Oil tube electrical heat quenching and tempering thermal treatment method and apparatus

A technology of quenching and tempering heat treatment and heat treatment method, applied in heat treatment furnaces, heat treatment equipment, heat treatment process control and other directions, can solve the problems of unstable processing quality, large environmental pollution, high energy consumption, and achieve balanced four-phase performance of the tube body, reducing The effect of smoke pollution and uniform temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

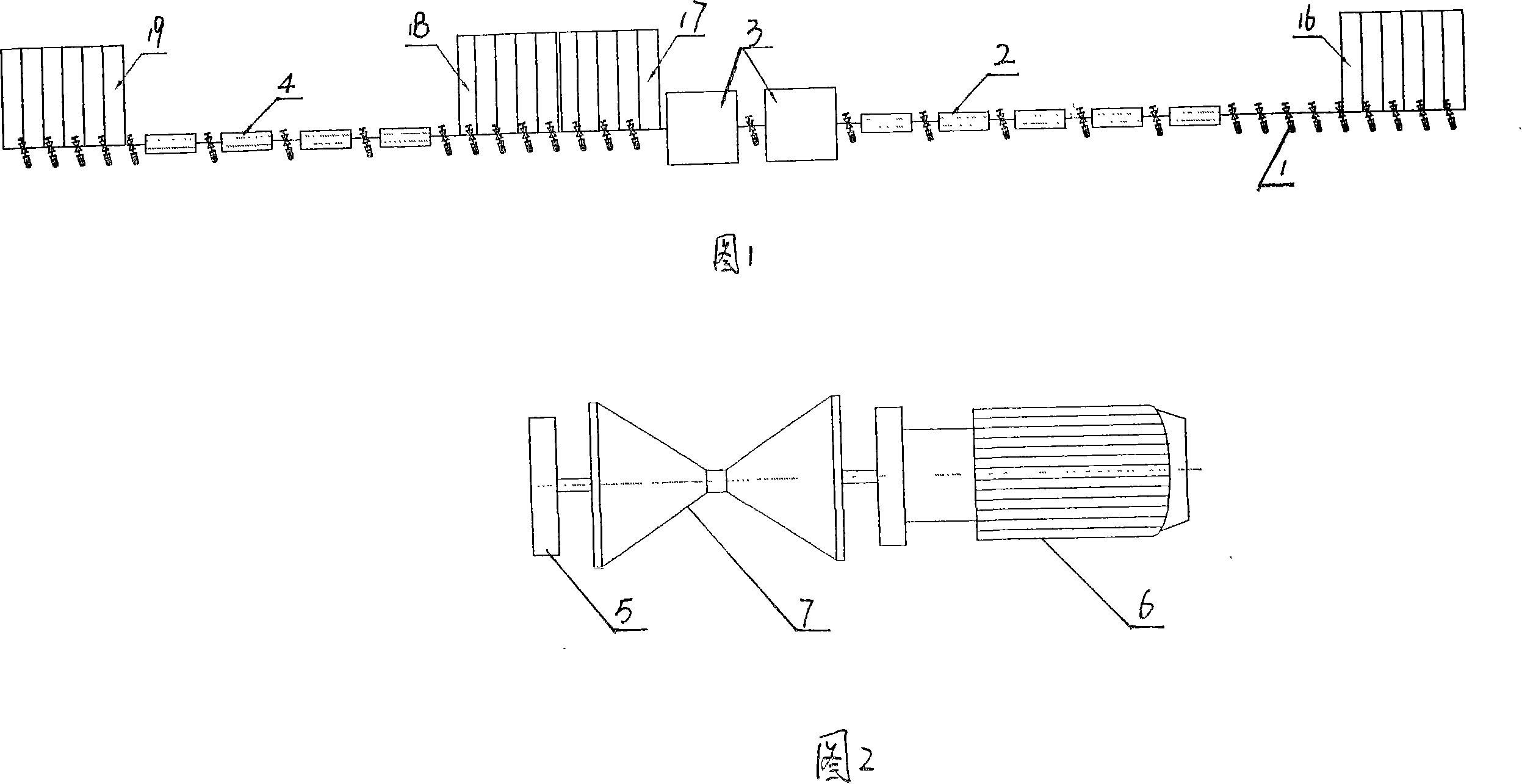

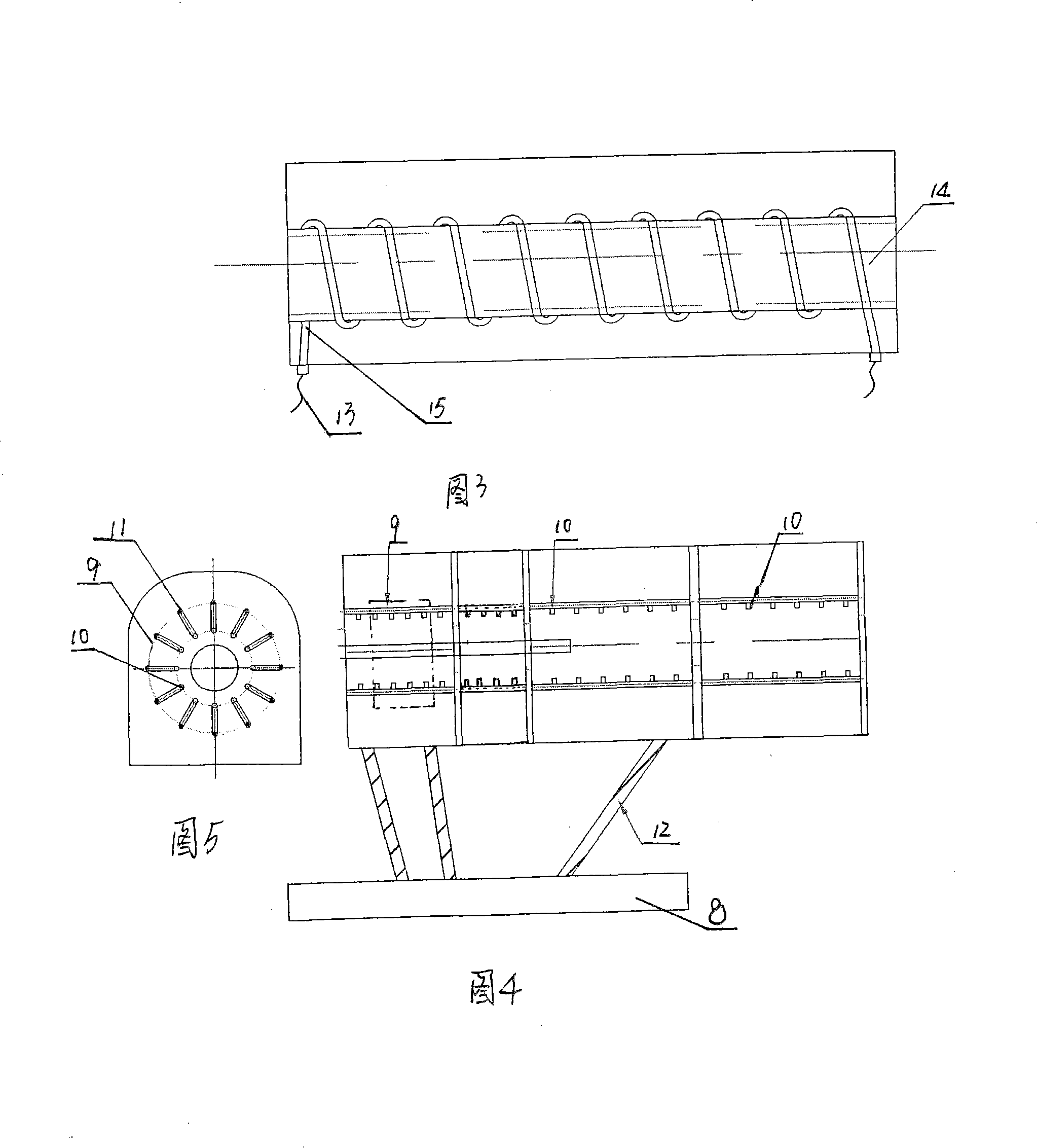

[0022] Example 1: First, the steel pipe is transported from the feeding rack 16 to a set of quenching furnace 2 for heating at a heating temperature of 850°C through the feeder 1; secondly, the heated steel pipe is transported to a set of cooling furnace 3 through the feeder 1 for spray cooling , the water spray pressure is 8MPa, the water flow rate is 500 cubic meters per minute, the spray time is 10 seconds, and the temperature of the steel pipe after spraying is 100°C; then, after spraying, the steel pipe is then cooled by the cooling rack 17, and then cooled by cooling The material rack 18 is transported to a group of tempering furnaces 4 for heating through the feeder 1 at a heating temperature of 500° C.; finally, the tempered steel pipe is transported to the unloading rack 19 through the feeder 1 . The P110 oil casing with a specification of 60.3×4.83mm produced online has a yield strength of 800Mpa and a tensile strength of 890Mpa.

example 2

[0023] Example 2: First, the steel pipe is transported from the feeding rack 16 to a set of quenching furnace 2 for heating at a heating temperature of 925°C; secondly, the heated steel pipe is transported to a set of cooling furnace 3 through the feeder 1 for spray cooling , the water spray pressure is 9MPa, the water flow rate is 500 cubic meters per minute, the spray time is 13 seconds, and the temperature of the steel pipe after spraying is 100°C; then, after spraying, the steel pipe is then cooled by the cooling and unloading rack 17, and then cooled by cooling. The material rack 18 is transported to a group of tempering furnaces 4 for heating through the feeder 1 at a heating temperature of 650° C.; finally, the tempered steel pipe is transported to the unloading rack 19 through the feeder 1 . The P110 oil casing with a specification of 73.02×5.51mm produced online has a yield strength of 815Mpa and a tensile strength of 875Mpa.

example 3

[0024] Example 3: First, the steel pipe is transported from the feeding rack 16 to a group of quenching furnaces 2 for heating at a heating temperature of 1000°C; secondly, the heated steel pipe is transported to a group of cooling furnaces 3 through the feeder 1 for spray cooling , the water spray pressure is 10MPa, the water flow rate is 500 cubic meters per minute, the spray time is 15 seconds, and the steel pipe temperature is 100°C after spraying; The material rack 18 is transported to a group of tempering furnaces 4 for heating through the feeder 1 at a heating temperature of 800° C.; finally, the tempered steel pipe is transported to the unloading rack 19 through the feeder 1 . The C95 oil casing with a specification of 73.02×5.51mm produced online has a yield strength of 710Mpa and a tensile strength of 805Mpa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com