Kitchen garbage drying device and method

A food waste drying technology, applied in drying, drying machines, non-progressive drying machines, etc., can solve the problems of small heat transfer area, heat transfer medium is easy to stick to waste, and high processing costs, achieving obvious Economic benefits, fast and effective drying treatment, and large processing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

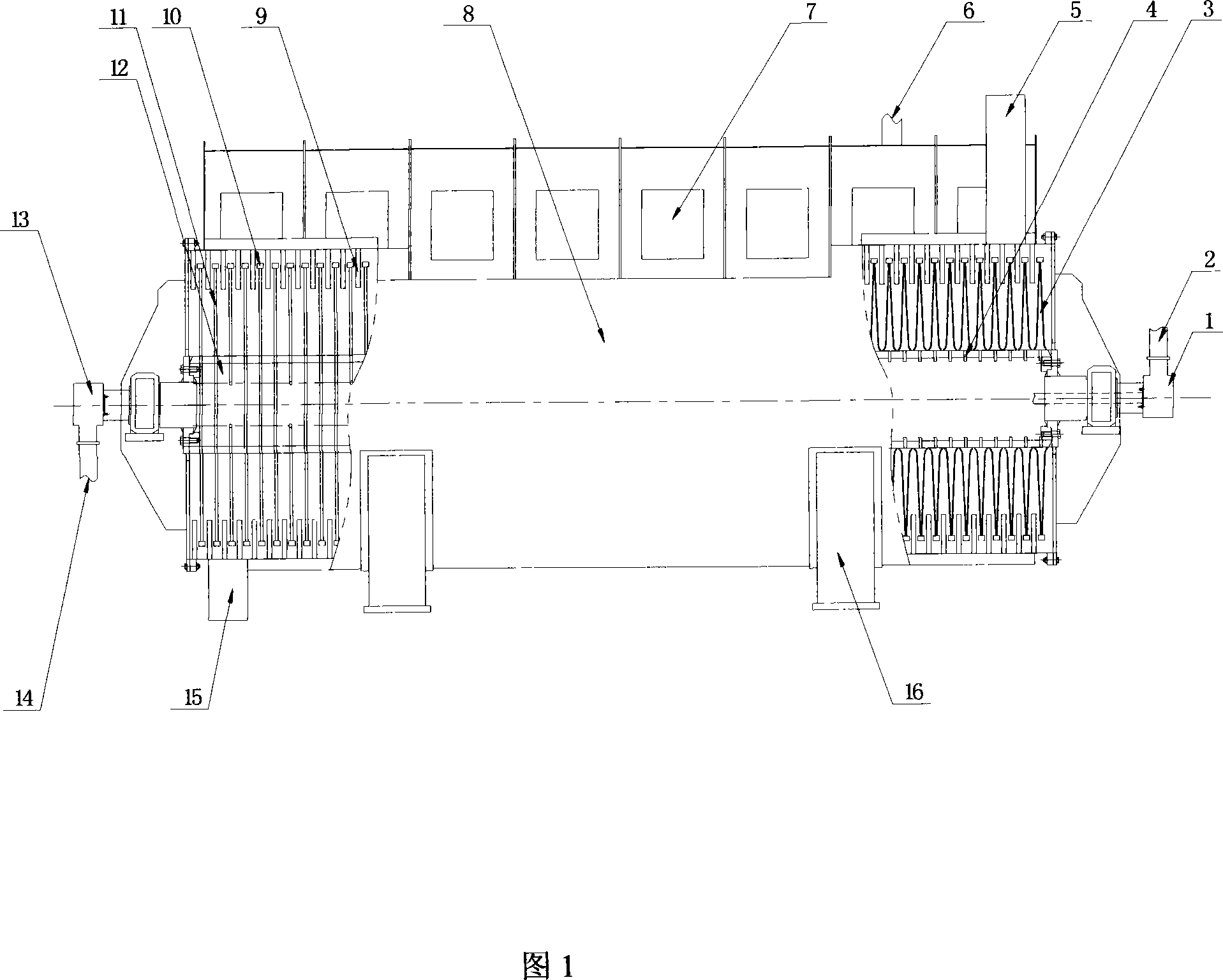

[0027]The device comprises a cylindrical shell (8) fixed on a support base (16), a feed inlet (5) is provided at the upper part of the front end of the housing and a discharge port (15) is provided at the lower part of the rear end, and 30- Scraper (9) with an inclination angle of 60°; a hollow shaft (12) is located at the axis of the cylindrical shell, and the front end of the shaft is equipped with a high-temperature heat-conducting medium introduction pipe (2), and the heat-conducting medium is introduced into the rotary joint (1) through the introduction pipe into the cavity of the hollow shaft, and enter the cavity of the hollow disk (3) and coil tube (11) fixed on the hollow shaft through the catheter (4) arranged on the hollow shaft; the introduction tube and the hollow shaft can pass through 360°rotating import rotary joint connection; cavity disk and coil tube are installed on the hollow shaft along the feeding direction; stirring blades (10) with an inclination angle ...

Embodiment 2

[0029] The drying method of kitchen waste: the high-temperature heat-conducting medium enters the cavity of the hollow shaft through the importing rotary joint through the introduction pipe, and enters the cavity of the hollow disk and the coil tube fixed on the hollow shaft through the conduit arranged on the hollow shaft , so that the cavity of the hollow shaft, the hollow disk and the coil is filled with a high-temperature heat-conducting medium and is evenly heated. The hollow shaft is connected to the motor to get power to rotate, so the hollow disc and the coil also rotate. At this time, the food waste containing a large amount of water enters the device from the feed port, and is indirectly heated by the hollow shaft, the hollow disc and the coil to make the food waste dry. Bacteria and pathogenic bacteria are killed by high temperature. Stirring blades are arranged on the hollow disc and the coil tube, and scrapers are arranged on the inner wall of the device, so that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com