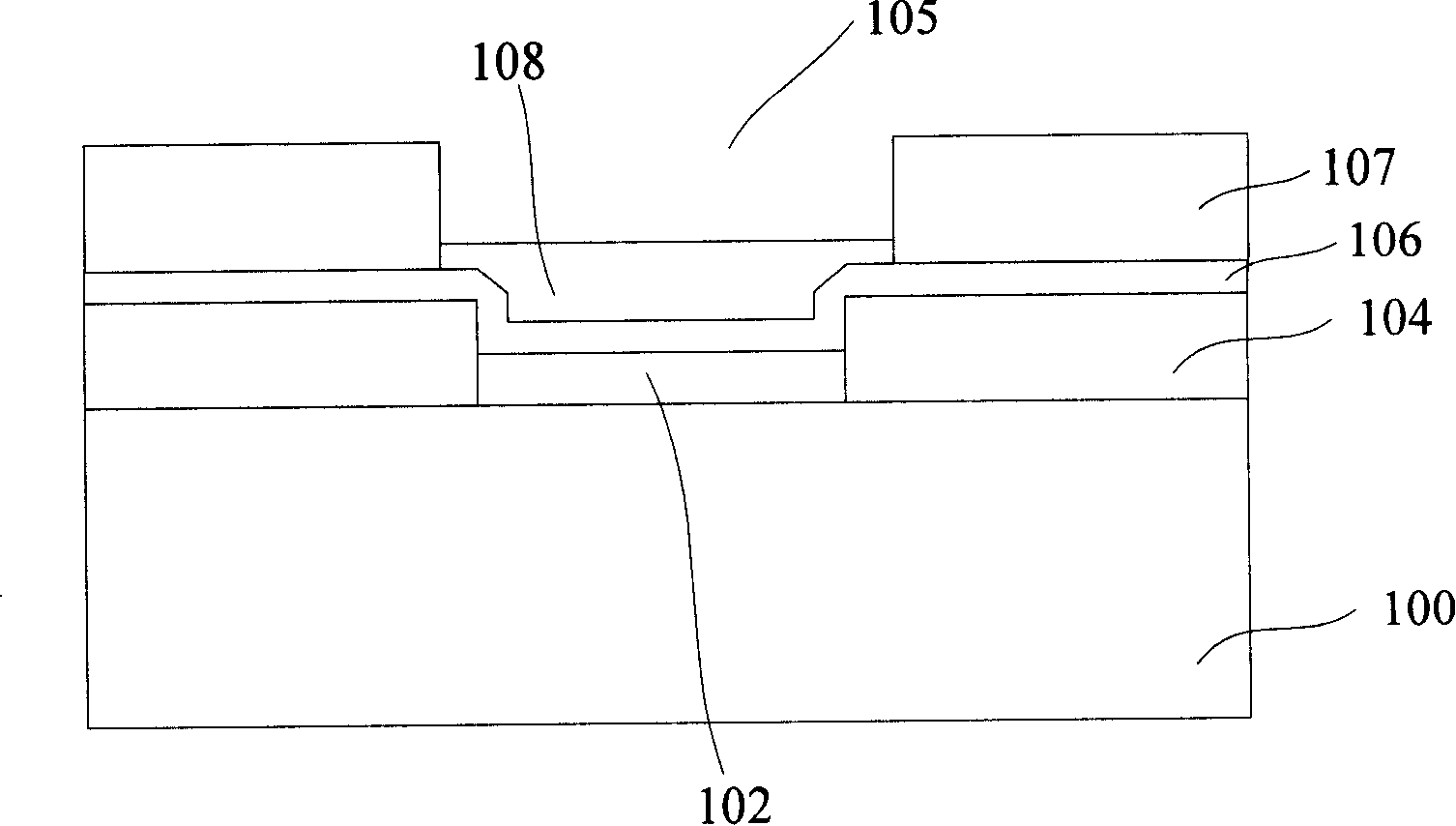

[0026] In order to make the above objects, features and advantages of the present invention more comprehensible, specific implementations of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0027] Image 6 It is a flow chart of the first embodiment of the manufacturing method of the solder bump of the present invention.

[0028] like Image 6 As shown, firstly, a semiconductor substrate (S100) is provided, the semiconductor substrate is one of monocrystalline silicon, polycrystalline silicon, and amorphous silicon, and the semiconductor substrate has completed the device manufacturing in the front stage and the metal interconnection in the back stage, Lead soldering bumps are formed on the surface of the semiconductor substrate, the soldering wires are aluminum, copper or aluminum-copper alloy, and a protective layer is formed on the surface of the semiconductor substrate other than the soldering wires, and the protectiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com