Outer lane sealant for hollow glass

A sealant and glass technology, applied in the field of sealant, can solve problems such as failure of insulating glass sealing system, loss of thermal insulation properties, waste of energy and resources, etc., and achieve low water vapor transmission rate, good anti-aging properties and anti-ultraviolet rays Features, energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

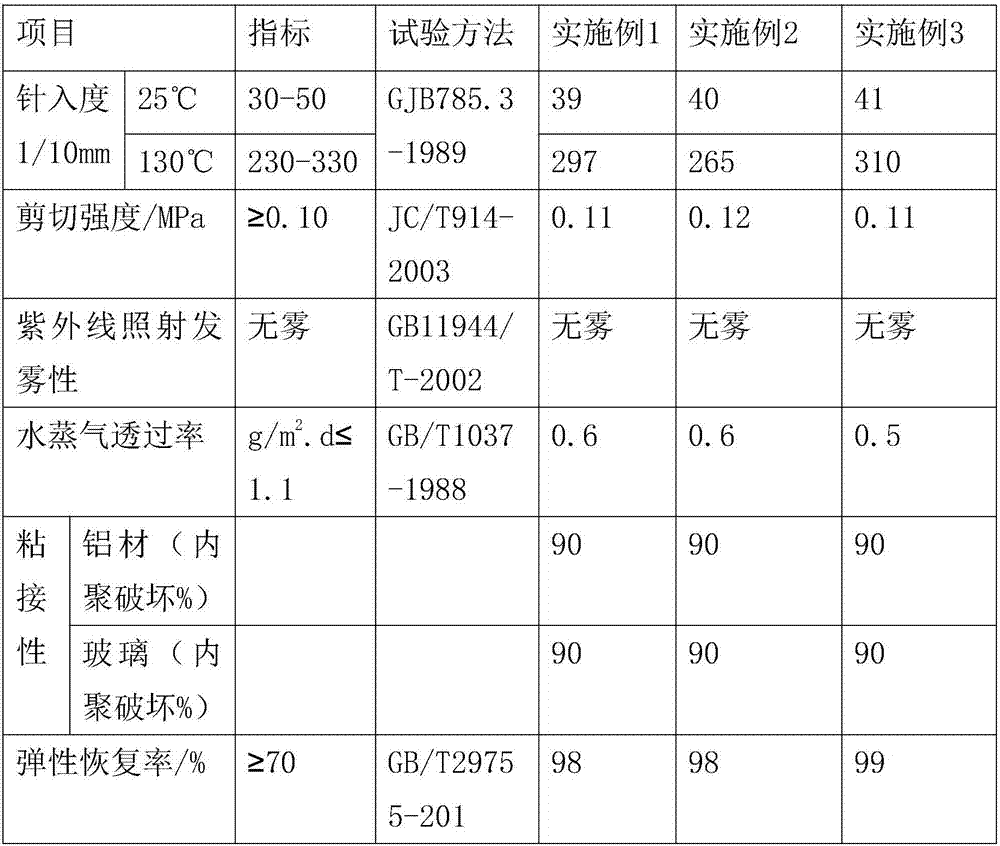

Examples

Embodiment 1

[0027] An outer sealant for insulating glass, comprising the following components in parts by mass: 30 parts of modified butyl rubber, 20 parts of silicone rubber, 35 parts of polyisobutylene, 10 parts of polyvinyl alcohol, 15 parts of borax, and adhesive 2 parts, 1 part of plasticizer, 2 parts of colorant;

[0028] The modified butyl rubber includes butyl rubber, polysulfide rubber in 15 parts by mass, EPDM rubber in 15 parts by mass and tetrahydrofuran in 800 parts by mass;

[0029] The adhesive is a mixture of polyvinylpyrrolidone and vinyl chloride copolymer resin;

[0030] The plasticizer is dioctyl phthalate.

[0031] The preparation method of described modified butyl rubber is:

[0032] 1) Dissolving butyl rubber and polysulfide rubber in a tetrahydrofuran solvent 10-20 times the total mass, raising the temperature to 80-120°C, stirring magnetically for 1-2 hours, standing and cooling to room temperature to obtain spare material a;

[0033] 2) Dissolve EPDM rubber in...

Embodiment 2

[0040] An outer sealant for insulating glass, comprising the following components in parts by mass: 50 parts of modified butyl rubber, 25 parts of silicone rubber, 45 parts of polyisobutylene, 20 parts of polyvinyl alcohol, 25 parts of borax, and adhesive 12 parts, 4 parts of plasticizer, 3 parts of colorant;

[0041] The modified butyl rubber includes 40 parts by mass of butyl rubber, 20 parts by mass of polysulfide rubber, 20 parts by mass of EPDM rubber and 1000 parts by mass of tetrahydrofuran;

[0042] The adhesive is a mixture of chlorinated rubber and epoxy resin;

[0043] Described plasticizer is the mixture of dipentaerythritol ester and chlorinated paraffin;

[0044] The molecular weight of the polyisobutylene is greater than 50,000.

[0045] The preparation method of described modified butyl rubber is:

[0046] 1) Dissolving butyl rubber and polysulfide rubber in a tetrahydrofuran solvent 10-20 times the total mass, raising the temperature to 80-120°C, stirring m...

Embodiment 3

[0054] An outer sealant for insulating glass, comprising the following components in parts by mass: 40 parts of modified butyl rubber, 22 parts of silicone rubber, 40 parts of polyisobutylene, 15 parts of polyvinyl alcohol, 20 parts of borax, and adhesive 8 parts, 2 parts of plasticizer, 2.5 parts of colorant;

[0055] The modified butyl rubber includes 35 parts by mass of butyl rubber, 18 parts by mass of polysulfide rubber, 18 parts by mass of EPDM rubber and 900 parts by mass of tetrahydrofuran;

[0056] The adhesive is a mixture of vinyl acetate copolymer resin, chlorinated rubber and epoxy resin;

[0057] The plasticizer is a mixture of diisodecyl adipate, dipentaerythritol ester and chlorinated paraffin.

[0058] The preparation method of described modified butyl rubber is:

[0059] 1) Dissolving butyl rubber and polysulfide rubber in a tetrahydrofuran solvent 10-20 times the total mass, raising the temperature to 80-120°C, stirring magnetically for 1-2 hours, standing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com