Preparation of WO3/ZrO2 nano microparticle catalyst supported on gamma-Al2O3

A nanoparticle and catalyst technology, applied in the field of chemistry, can solve problems such as limitations and small acid content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

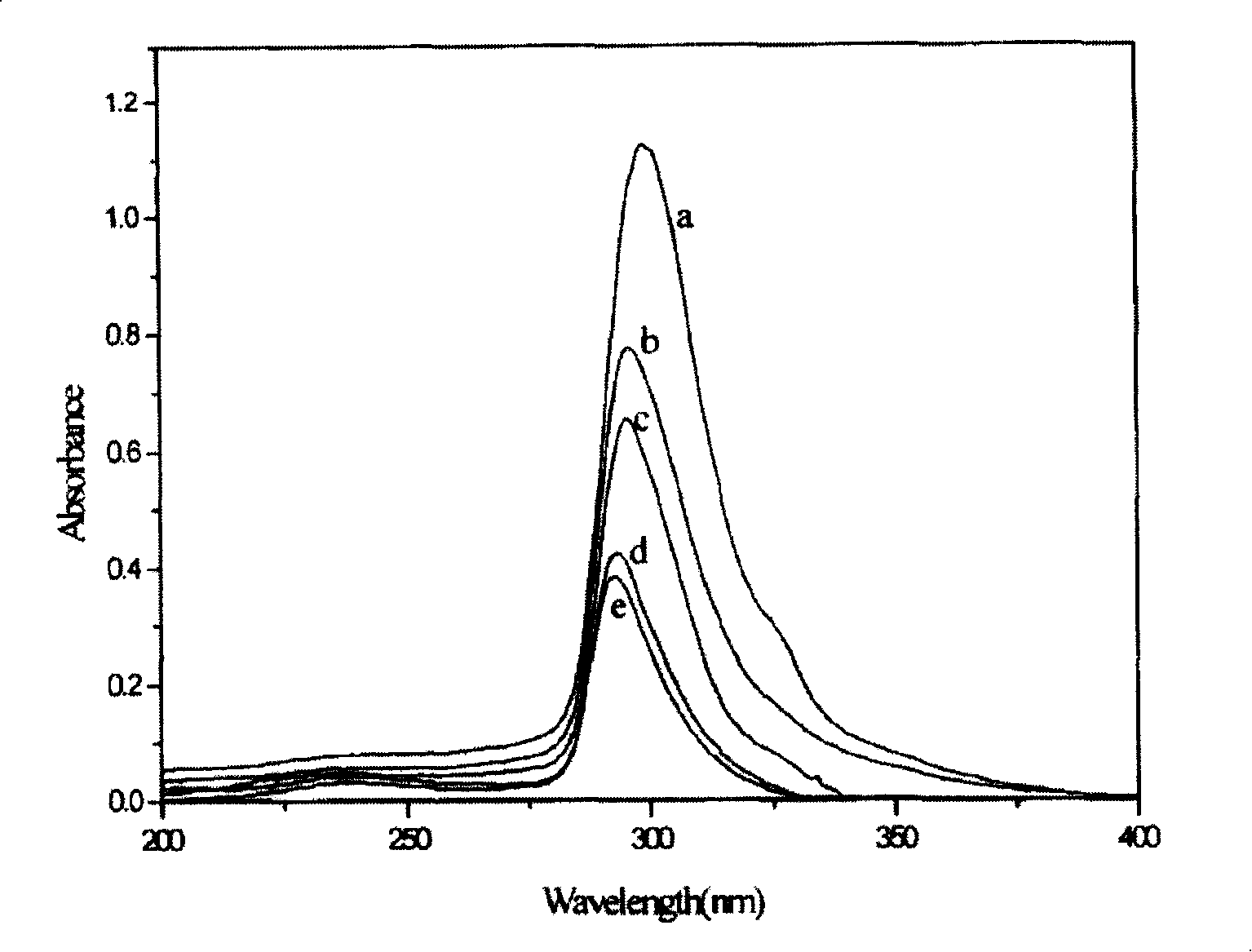

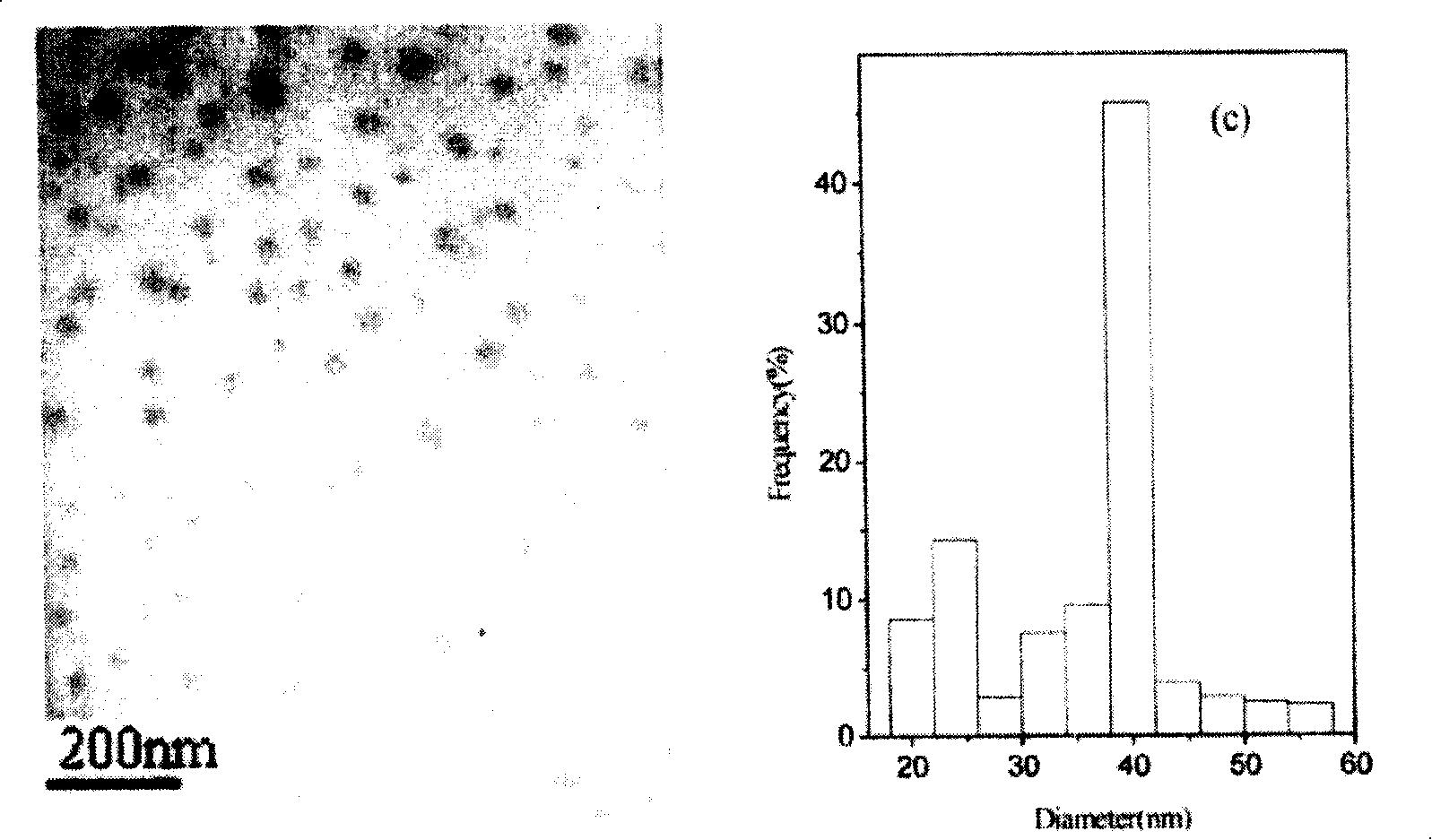

[0040] Prepare the AOT / iso-octane solution of 0.1mol / L, add the aqueous solution (0.01mol / L) of 0.045mLNaOH in the 5mLAOT / iso-octane solution, have obtained the reverse micelle solution of NaOH; Add 0.039mL ZrOCl to the alkane solution 2 (0.01mol / L) and 0.006mL SiO 2 ·12WO 3 26H 2 A mixed aqueous solution of O (0.01mol / L) was stirred at room temperature for 30 minutes until the system was transparent and clear, and SiO 2 ·12WO 3 26H 2 O and ZrOCl 2 Mix the reverse micellar solution; add the reverse micellar solution of NaOH to SiO dropwise using a dropping funnel 2 ·12WO 3 26H 2 O and ZrOCl 2 Mix the reverse micelles solution, cool with an ice-water bath, drop it within 90 minutes, and continue to stir for 22 hours to complete the reaction and obtain WO 3 / ZrO 2 Nanoparticles;

