Surface enhanced raman scattering activity nanometer porous metal substrate and method for making same

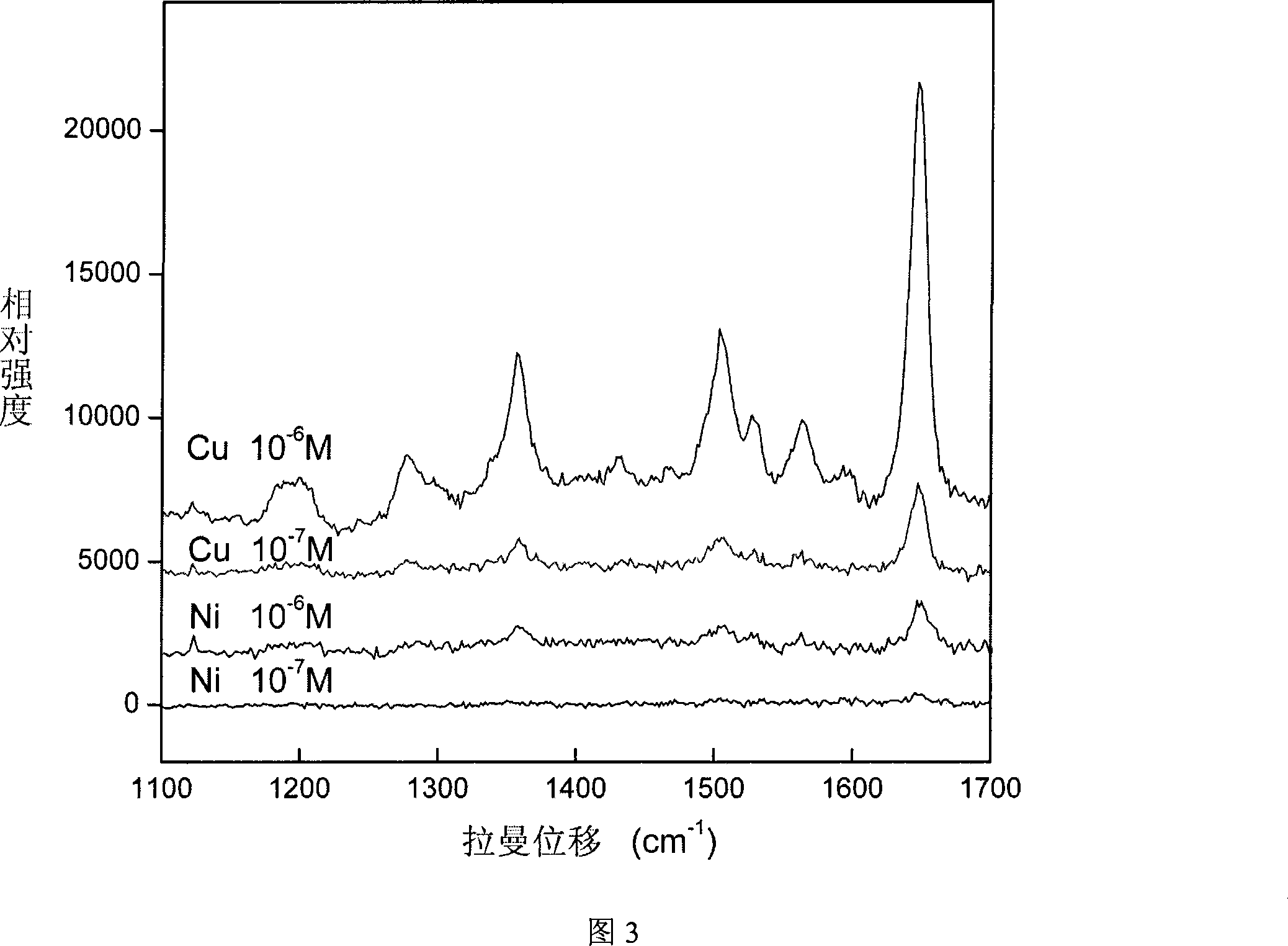

A surface-enhanced Raman and nanoporous technology, used in Raman scattering, material excitation analysis, etc., can solve the problems of signal reproducibility, poor stability, short storage time, and complicated preparation, and achieve good substrate stability and cost. Low, reproducible effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The preparation method of the nanoporous metal copper substrate with surface-enhanced Raman scattering activity proposed by the present invention comprises the following steps:

[0028] (1) Ultrasonic dispersion of spherical nickel phosphate colloidal particles prepared by a uniform precipitation method in absolute ethanol to obtain a stable suspension.

[0029] (2) Put a conductive substrate (such as a silicon wafer sputtered with Pt on the surface) into the above-mentioned colloidal particle suspension as the cathode, use a graphite electrode as the anode, apply a 20-30V DC voltage between the electrodes, and electrophoretically deposit it on the cathode substrate. Obtain a uniformly coated colloidal deposition film; or place a conductive substrate (such as a silicon wafer sputtered with Pt on the surface) obliquely into the above-mentioned colloidal particle suspension, the conductive surface and the liquid surface form an angle of 40-50 degrees, at 60 ° C The solven...

