Method for reducing sulfur content in gasoline

A technology of sulfur content and gasoline, applied in the petroleum industry, processing hydrocarbon oil, refining hydrocarbon oil, etc., can solve the problems of large heat source consumption, high price, loss of industrial application value, etc., to reduce the contact reaction time and ensure the desulfurization effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] This example is used to illustrate the method for reducing the sulfur content in gasoline provided by the present invention.

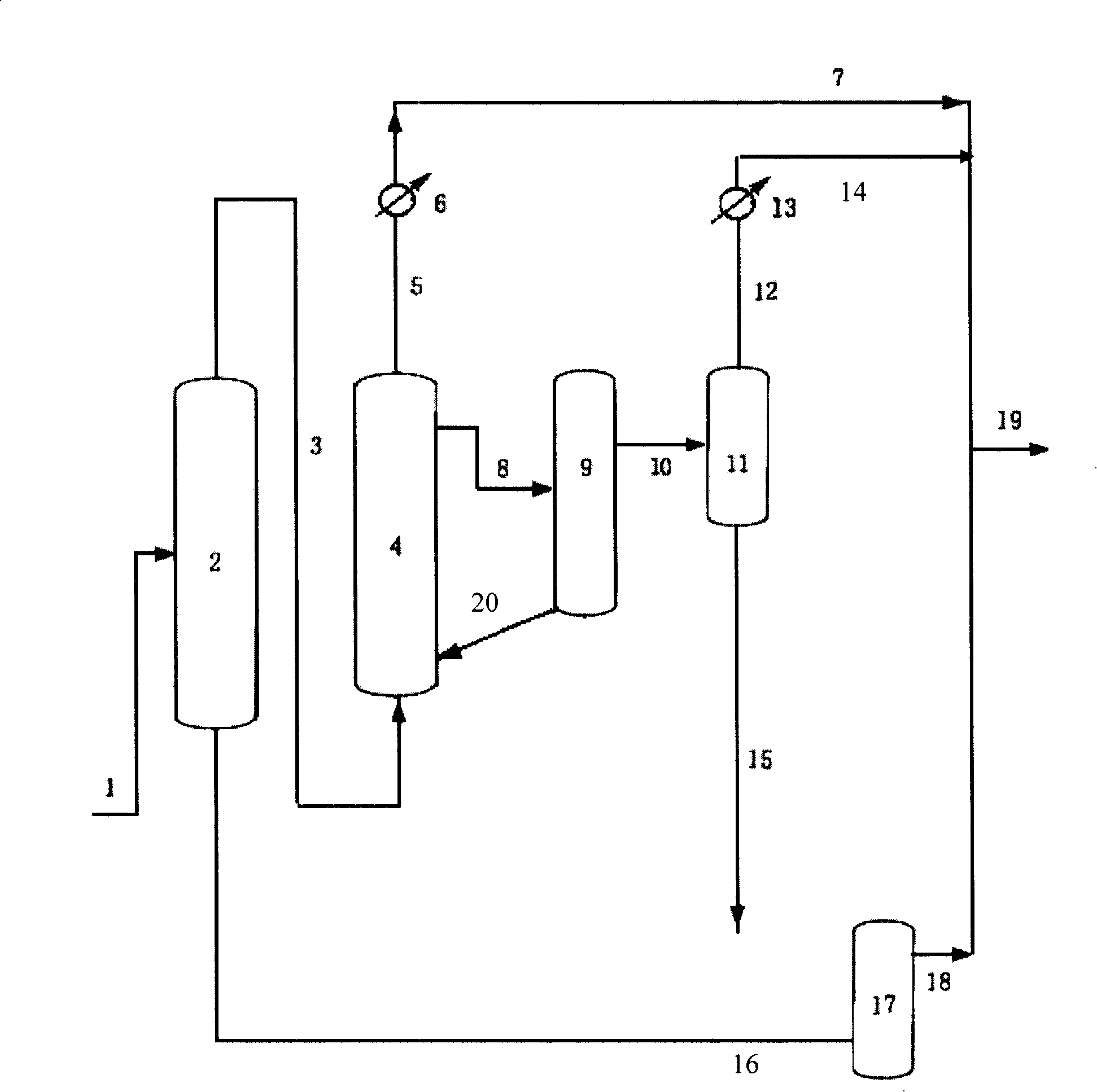

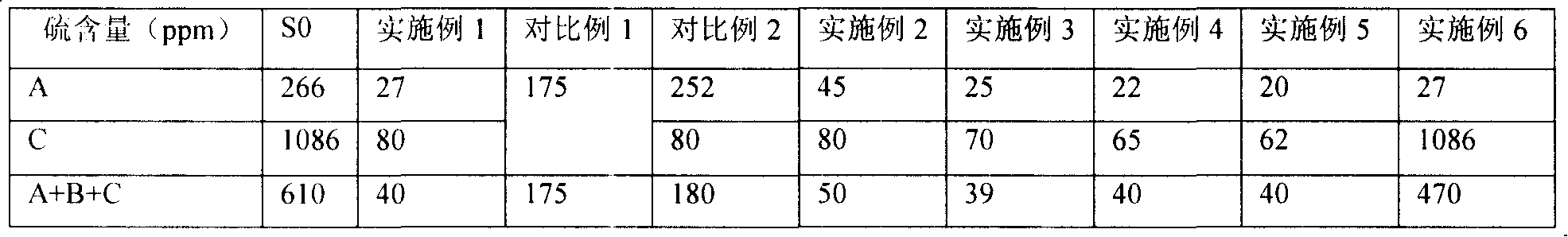

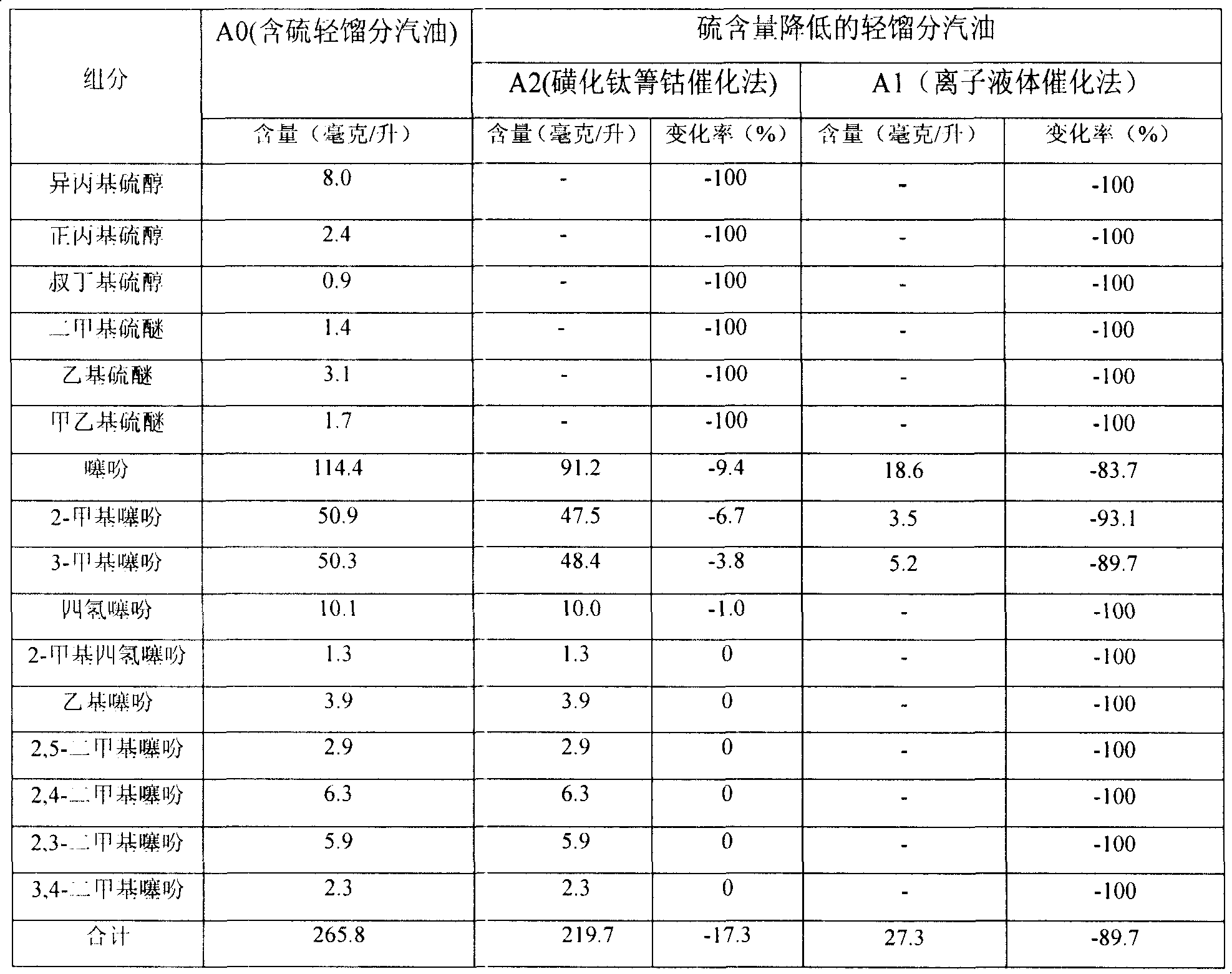

[0036] Such as figure 1Shown, in the bubble reactor 4 that effective volume is 50 milliliters, pack 10 grams of trimethylamine hydrochloride chloroaluminate type ionic liquid T22 (Xingpu Fine Chemical Co., Ltd.), inject high-boiling point in the sedimentation separator 9 Distillate oil, stop injecting when the liquid level of high boiling point distillate oil reaches the overflow port. Use a metering pump to feed