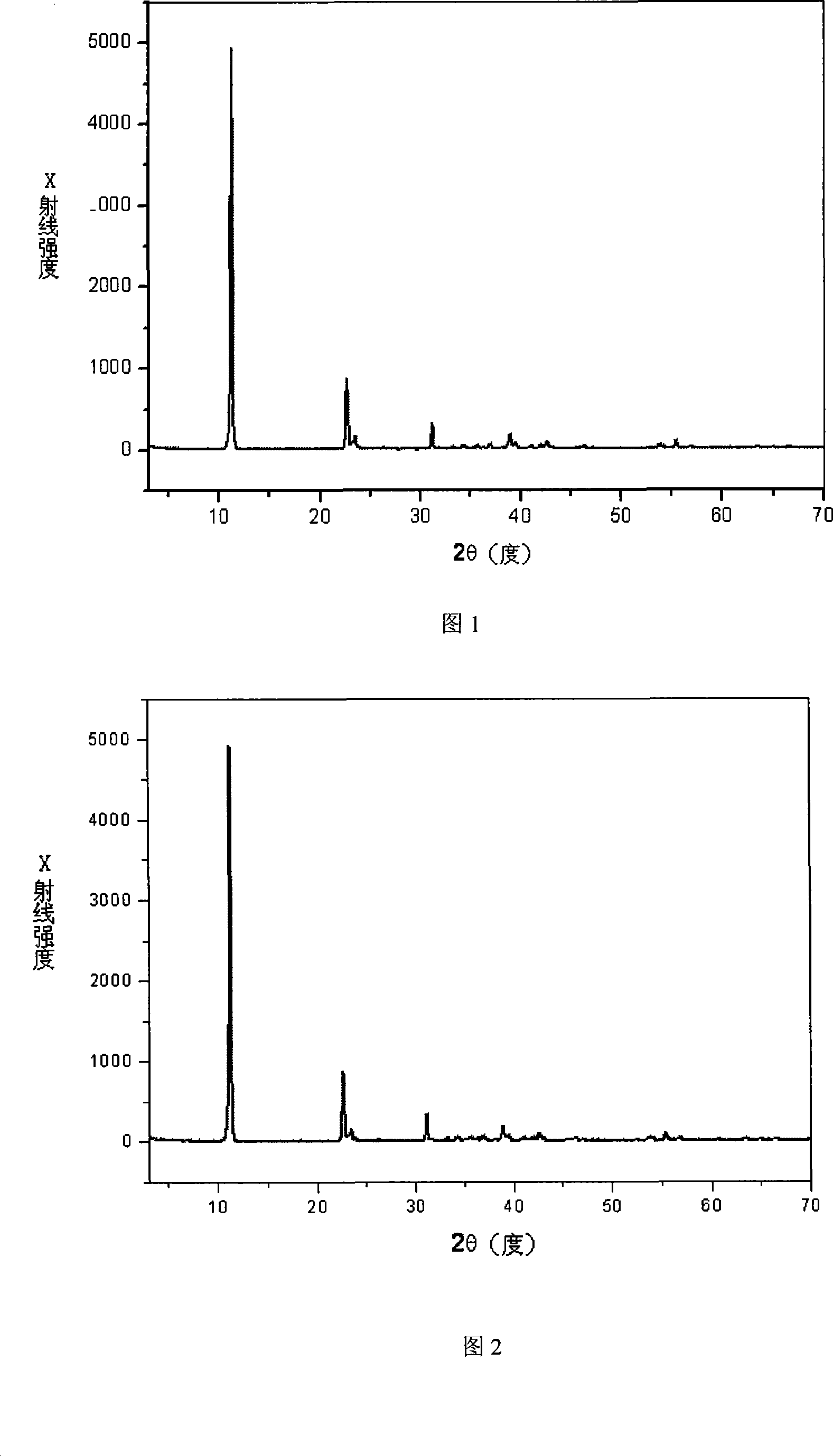

Method for preparing calcium aluminum hydrotalcite used as concrete additive

A technology of concrete admixture and hydrotalcite, applied in chemical instruments and methods, aluminum compounds, calcium/strontium/barium compounds, etc., can solve the problems of long process steps and time-consuming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] 79.6g of aluminum chloride hexahydrate and 97.0g of calcium chloride dihydrate were simultaneously dissolved in a mixed solution containing 670mL of deionized water and 330mL of anhydrous methanol. Dissolve 100 g of sodium hydroxide in another mixed solution of 670 mL of deionized water and 330 mL of anhydrous methanol. First adjust the slit of the total back-mixing explosive nucleation reactor to 2. Use a peristaltic pump to simultaneously pump the salt solution and the alkali solution into the total back-mixing explosive nucleation reactor at a speed of 200 ppm, and adjust the voltage to 100 to turn on the colloid mill for stirring. A 5L crystallization vessel was used to terminate the reacted slurry under the fully back-mixed explosive nucleation reactor. After the reaction was completed, the crystallization container was placed in a crystallization heater whose temperature was set at 70° C. for 1 day. Then the crystallization container was taken out and cooled to ...

