Method for preparing metallic titanium by electrolyzing TiCl4 molten salt and electrolysis bath thereof

A technology of molten salt electrolysis and electrolytic cell, which is applied in the field of TiCl4 molten salt electrolysis to produce powdered titanium metal and electrolytic cell, which can solve problems such as deformation, corrosion of furnace body and equipment, large changes in thermal balance and material balance of electrolytic cell, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

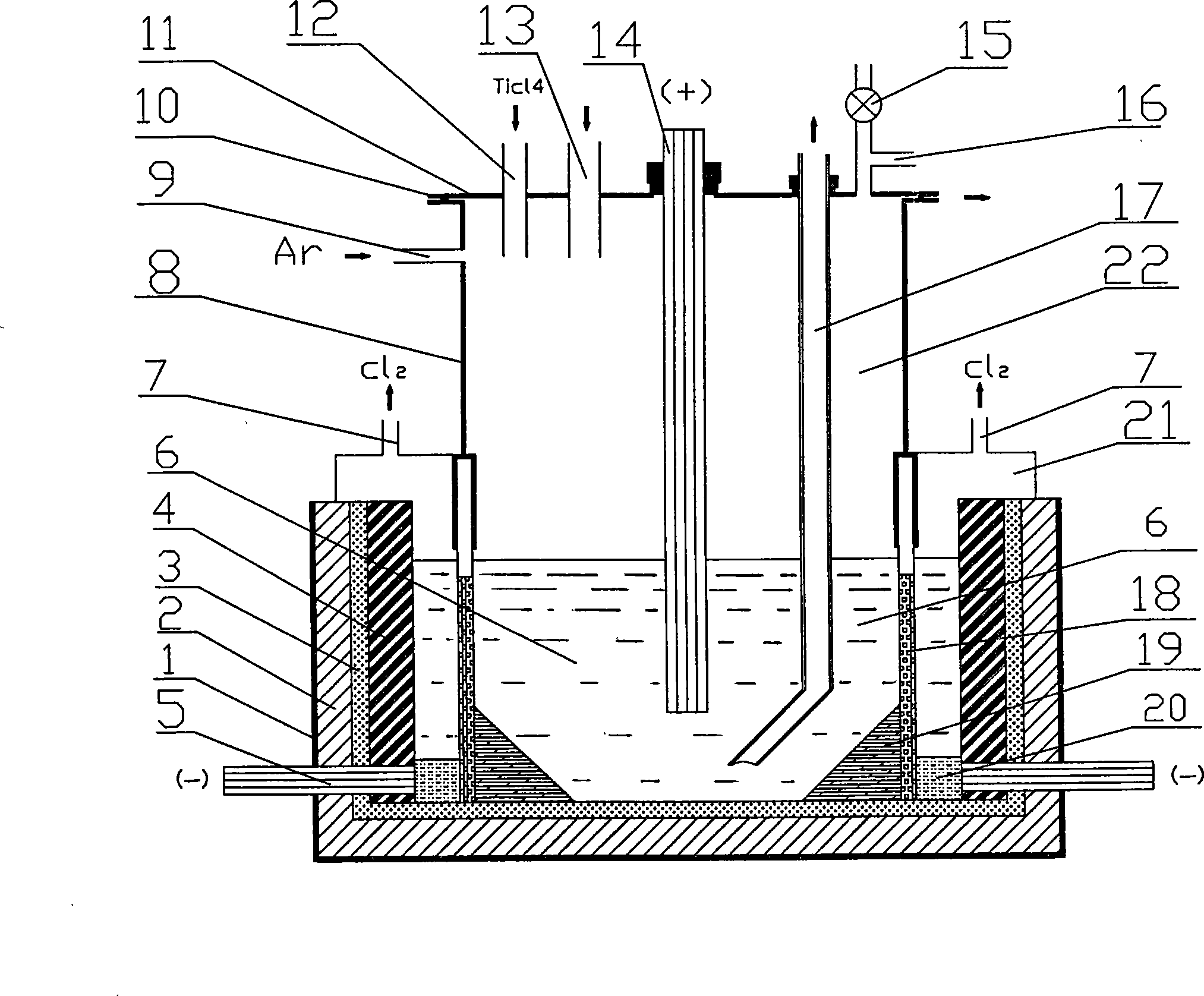

[0019] As shown in the accompanying drawings, the low-temperature TiCl of the present invention 4 The molten salt electrolytic cell has a steel tank shell 1, the tank shell 1 is lined with insulation bricks 2, the insulation bricks are lined with refractory bricks 3, and the side part in contact with the electrolyte melt 6 is lined with Graphite anode 4, the bottom of graphite anode 4 is connected with anode steel rod 5, and stretches out of the tank shell, and steel electrolytic cell cathode 14 is vertically installed in the middle of the electrolytic cell, and its lower part extends into the electrolyte melt 6; Between the graphite anode 4 and the steel cathode 14 of the electrolytic cell, there is a ceramic or refractory material with a large opening porosity in the lower part and no pores in the upper part, good corrosion resistance and thermal shock resistance. Partition plate 18, installed above the partition plate 18 made of ceramic or refractory material is a metal cyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com