Embodiment 1

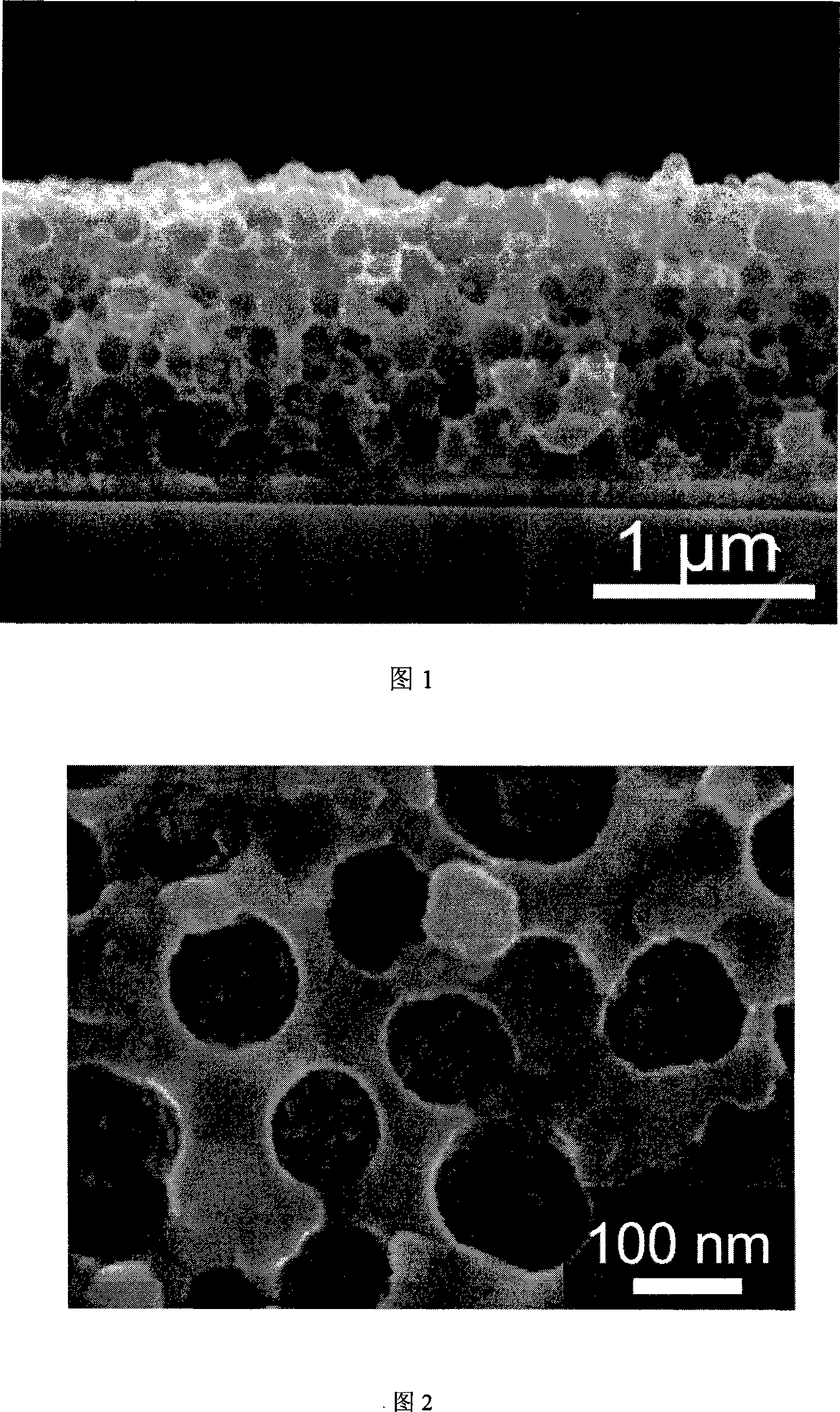

[0040] (1) Ultrasonic dispersion of spherical nickel phosphate colloid particles with a diameter of 100±30 nm prepared by a uniform precipitation method in absolute ethanol to obtain a stable suspension.

[0041](2) Put the silicon chip sputtered with Pt on the surface into the above-mentioned colloidal particle suspension as the cathode, use the graphite electrode as the anode, apply a 20V DC voltage between the electrodes, energize for 10 minutes, and obtain a uniform coating by electrophoretic deposition on the cathode substrate colloidal deposition film.

[0042] (3) Dry the above-mentioned colloidal deposition film together with the substrate, put it into a heating furnace, and heat-treat it in air at 200° C. for 2 hours to obtain a template layer on the conductive substrate.

[0043] (4) Put the above-mentioned template together with the substrate into the metal electroplating solution as the cathode, the electroplating solution is a citric acid-tartaric acid copper plat...

Embodiment 2

[0046] (1) Ultrasonic dispersion of spherical nickel phosphate colloid particles with a diameter of 150±50 nm prepared by a uniform precipitation method in absolute ethanol to obtain a stable suspension.

[0047] (2) Put the silicon chip sputtered with Pt on the surface into the above-mentioned colloidal particle suspension as the cathode, use the graphite electrode as the anode, apply a 30V DC voltage between the electrodes, and electrophoretically deposit it on the cathode substrate for 5 minutes to obtain a uniform coating. Colloidal deposition film.

[0048] (3) Dry the above-mentioned colloidal deposited film together with the substrate, put it into a heating furnace, and heat-treat it in air at 250° C. for 1 hour to obtain a template layer on the conductive substrate.

[0049] (4) Put the above-mentioned template together with the substrate into the metal electroplating solution as the cathode, the electroplating solution is a citric acid-tartaric acid copper plating sol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com