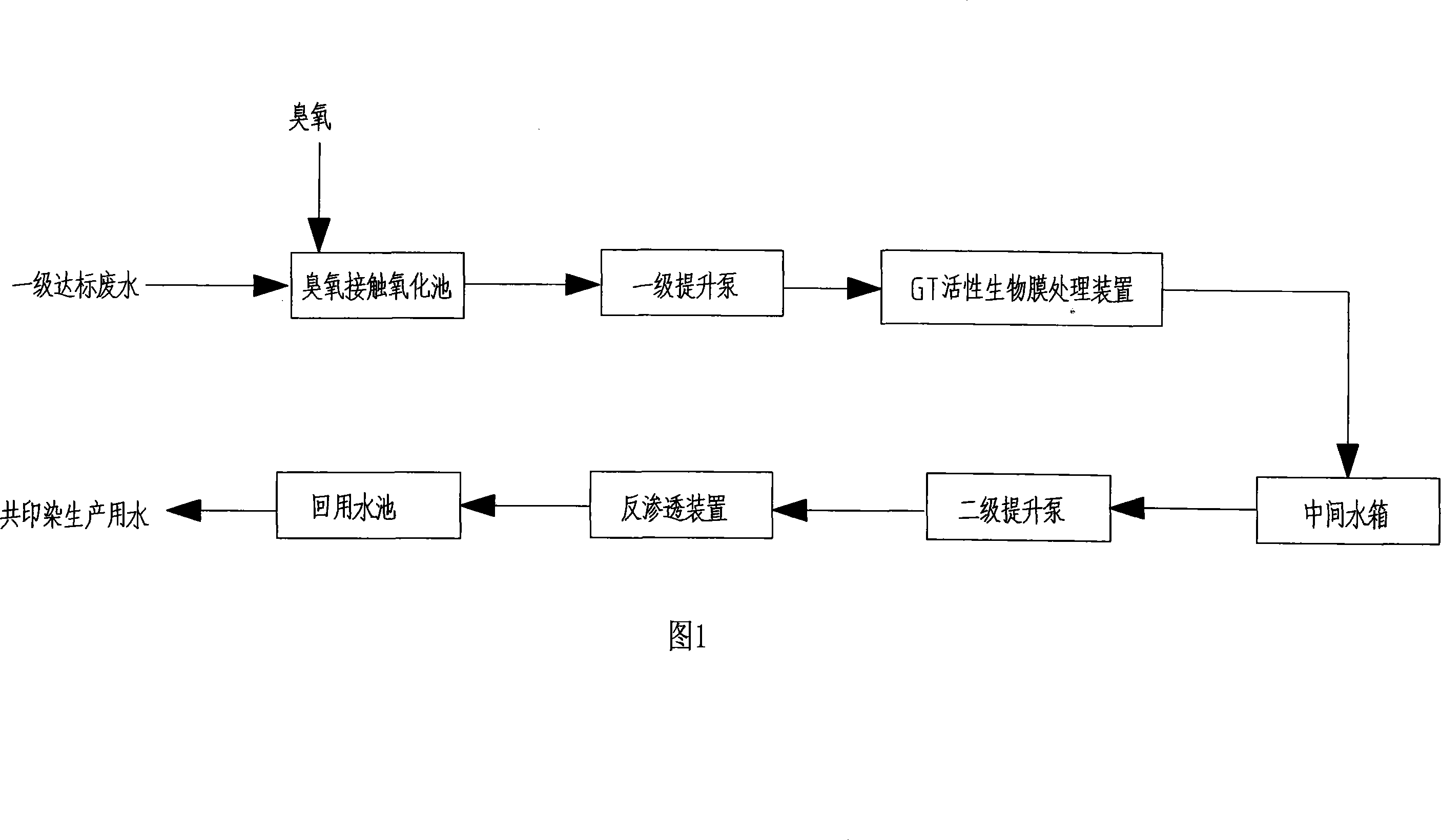

Recycling processing technique for dyeing and printing sewage

A technology of printing and dyeing sewage, technology, applied in biological water/sewage treatment, oxidized water/sewage treatment, water/sewage multi-stage treatment, etc. Good protection, strong filtering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0075] Use the printing and dyeing sewage that reaches the first-class discharge standard in general printing and dyeing factories, pass it into the pipeline, and first perform ozone contact oxidation treatment: add ozone in the water injector of the ozone contact oxidation tower, and the dosage of ozone is 5g / m 3 , The sewage is contacted and miscible with high-concentration ozone aqueous solution for 10 minutes in the contact oxidation tower. Ozone can oxidize part of the organic matter in the water, making it into a small molecular structure, and at the same time can achieve the purpose of disinfection and sterilization of the water body.

