SiC based composite material component and on-line jointing preparation method thereof

A composite material component and composite material technology, applied in the field of SiC-based composite material components, can solve the problems of reducing the high-temperature service performance of connecting joints, reducing the joint performance of connecting joints, and PCS melting loss, etc., achieving good chemical and mechanical compatibility, The effect of good integrity and guaranteed reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

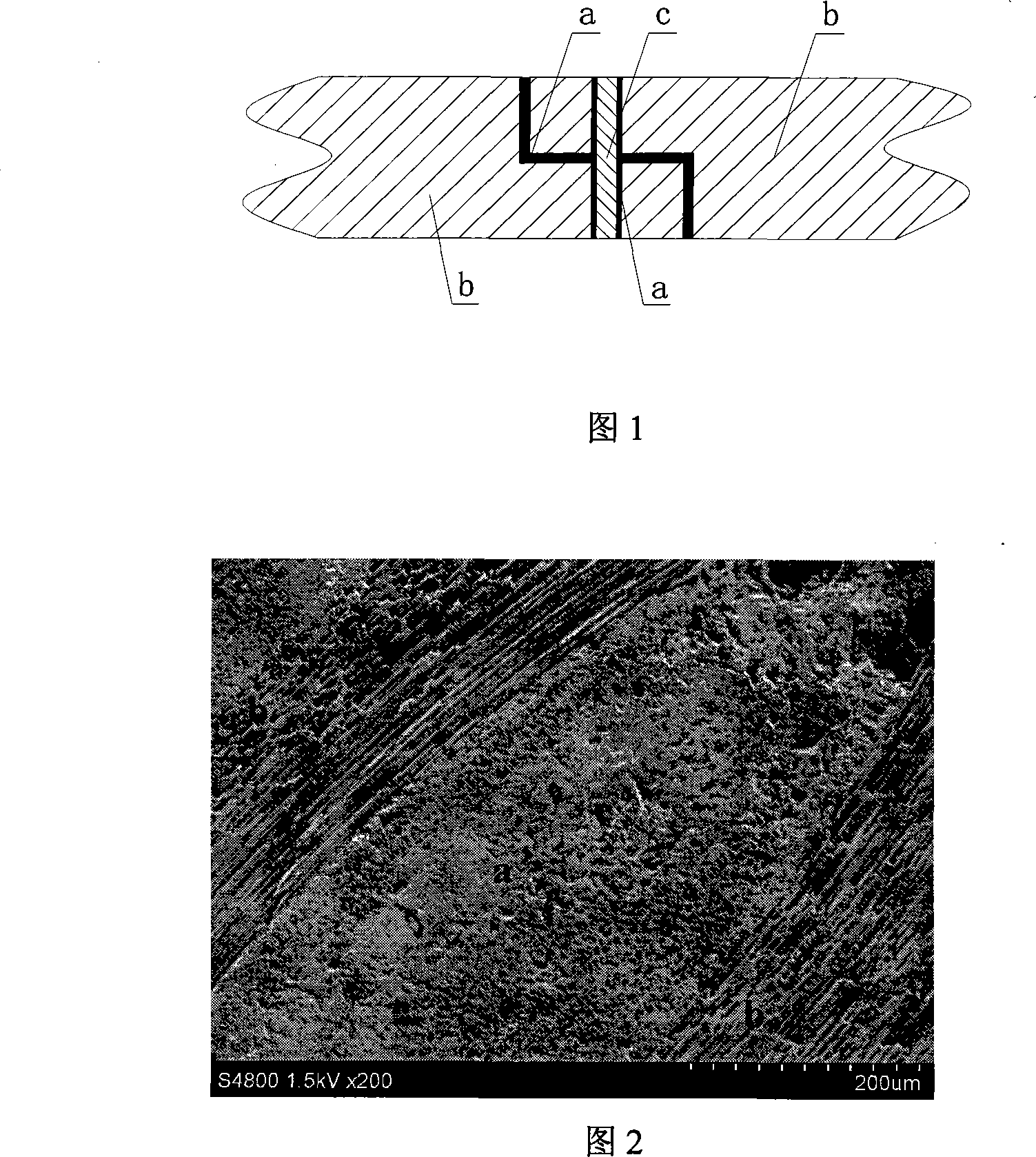

[0023] As shown in Figure 1 and Figure 2, a SiC-based composite material component is formed by connecting the prefabricated SiC-based composite material online by the connector b, the component of the connecting layer a is SiC material, and the two are connected Part b adopts a lap joint structure at the connection joint. There is a pin c connecting the connected part and the connection layer at the connection joint. The diameter of the connection hole of the pin c is Φ5mm. The material is processed. The SiC-based composite material component is prepared by the following method:

[0024] (1) Weave the No. 2 rubber carbon fiber prepared by 6K Jilin Carbon Fiber Factory into a flat plate, vacuum impregnate the mixed solution of PCS / xylene (the mass ratio of PCS to xylene is 1:1), and heat it at 1100 ° C under Ar gas Carry out high-temperature pyrolysis under protection, repeat the impregnation and cracking process for 6 cycles, process the obtained SiC-based composite material...

Embodiment 2

[0030] As shown in Figure 1, a SiC-based composite material component is formed by connecting prefabricated SiC-based composite materials online by a connector b, the component of the connecting layer a is SiC material, and the two connected parts b are in The connecting joint adopts a lap joint structure, and the connecting joint is provided with a pin c connecting the connected part b and the connecting layer a. The diameter of the connecting hole of the pin c is Φ3mm, and the connecting pin c is a one-dimensional SiC / SiC-based composite material processed. The SiC-based composite material component is prepared by the following method:

[0031] (1) Weave Hi-Nicalon SiC fibers into a flat plate, vacuum impregnate PCS in xylene solution (the mass ratio of PCS to xylene is 1:1), and heat it at 1200 °C under N 2 Carry out high-temperature pyrolysis under protection, repeat the impregnation and cracking process for 6 cycles, and process the obtained SiC-based composite material ...

Embodiment 3

[0035] A SiC-based composite material component, which is formed by connecting prefabricated SiC-based composite material connected parts online, the component of the connecting layer is SiC material, and the two connected parts are connected in a wedge-shaped connection at the joint, There is also a pin connecting the connected part and the connecting layer at the connecting joint. The diameter of the connecting hole of the pin is Φ6mm. obtained by densification. The SiC-based composite material component is prepared by the following method:

[0036] (1) Weave T300 carbon fiber into a flat plate, vacuum impregnate PCS in a xylene solution (the mass ratio of PCS to xylene is 1:1), and heat it at 1200 ° C under N 2 Carry out pyrolysis under protection, repeat the impregnation and cracking process for 6 cycles, process the obtained C / SiC composite material into a connected part with a wedge-shaped connection structure, and make the joints of the two connected parts cooperate wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com