Integrated methane-producing denitrogenation dephosphorization desulfurization sewage treatment method and device thereof

A sewage treatment method, nitrogen and phosphorus removal technology, applied in biological sludge treatment, anaerobic digestion treatment, waste fuel, etc. Good quality effect, full contact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

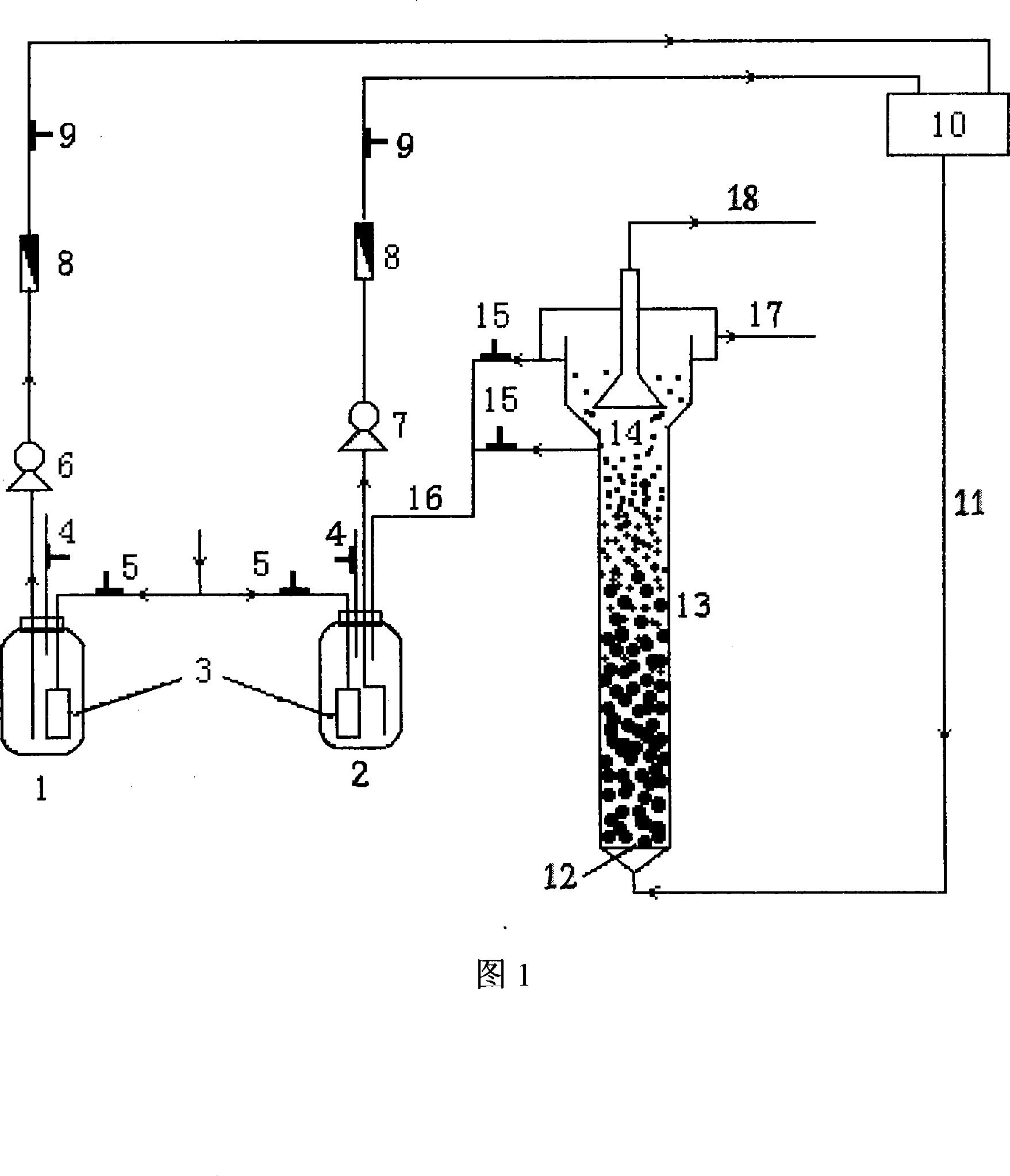

[0055] The integrated methane-producing, nitrogen-removing, phosphorus- and sulfur-removing sewage treatment device of the present invention is shown in FIG.

[0056] The high-speed anaerobic granular sludge reactor 13 is made of plexiglass, and the whole reactor is divided into two parts: a reaction zone and a sedimentation zone. Among them, the inner diameter of the reaction zone is 100mm, the height is 1.7m, and the volume is 12.0L; the inner diameter of the precipitation zone is 140mm, the height is 0.6m, and the volume is 6.0L.

[0057] The sewage storage tank 1 is used to store sewage, and the backflow water storage tank 2 is used to store backflow water. They communicate with the water tank 10 through the water inlet pump 6 , the backflow pump 7 , and respective flowmeters 8 and valves 9 . An aeration head 3 is arranged in the sewage storage tank 1 and the return water storage tank 2 respectively, and the aeration head 3 is selectively aerated into the sewage storage ta...

Embodiment 2

[0070] The dewatered sludge from the digestion tank of a sewage treatment plant in Taiyuan was used for activity recovery and then inoculated into the experimental reactor. The domestic sewage was taken from a family area of a university in Harbin, and the COD concentration of the sewage influent was 146-563mg / L. Using self-prepared beer wastewater, inoculate a small amount of granular sludge and municipal digested sludge into the reactor at a mass ratio of 1:6, start the operation at 35°C, maintain HRT3.4h, and reduce the influent COD from 200mg / L increased to 1000mg / L, influent load from 1.58kgCOD / m 3 ·d increased to 7.5kgCOD / m 3 d, Granular sludge was formed rapidly, the reactor was successfully started, the sludge concentration reached 32.7g / L, VSS / SS reached 0.66, and the COD removal rate reached 92%. If this reactor does not go through any adaptation process, it can directly treat the actual domestic sewage, and it can achieve good operation results: when the influent...

Embodiment 3

[0073] Take the dewatered sludge from the digestion tank of a sewage treatment plant in Taiyuan for activity recovery and inoculate it into the reactor used for the experiment. The beer wastewater is taken from a brewery in Taiyuan. The operation is started at 35°C, and the influent COD concentration is 867-3750mg / L. The formation of granular sludge is promoted by means of low influent concentration and high organic load. Low influent concentration of about 500mg / L, high influent flow rate of 3.0L / h, high return flow rate of 12L / h, high liquid rising velocity of 2.5m / h, 2.88kgCOD / m 3 · Run for a week under the condition of about d water inflow load. From the 7th day, in order to increase the methane-producing activity of the sludge and form a stable microbial community where various microorganisms such as acid-producing bacteria and methanogenic bacteria coexist as soon as possible, the influent flow rate was reduced to 0.9L / h, and the return flow rate was reduced to 0 , th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com