Ethyl silicon oil based magnetic liquid and preparation method thereof

A technology of ethyl silicone oil and magnetic liquid, applied in the direction of the solid anode of the discharge tube, the main electrode of the discharge tube, etc., can solve the problems of poor oxidation resistance, poor magnetic properties, poor stability, etc., and achieve low equipment requirements and simple preparation methods , the effect of uniform particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Example 1 Preparation of ethyl silicone oil-based magnetic liquid

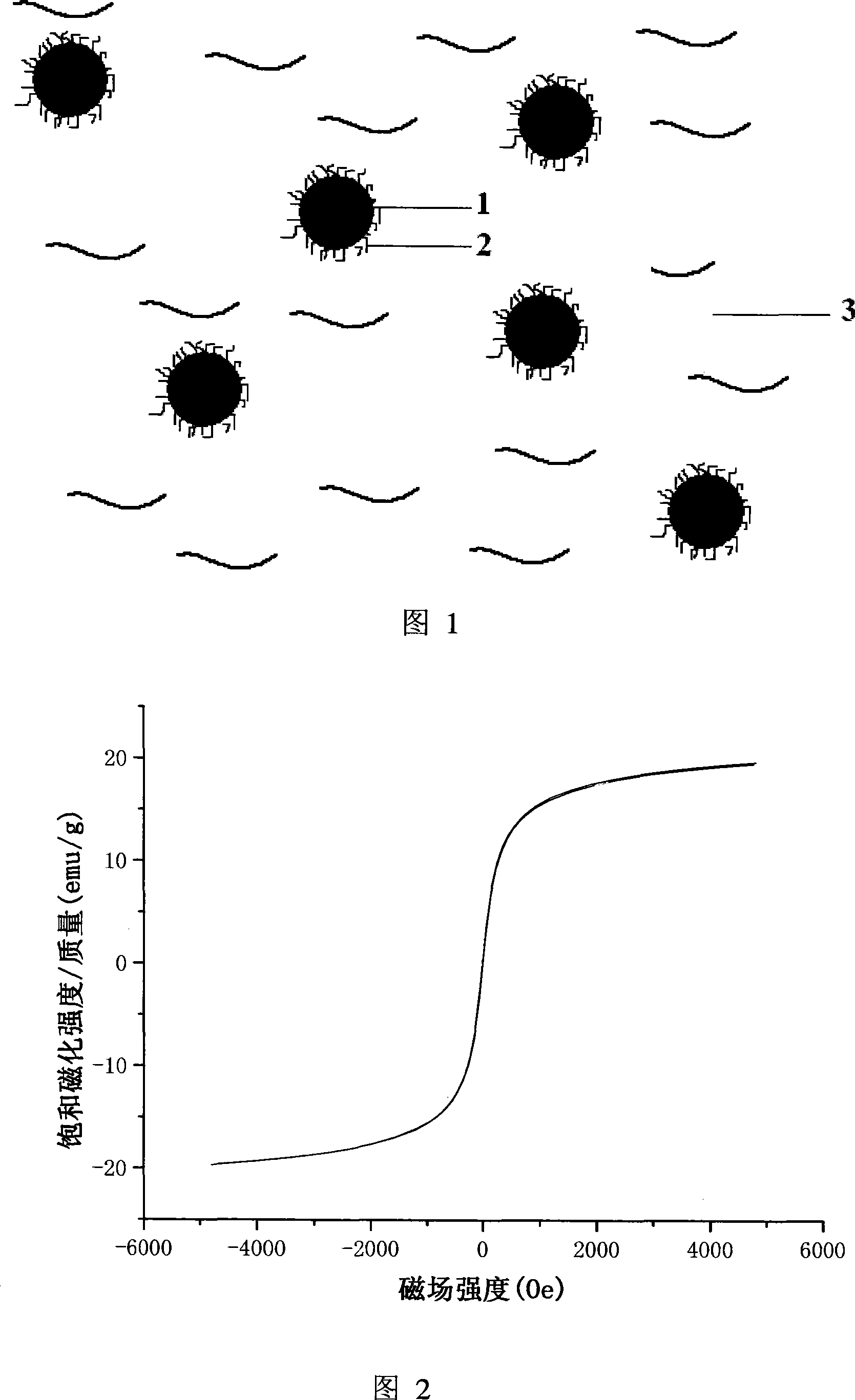

[0034] (1) Prepare 100mL Fe 2+ , Fe 3+ Mix the solution in a 250mL three-necked bottle, Fe 2+ , Fe 3+ The molar ratio is 1:1.5, about 40mL of concentrated ammonia water is added under stirring, the reaction temperature is 80°C, and the stirring speed is 400r / min. After reacting for 1 minute, add 50 mL of 0.6 g / mL sodium oleate aqueous solution and continue the reaction for 30 minutes to obtain oleic acid-modified nano-Fe 3 o 4 Magnetic Particles, Surfactants in Nano Fe 3 o 4 The adsorption structure of the particle surface is shown in Fig. 1;

[0035] (2) the modified nano-Fe obtained by step (1) reaction 3 o 4 The magnetic particles are washed repeatedly with distilled water until the conductivity of the washing liquid is σ≤30μs / cm, and the wet-state modified nano-Fe obtained after washing 3 o 4 After the magnetic particles are cleaned with ethanol solution and the supernatant is separated b...

Embodiment 2

[0037] Example 2 Preparation of ethyl silicone oil-based magnetic liquid

[0038] (1) Prepare 100mL Fe 2+ , Fe3+ Mix the solution in a 250mL three-necked bottle, Fe 2+ , Fe 3+ The molar ratio is 1:1.5, about 40mL of concentrated ammonia water is added under stirring, the reaction temperature is 80°C, and the stirring speed is 400r / min. After reacting for 1 minute, add 50 mL of 0.6 g / mL sodium oleate aqueous solution and continue the reaction for 30 minutes to obtain oleic acid-modified nano-Fe 3 o 4 magnetic particles;

[0039] (2) the modified nano-Fe obtained by step (1) reaction 3 o 4 The magnetic particles are washed repeatedly with distilled water until the conductivity of the washing liquid is σ≤30μs / cm, and the wet-state modified nano-Fe obtained after washing 3 o 4 After the magnetic particles are washed with acetone solution and the supernatant is separated by magnetic separation, they are placed in a nitrogen-protected drying oven for drying treatment at a te...

Embodiment 3

[0041] Example 3 Preparation of ethyl silicone oil-based magnetic liquid

[0042] (1) Prepare 50mL Fe 2+ , Fe 3+ Mix the solution in a 500mL beaker, Fe 2+ , Fe 3+ The molar ratio is 1:1.5, about 20mL of concentrated ammonia water is added under stirring, the reaction temperature is 80°C, and the stirring speed is 350r / min. After reacting for 5 minutes, add 10 mL of ethanol solution containing 0.71 g oleoyl sarcosine, and continue the reaction for 35 minutes to obtain oleoyl sarcosine-modified nano-Fe 3 o 4 magnetic particles;

[0043] (2) the modified nano-Fe obtained by step (1) reaction 3 o 4 The magnetic particles are washed repeatedly with distilled water until the conductivity of the washing liquid is σ≤30μs / cm, and the wet-state modified nano-Fe obtained after washing 3 o 4 After cleaning the magnetic particles with ethanol solution and separating the supernatant by magnetic separation, place them in a nitrogen-protected drying oven for drying treatment at a tem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Saturation magnetization | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Saturation magnetization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com