the full fraction FCC gasoline (expressed as SO in Table 2, density: 0.7282 mg / liter, sulfur content: 610 ppm, distillation range: 10% is 36°C, 50% is 89°C, 90% is 160°C) Inject into the fractionation tower 2 from the middle through the pipeline 1 at a flow rate of 500 g / h, supply heat from the bottom of the fractionation tower 2, and cut the whole fraction catalytic cracked gasoline at 120°C to vaporize the light fraction gasoline wit...

Embodiment 2

[0044] This example is used to illustrate the method for reducing the sulfur content in gasoline provided by the present invention.

[0045] According to the method described in embodiment 1, the sulfur content in gasoline is reduced, and the difference is that 3 grams of cetyltrimethylammonium chloride aluminum chloride type ionic liquid C22 (Xingpu) are loaded into the bubble reactor 4 Fine Chemical Co., Ltd.), the countercurrent contact temperature in the bubble reactor was 150 ° C, and the contact time was 5 minutes. The content (weight fraction) of each fraction is shown in Table 1. The sulfur content of gasoline products with reduced sulfur content is shown in Table 2 by mixing light distillate gasoline A and gasoline distillate B with reduced sulfur content with heavy distillate gasoline C with reduced sulfur content.

Embodiment 3

[0047] This example is used to illustrate the method for reducing the sulfur content in gasoline provided by the present invention.

[0048] According to the method described in embodiment 1, the sulfur content in gasoline is reduced, and the difference is that 30 grams of pyridine hydrochloride chloroaluminate type ionic liquid P22 (Xingpu Fine Chemical Co., Ltd.) is loaded into the bubble reactor 4, and The countercurrent contact temperature in the bubble reactor was 80°C and the contact time was 10 minutes. The content (weight fraction) of each fraction is shown in Table 1. The sulfur content of gasoline products with reduced sulfur content is shown in Table 2 by mixing light distillate gasoline A and gasoline distillate B with reduced sulfur content with heavy distillate gasoline C with reduced sulfur content.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com