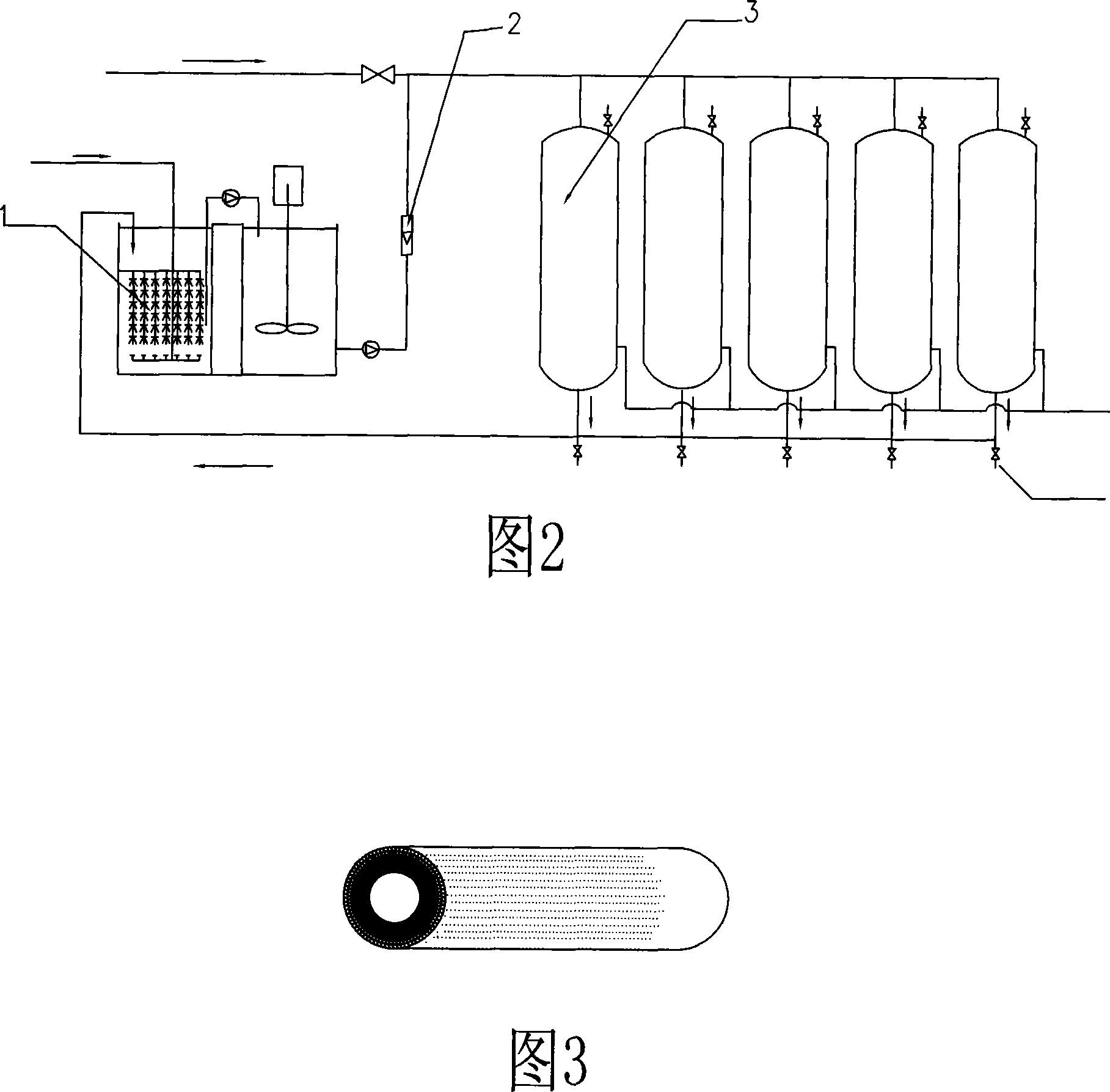

[0076] The pre-stage water treated by ozone contact oxidation is introduced into the pre-formed active biofilm device through the pipeline through the first-stage lift pump, and the effluent of printing and dyeing sewage after GT active biofilm treatment can reach the following indicators:

[0077] project

indicators

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com