Production method for diamin type high fire-retardancy benzoxazine resin containing phosphor

A benzoxazine and diamine-based technology, applied in the field of thermosetting resin preparation, to achieve good flame retardancy, good thermal performance, and high heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

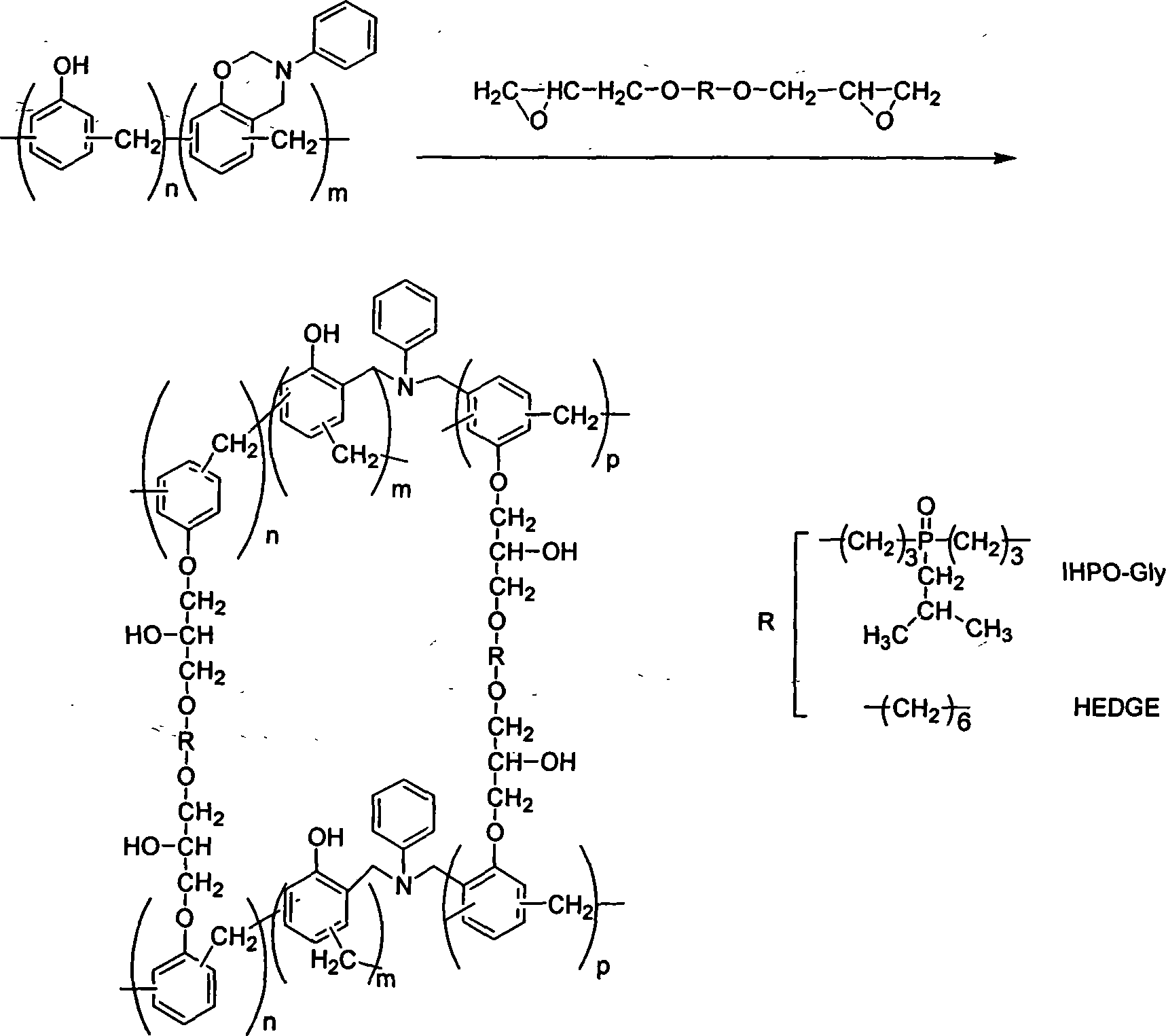

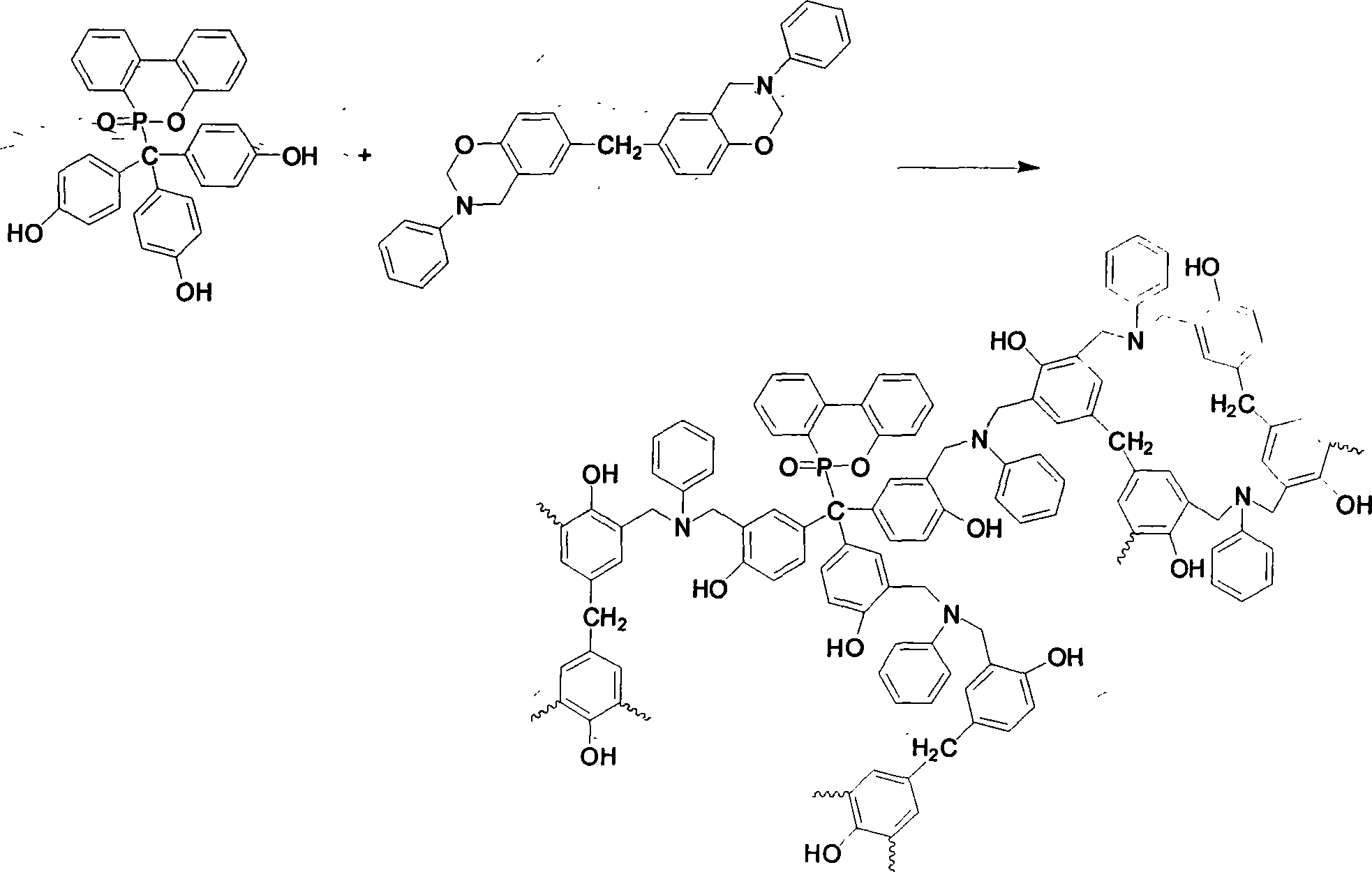

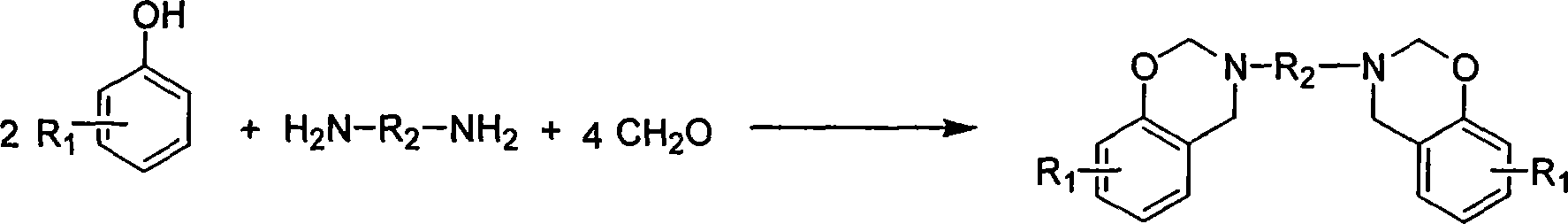

Method used

Image

Examples

Embodiment 1

[0034] Synthesis of 3,3'-phosphophenyl-6-methyl-3,4-dihydro-2H-1,3-benzoxazine resin.

[0035] The preparation process of synthesizing benzoxazine resin with phosphorus-containing diamine: 2 (4-aminophenyl) phenyl phosphate, monohydric phenol: p-cresol and formaldehyde as raw materials:

[0036] Add 75ml of chloroform, 0.7g of triethylamine and 24ml of 35% formaldehyde solution in sequence into a 250ml three-neck flask equipped with a stirrer and a condenser, and stir to mix. Slowly add 25.6g of 2(4-aminophenyl)phenyl phosphate, control the reaction temperature not to exceed 30°C, and adjust the pH value to 7 with triethylamine to generate N-dimethylol compound and keep it stable in the solution ;

