Series production technology of biurea

A production process, the technology of biurea, applied in the field of continuous production of biurea, can solve the problems of high chemical oxygen consumption, high cost, and difficult post-treatment of wastewater, and achieve fast reaction speed, high cost, and difficult post-treatment big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Get 500ml hydrazine hydrate solution and 125g urea, wherein the content of hydrazine hydrate in the middle of the hydrazine hydrate solution is 10% (referring to " weight percent content ", the same below), be placed in the 1000ml four of heating, electric stirring, thermometer and reflux device In the flask, the temperature was raised to 102°C, and part of the condensed water was refluxed. The content of urea and hydrazine hydrate in the reaction solution was detected every half hour, and after 13 hours, the content of hydrazine hydrate was 0.9%.

[0039] Another 400ml of hydrazine hydrate solution (10% hydrazine hydrate content) was added to 100ml of mother liquor (0.9% hydrazine hydrate content), and the control conditions were as above. After 11.5 hours, the hydrazine hydrate content was 0.9%.

[0040] The comparison of the above results shows that the reuse of mother liquor can accelerate the reaction speed.

Embodiment 2

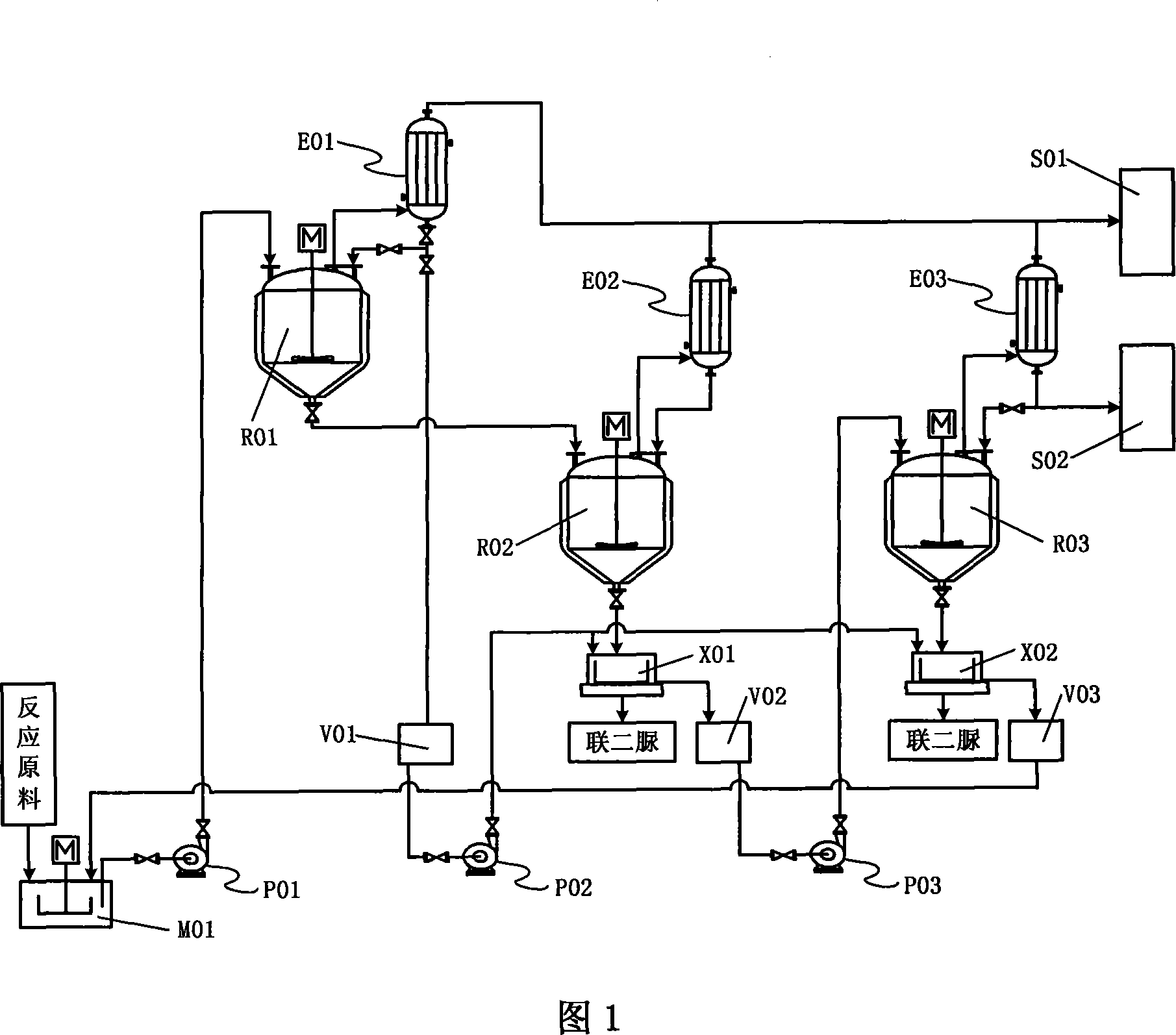

[0042] The three-pot process shown in Figure 1 is adopted. The volume of the first reactor R01 is 400 liters, and the volumes of the second reactor R02 and the third reactor R03 are both 350 liters. The hydrazine hydrate solution with a hydrazine hydrate content of 10% is used as a raw material, and the urea consumption is determined according to the material ratio of "hydrazine hydrate: urea = 1: 6". In addition, the mother liquor is added to form a mixed solution with a hydrazine hydrate content of 5.8%. The first reactor R01 is then fed with a feed rate of 250 liters per hour. The bottom material of R01 enters R02 continuously, the bottom material of R02 continuously enters the solid-liquid separation device, the mother liquor separated by X01 continuously enters R03, the mother liquor produced by the separation of R03 bottom material by X02 returns to M01, and the solid separated by X01 and X02 is combined Diurea. The reaction temperatures of R01, R02, and R03 are all gr...

Embodiment 3

[0044] Still using the three-pot process shown in Figure 1. The volume of the first reactor R01 is 400 liters, and the volumes of the second reactor R02 and the third reactor R03 are both 350 liters. The material ratio of hydrazine hydrate and urea is 1: 3.9, the content of hydrazine hydrate in the middle of the raw material hydrazine hydrate solution is 10%, and the concentration of hydrazine hydrate in the mixed solution made after adding the mother liquor is 6.5%, and the first reaction kettle R01 per hour The total feed volume is 180 liters. The bottom material of R01 enters R02 continuously, the bottom material of R02 continuously enters the solid-liquid separation device, the mother liquor separated by X01 continuously enters R03, the mother liquor produced by the separation of R03 bottom material by X02 returns to M01, and the solid separated by X01 and X02 is combined Diurea. The reaction temperatures of R01, R02, and R03 are all greater than 100°C, and the reaction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com