Method for producing titanium dioxide coating capillary column with liquid deposition method

A titanium dioxide, liquid phase deposition technology, applied in the field of preparation of titanium dioxide coated capillary column, can solve the problems of poor repeatability, complicated preparation steps, and insufficient understanding of capillary separation and analysis applications, and achieve the effect of low cost and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

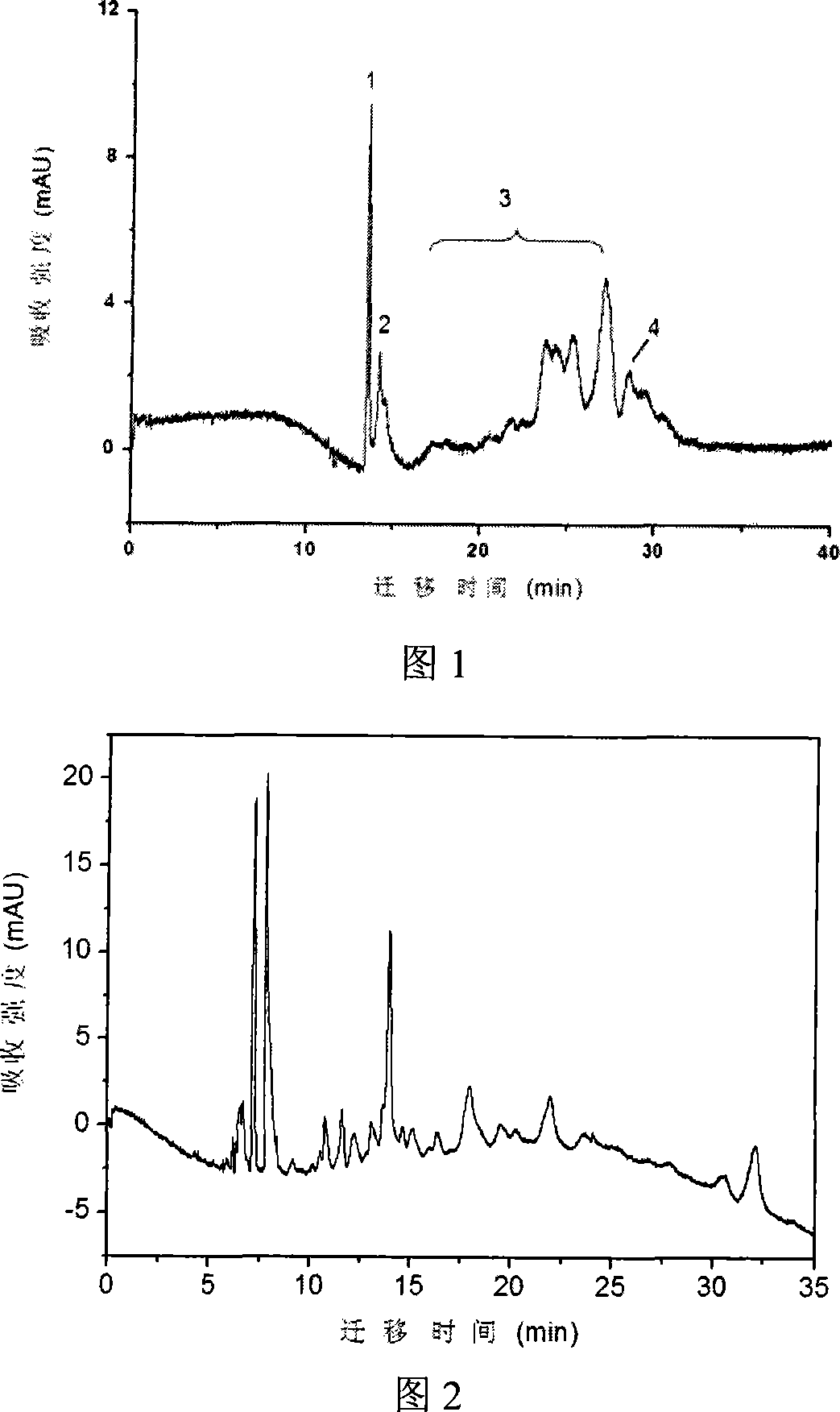

[0015] Preparation of titania-coated capillary columns:

[0016] (1) Activation of the capillary: the quartz capillary is washed with 1M sodium hydroxide for 2-4 hours, water for 0.5-1 hour, 1M hydrochloric acid for 4-8 hours, H 2 Rinse with O for 0.5-1 hour, then dry with nitrogen at 120-160°C for later use.

[0017] (2) Preparation of titanium dioxide-coated capillary column: Mix 0.2M ammonium fluotitanate and 0.6M boric acid in equal volumes, then inject into the activated capillary, seal both ends of the capillary with silicone rubber, and place in a constant temperature water bath at 35±1°C Deposit in medium for 16-24 hours, blow out the reaction solution, wash with water and dry with nitrogen at 120°C. Subsequently, the capillary was washed sequentially with 0.1 M NaOH and deionized water. Afterwards, the capillary with deposited titanium dioxide film was placed in a muffle furnace, the temperature was programmed to 300°C at a rate of 1°C / min, and kept at 300°C for 2 h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com