[0037] Add 15.5g p-cresol after reacting for 15min, heat up to reflux, stop the reaction after the mixed solution reacts at reflux temperature for 5h, and make N-dimethylol compound and phenolic hydroxyl group and the ortho-position on benzene ring produce condensation reaction, ...

Embodiment 2

[0042] Synthesis of 3,3'-phosphophenyl-5-methyl-3,4-dihydro-2H-1,3-benzoxazine resin.

[0043] The preparation process of synthesizing benzoxazine resin with phosphorus-containing diamine: 2 (4-aminophenyl) phenyl phosphate, monohydric phenol: m-cresol and formaldehyde as raw materials:

[0044] Add 90ml of chloroform, 0.84g of triethylamine and 28.8ml of 36% formaldehyde solution in sequence into a 250ml three-neck flask equipped with a stirrer and a condenser, and stir to mix. Slowly add 30.7g of 2(4-aminophenyl)phenyl phosphate, control the reaction temperature not to exceed 30°C, and adjust the pH value to 7 with triethylamine to generate N-dimethylol compound and keep it stable in the solution ;

[0045] After reacting for 15 minutes, add 18.6 g of m-cresol, raise the temperature to reflux, and stop the reaction after the mixed solution reacts at the reflux temperature for 5 hours, so that the N-dimethylol compound, the phenolic hydroxyl group and the ortho position on t...

Embodiment 3

[0050] Synthesis of 3,3'-Phenyl Phosphate-3,4-Dihydro-2H-1,3-Benzoxazine Resin

[0051] The preparation process of synthesizing benzoxazine resin with phosphorus-containing diamine: 2 (4-aminophenyl) phenyl phosphate, monohydric phenol: phenol and formaldehyde as raw materials:

[0052] Add 75ml of chloroform, 0.7g of triethylamine and 24ml of 37% formaldehyde solution in sequence to a 250ml three-necked flask equipped with a stirrer and a condenser, and stir to mix. Slowly add 25.6g of 2(4-aminophenyl)phenyl phosphate, control the reaction temperature not to exceed 30°C, and adjust the pH value to 7 with triethylamine to generate N-dimethylol compound and keep it stable in the solution ;

[0053] After reacting for 15 minutes, add 13.5g phenol, raise the temperature to reflux, and stop the reaction after reacting the mixed solution at the reflux temperature for 5 hours, so that the N-dimethylol compound and the phenolic hydroxyl group and its ortho position on the benzene ri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap