Gas treatment apparatus

A technology of gas treatment and gas injection, which is applied in the fields of electrical components, gaseous chemical plating, semiconductor/solid-state device manufacturing, etc. Occurrence of film formation defects, suppression reduction, and effects of variation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

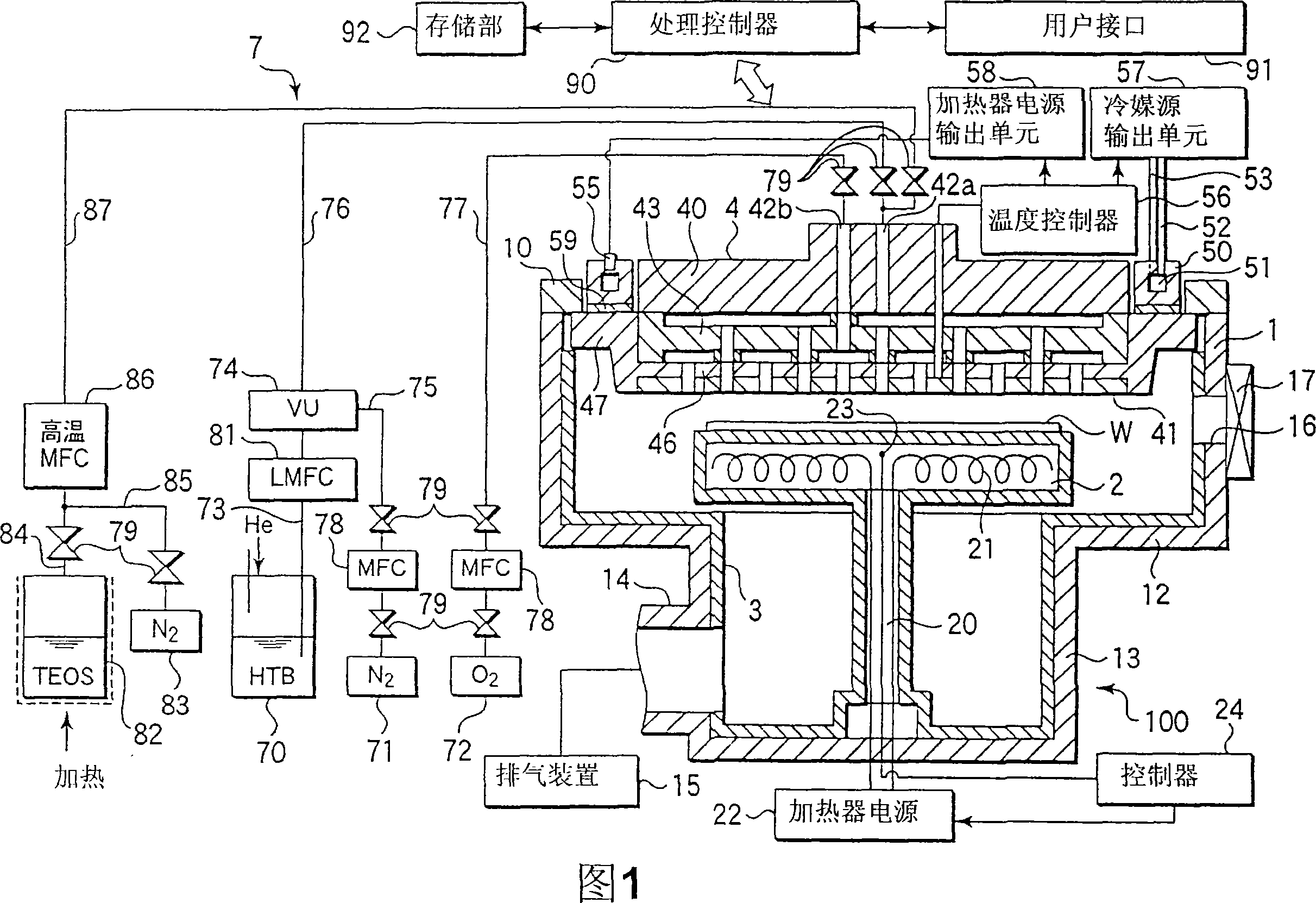

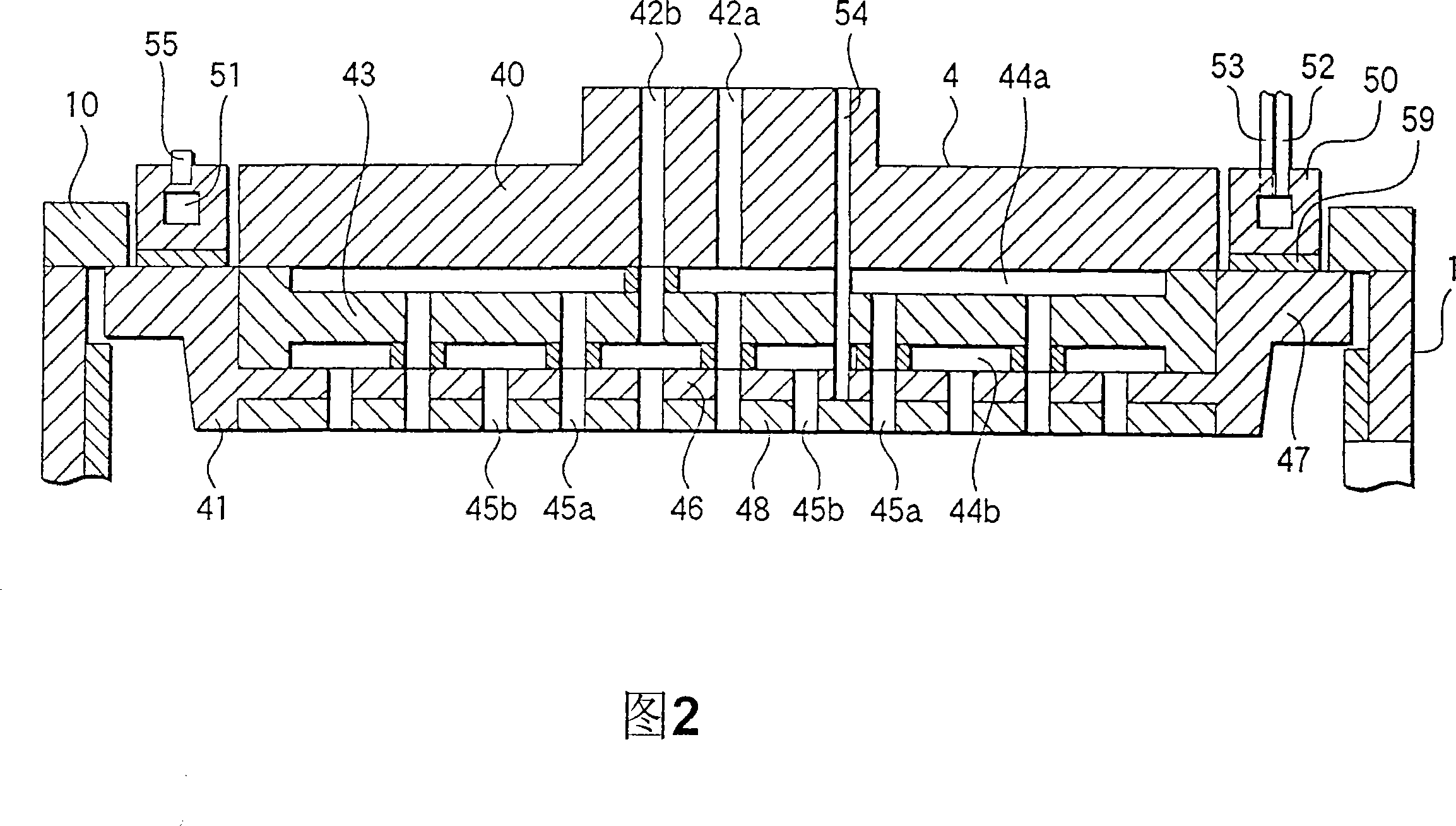

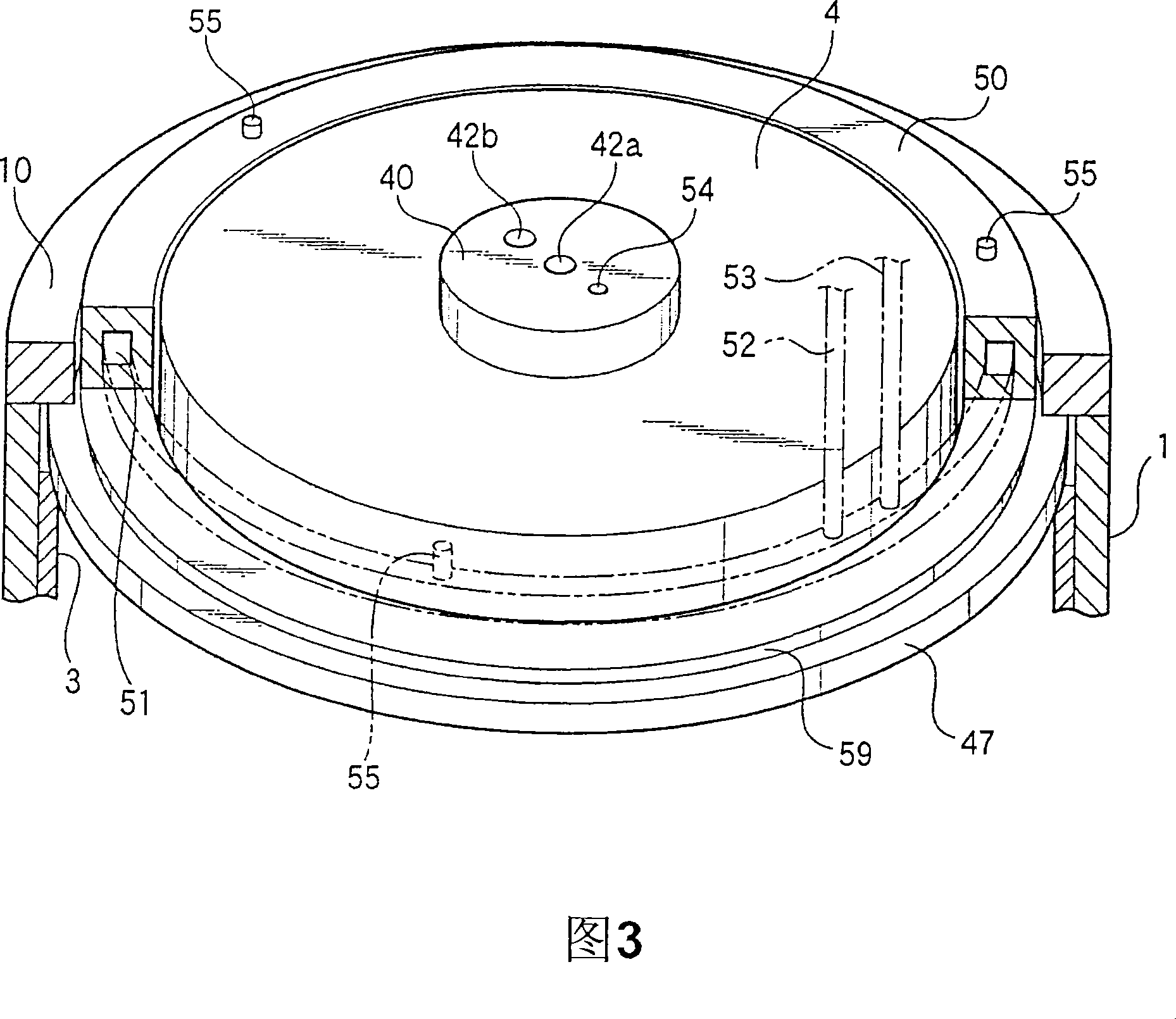

[0028] Embodiments of the present invention will be specifically described below with reference to the drawings.

[0029] 1 is a cross-sectional view showing a film forming apparatus according to an embodiment of the gas processing apparatus of the present invention, FIG. 2 is a cross-sectional view showing a main part of a chamber and a shower head constituting the film forming apparatus, and FIG. 3 is a cross-sectional view showing a chamber and a shower head. A cutaway perspective view of the main part of the nozzle.

[0030]This film forming apparatus 100 has an airtight substantially cylindrical chamber 1 as a processing container, in which a mounting table 2 for horizontally supporting a Si substrate (wafer) W as an object to be processed is arranged so as to pass through the center thereof. It is arranged in a state supported by the lower cylindrical support member 20 . The mounting table 2 is made of ceramics such as AlN. In addition, a heater 21 is embedded in the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com