Nano composite anti-wear coating composition used for hot forging die and application thereof

A wear-resistant coating and nano-composite technology, which is applied in the field of surface engineering, can solve the problems of few types of matrix materials and single laser processing method, and achieve the effects of high cost performance, prolonged failure period and fast processing speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

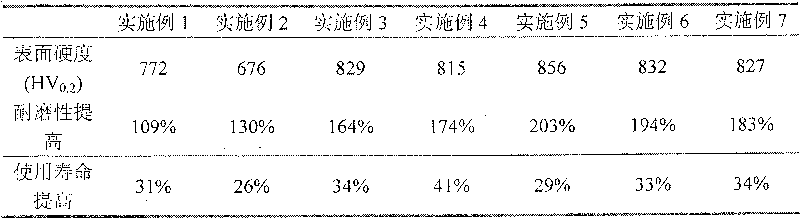

Examples

Embodiment 1

[0022] The nanocomposite wear-resistant coating was prepared on the H11 material mold. Before coating, it is necessary to degrease and clean the surface of the mold to be treated. After mixing the nano-alumina powder with a volume ratio of 1:4 and the single-wall carbon nanotube material, the amount of cobalt added is the nano-alumina powder and the single-wall carbon nanotube material. 40% of the mixing volume of the tube material, then add the binder novolak and fully stir and mix evenly, the ratio of the addition of the novolak to the mixing volume of the nano-alumina powder and the single-walled carbon nanotube material is 3: 1, the above-mentioned The mixture is pre-placed in the corresponding part of the mold, and the coating thickness is 0.5mm. The high-energy laser beam generated by the carbon dioxide laser is used to perform laser strengthening treatment on the coating. During the laser scanning process, the laser scanning area is simultaneously protected by inert gas,...

Embodiment 2

[0024] The nanocomposite wear-resistant coating was prepared on the H12 material mold. Before coating, it is necessary to degrease and clean the parts of the mold surface that need to be treated. Mix nano-silicon oxide powder with a volume ratio of 1:1 with multi-walled carbon nanotubes. The amount of cobalt added is the amount of nano-silicon oxide powder and multi-walled carbon nanotubes 50% of the mixing volume, then add the binder novolac and mix evenly, the ratio of the addition of the novolak to the mixing volume of the nano-silicon oxide powder and the multi-walled carbon nanotube material is 3: 1, the above-mentioned mixture is preset On the corresponding part of the mold, the coating thickness is 0.2mm, and the high-energy laser beam generated by the carbon dioxide laser is used to carry out laser strengthening treatment on the coating. During the laser scanning process, the laser scanning area is protected by synchronous inert gas. Argon is the protective gas, and the...

Embodiment 3

[0026] The nanocomposite wear-resistant coating was prepared on the H13 material mold. Before coating, it is necessary to degrease and clean the surface treatment part of the mold, mix nano-titanium oxide powder with a volume ratio of 1:2 with multi-walled carbon nanotube material, and add cobalt in the amount of nano-titanium oxide powder and multi-walled carbon nanotube material 43% of the mixing volume, then add the binder novolac and mix evenly, the ratio of the addition of the novolac to the mixing volume of the nano-titanium oxide powder and the multi-walled carbon nanotube material is 3: 1, the above-mentioned mixture is preset in For the corresponding part of the mold, the coating thickness is 0.3mm. The high-energy laser beam generated by the carbon dioxide laser is used to carry out laser strengthening treatment on the coating. During the laser scanning process, the laser scanning area is protected by synchronous inert gas. Helium is the protective gas. Laser process ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com