Embodiment 2

[0027] 39.8g of aluminum chloride hexahydrate and 48.5g of calcium chloride dihydrate were simultaneously dissolved in a mixed solution containing 300mL of deionized water and 200mL of n-propanol. Dissolve 47.5 g of sodium hydroxide in another mixed solution of 300 mL of deionized water and 200 mL of n-propanol. First adjust the slit of the full back-mixing explosive nucleation reactor to 4. Use a peristaltic pump to simultaneously pump the salt solution and the alkali solution into the total back-mixing explosive nucleation reactor at a speed of 150 ppm, and adjust the voltage to 180 to turn on the colloid mill for stirring. A 3L crystallization vessel was used to terminate the reacted slurry under the fully back-mixed explosive nucleation reactor. After the reaction was completed, the crystallization container was placed in a crystallization heater whose temperature was set at 100° C. for 1 day. After cooling the highly crystallized vessel to room temperature, the product ...

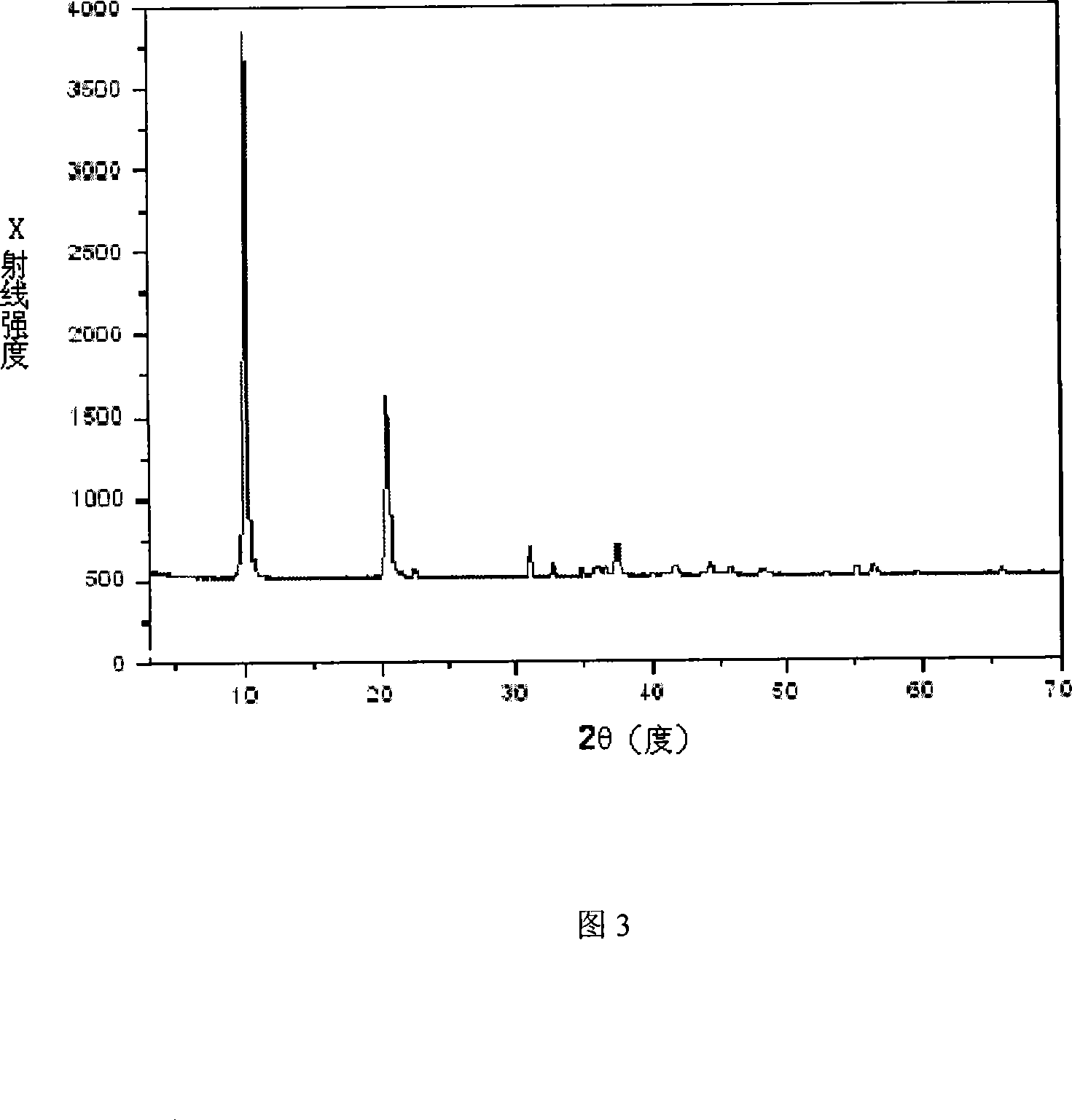

Embodiment 3

[0029]123.8 g of aluminum nitrate nonahydrate and 155.9 g of calcium nitrate hexahydrate were simultaneously dissolved in a mixed solution containing 750 mL of deionized water and 250 mL of acetone. Dissolve 95 g of sodium hydroxide in another mixture of 750 mL of deionized water and 250 mL of acetone. First adjust the slit of the total back-mixing explosive nucleation reactor to 6. Use a peristaltic pump to simultaneously pump the salt solution and the alkali solution into the total back-mixing explosive nucleation reactor at a speed of 100 ppm, and adjust the voltage to 150 to turn on the colloid mill for stirring. A 5L crystallization vessel was used to terminate the reacted slurry under the fully back-mixed explosive nucleation reactor. After the reaction was completed, the crystallization container was placed in a crystallization heater whose temperature was set at 20° C. for 1 day. Then the crystallization container was taken out and cooled to room temperature, the pro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com