Micro-electrolysis device for aeration fluidized bed

A fluidized bed and micro-electrolysis technology, applied in the direction of electrochemical water/sewage treatment, can solve the problems of large power consumption and easy loss of packing, and achieve the effect of reducing operating costs, avoiding packing loss, and reducing electricity consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

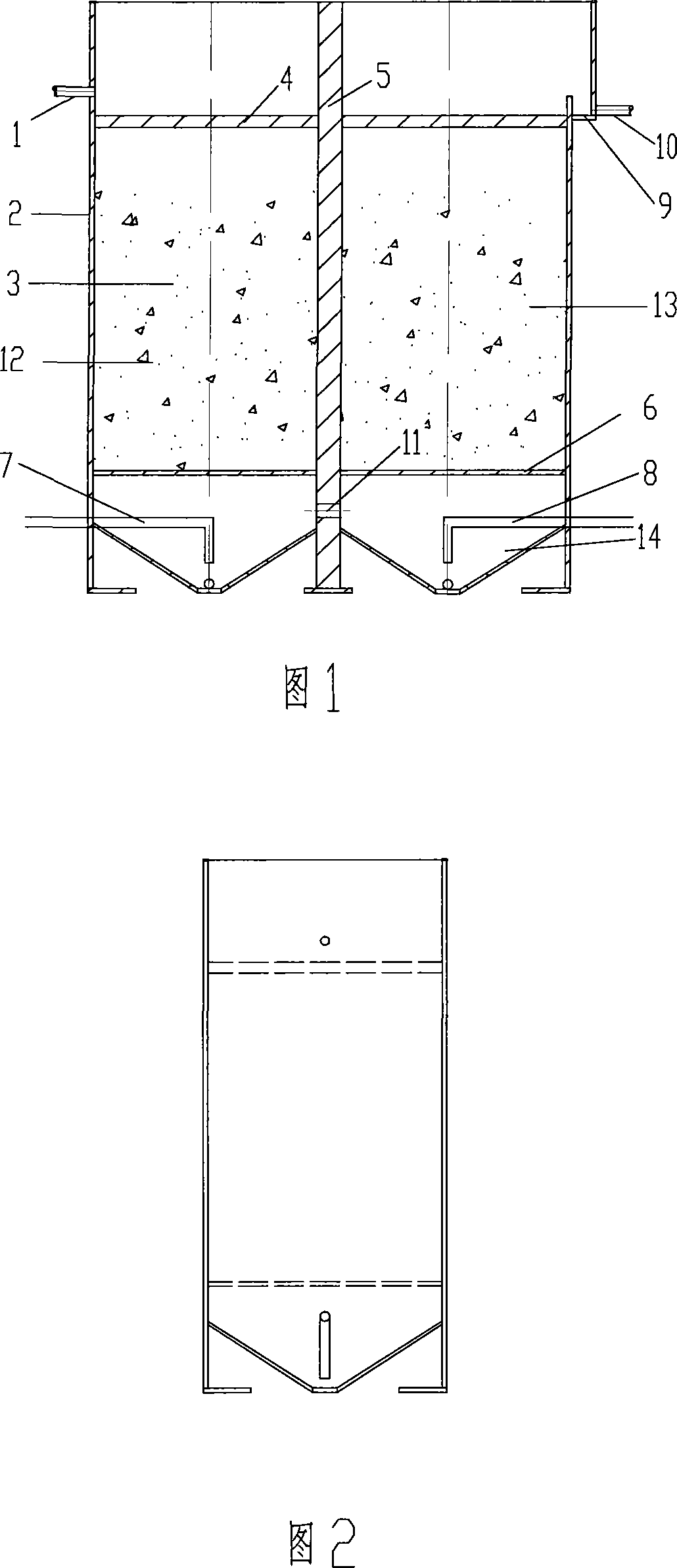

Embodiment 1

[0018] Put LXFC series iron-carbon filler in the micro-electrolysis device with a height of 1.25 meters made of PVC material, and introduce a certain benzene-containing organic wastewater into the water inlet pipe 1 of the aeration fluidized bed micro-electrolysis device. Waste water quality: COD Cr =1000-1500mg / L, PH=6-7, BOD / CODCr Cr =0.50, the organic matter is degraded obviously, and the biodegradability of the waste water is improved.

Embodiment 2

[0020] The device in Example 1 is used to treat printing and dyeing wastewater, and the wastewater is introduced into the water inlet pipe 1 of the aeration fluidized bed micro-electrolysis device, and the wastewater passes through the grid 4 through the filler 3, and an electrochemical reaction occurs, accompanied by reduction degradation and coagulation, etc. physical and chemical phenomena. The aeration tube 7 is used to continuously impact the bucket bottom of the first chamber 12, and the second chamber is not aerated, so that the filling in the first chamber is in a fluidized state and reacts. The water after the reaction in the first chamber 12 enters the second chamber 13 through the hole 11 at the bottom of the partition plate 5, and further micro-electrolysis reaction occurs. The reacted water passes through the outlet weir 9 and is discharged from the outlet pipe 10. The COD of the wastewater Cr 800-1500mg / L, PH=8-11, chromaticity 264-1100 (dilution factor), after b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com