Light degradation of polyvinyl chloride resin

A technology of polyvinyl chloride resin and polyvinyl chloride, which is applied in the field of modified polyvinyl chloride resin, and can solve the problems of plastic products’ applicability, poor light transmittance, and unsatisfactory photocatalytic degradation effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0012] (1) Modified TiO 2 Preparation of nanopowder:

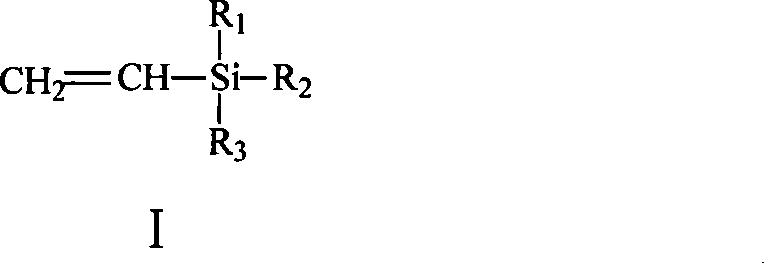

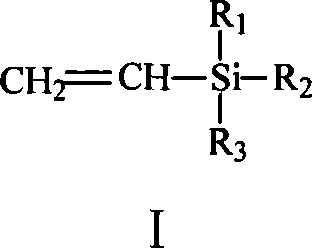

[0013] Titanium dioxide (TiO 2 ) nanoparticles (TiO 2 Particle size is less than 100nm) uniformly dispersed in water or organic solvent, then add silane coupling agent (compound shown in formula I), the addition of silane coupling agent is TiO 2 1% to 20% of the weight of nanoparticles, stirred at 5°C to 80°C for 1 to 24 hours, filtered to obtain modified nano TiO 2 ;

[0014] Wherein said organic solvent is C 1 ~C 6 Aliphatic monohydric alcohol (such as methanol, ethanol, propanol, isopropanol or butanol, etc.), N,N-dimethylformamide (DMF), dimethyl sulfoxide (DMSO), hexane, cyclohexane, toluene or xylene.

[0015] (2) Preparation of the target object:

[0016] Polyvinyl chloride (raw material) with a degree of polymerization of 1700 to 2500 is dissolved in tetrahydrofuran, and then the modified nano-TiO prepared by step (1) is added 2 , modified nano-TiO 2 The weight ratio with polyvinyl chloride (raw material)...

Embodiment 1

[0021] Commercially available P25 nanometer TiO 2 Put it in a container filled with deionized water, add vinyl tris (2-methoxyethoxy) silane (Z-6172) as a modifier after fully dispersing, and control the amount of TiO 2 1% of the added amount, stirred at 20°C for 12 hours, filtered, and dried to obtain modified TiO 2 solid powder. Add 2.0 grams of polyvinyl chloride plastic particles to 60 milliliters of tetrahydrofuran and stir until fully dissolved; then add 0.1 grams of modified TiO2 to the solution 2 Nano-powder, after stirring for 8 hours, tetrahydrofuran was allowed to volatilize naturally at room temperature to obtain photocatalytic self-decomposing polyvinyl chloride plastics, in which TiO 2 The weight percent content of the photocatalyst is 5.0%. The light transmittance and photocatalytic self-decomposition effect of photocatalytic self-decomposition polyvinyl chloride plastic were tested, and the results are shown in Table 1.

Embodiment 2

[0023] Commercially available P25 nanometer TiO 2 Put it in a container filled with ethanol, add vinyl tris (2-methoxyethoxy) silane (Z-6172) as a modifier after fully dispersing, and control the amount of TiO 2 5% of the added amount, stirred at 5°C for 24 hours, filtered, and dried to obtain modified TiO 2 solid powder. Add 2.0 grams of polyvinyl chloride plastic particles to 60 milliliters of tetrahydrofuran, stir until fully dissolved; then add 0.04 grams of modified TiO2 to the solution 2 Nano-powder, after stirring for 1 hour, air-dry THF at 80°C to obtain photocatalytic self-decomposing polyvinyl chloride plastic, in which TiO 2 The weight percent content of the photocatalyst is 2.0%. The light transmittance and photocatalytic self-decomposition effect of photocatalytic self-decomposition polyvinyl chloride plastic were tested, and the results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com