Colorful steel plate inert gas circulating heating curing method and equipment thereby

An inert gas, circulating heating technology, which is used in devices for coating liquid on the surface, chemical variable control, and multiple fluid ratio control. It can solve problems such as excessive energy consumption and environmental protection, and reduce emissions and air supply. The effect of reducing and reducing power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The specific implementation manner of the present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

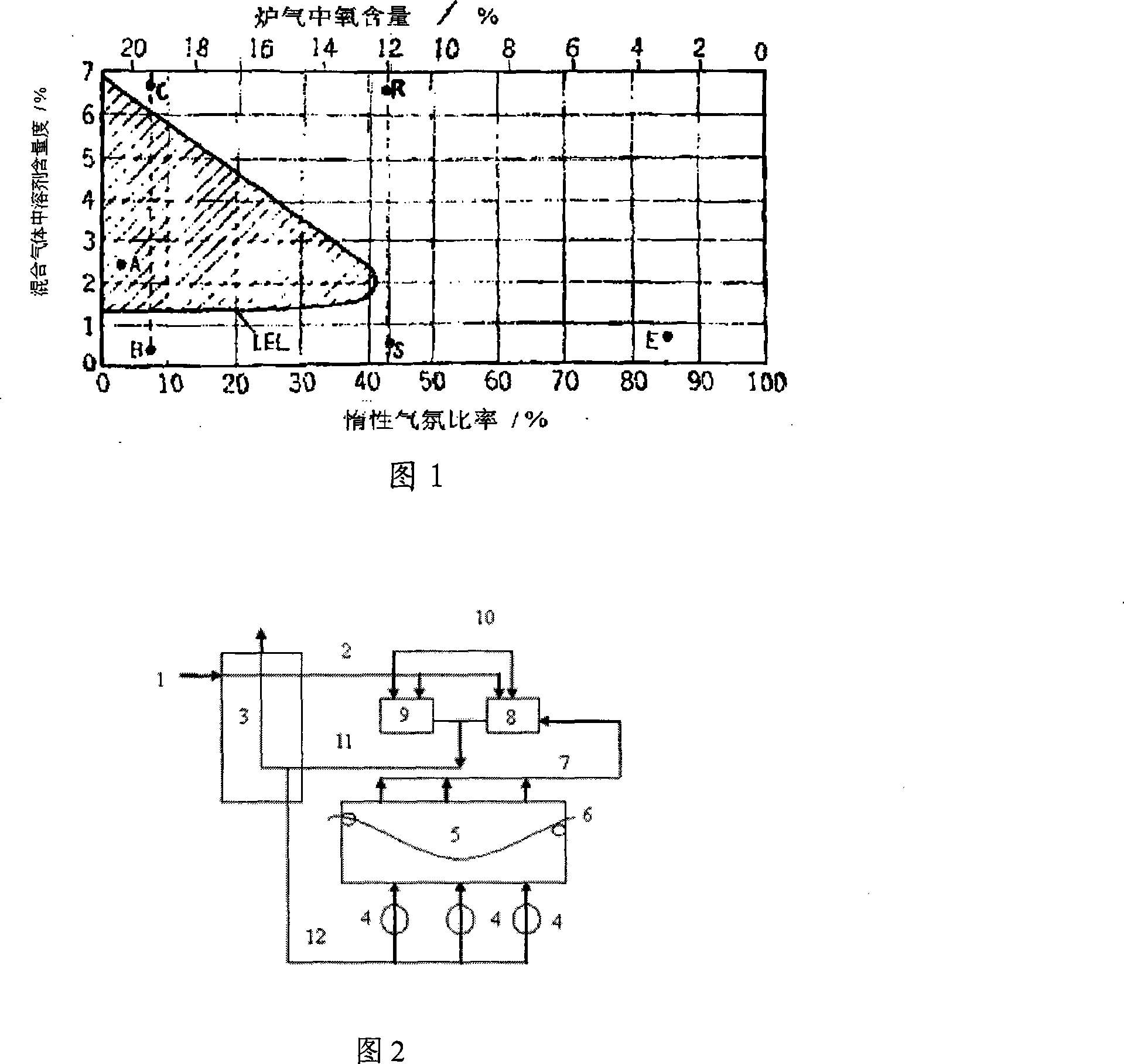

[0036] According to the method for heating and curing color steel plate inert gas circulation of the present invention, the heating and curing of the coating is carried out in two sectional temperature-controlled hot-air paint curing furnaces, and the flue gas after fuel combustion is sent into four sections or divided into four sections or The paint curing furnace with a five-stage structure heats the steel plate coated with liquid organic paint. When the hot air circulates in the paint curing furnace to heat the steel plate, the organic solvent in the paint gradually volatilizes and the paint is cured. It is characterized in that by controlling the combustion furnace Compared with the gas ratio of the incinerator, the oxygen content in the exhaust gas is controlled below 12%, and the following new technolo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com