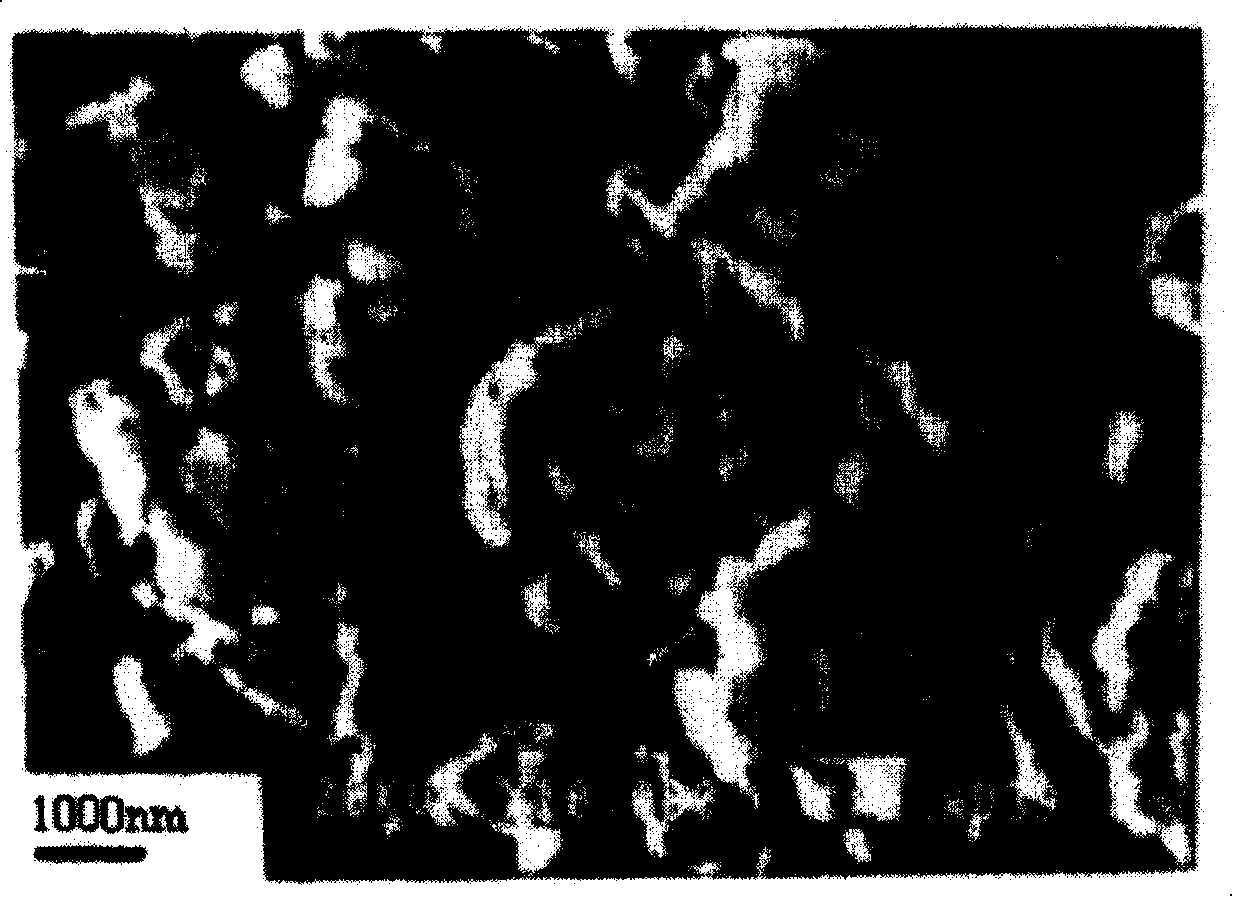

[0041] 10 ml of WO 3 / ZrO 2 Add 2 g of γ-Al to the reverse micellar solution of nanoparticles 2 o 3 (100 mesh), magnetically stirred for 24 hours, and filtered to obtain 2 o 3 WO on ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com