Method for producing low-carbon olefins

A production method and technology for low-carbon olefins, which are applied in the production field of low-carbon olefins, can solve the problems of poor process economy, single raw material, long process route, etc., and achieve the effects of high olefin selectivity, short process route and good technical effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

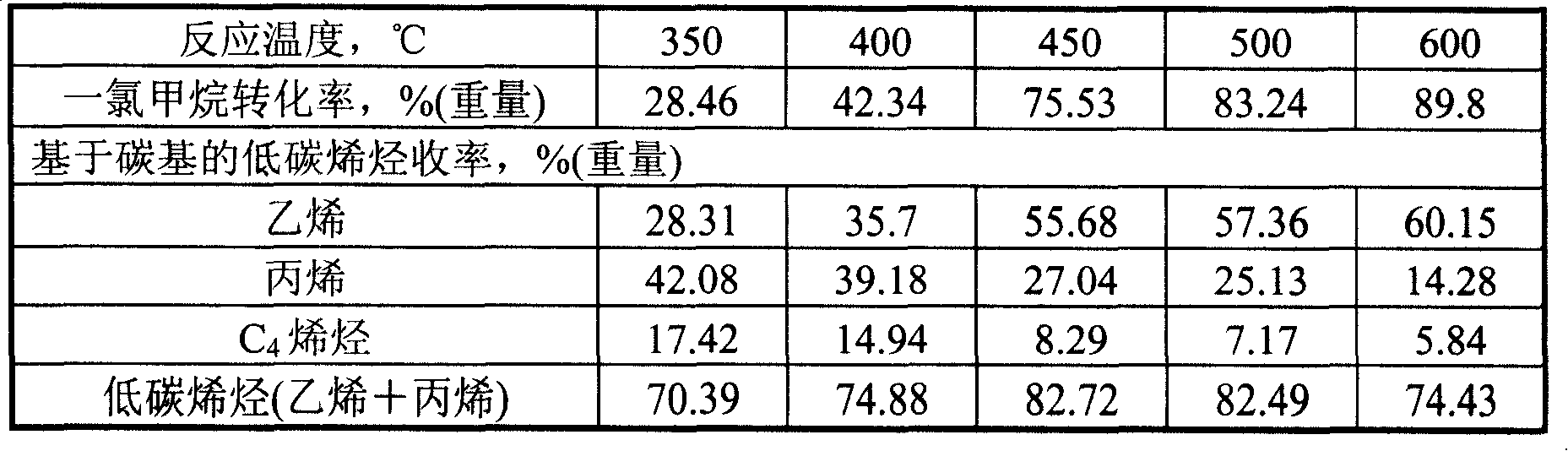

[0019] Mix 2 grams of 20-40 mesh SAPO-34 molecular sieve catalyst with quartz sand of the same particle size, the mixing mass ratio of quartz sand and catalyst is 3:1, and then put it into a φ14 316 stainless steel fixed-bed reactor to ensure that the The particles are in the constant temperature zone of the reactor. The raw material is monochloromethane, which is operated at normal pressure. After passing through the mass flow meter, it is preheated and mixed with diluent (steam) to enter the reactor. The volume ratio of diluent to monochloromethane is 0.1:1, based on the weight of monochloromethane Hourly space velocity WHSV is 1 hour -1 . Products were analyzed by gas chromatography with thermal conductivity detector. The temperature of the constant temperature reaction zone in the reactor was adjusted, and the results of the reaction time of 1 hour were shown in Table 1.

[0020] Table 1

[0021]

Embodiment 6~8

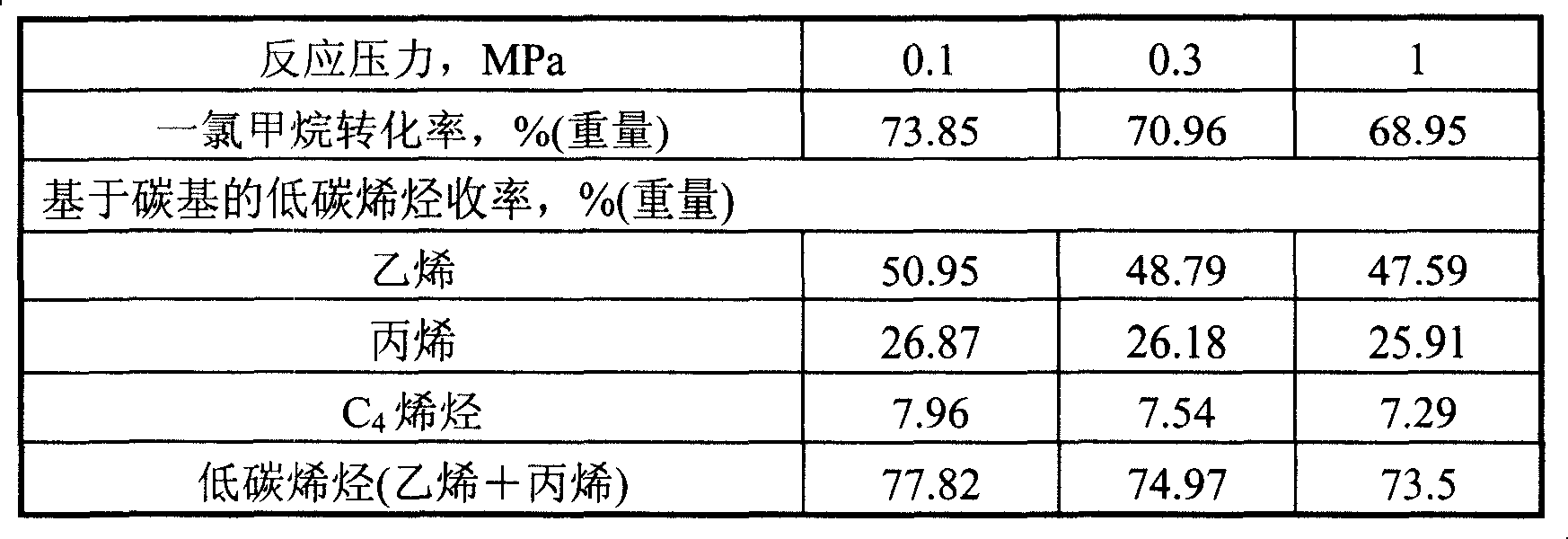

[0023] According to the experimental conditions of Example 3, the reactor pressure was changed while ensuring that the linear velocity in the reactor was the same as in Example 3, and the results of the reaction time of 1 hour were shown in Table 2.

[0024] Table 2

[0025]

Embodiment 9~11

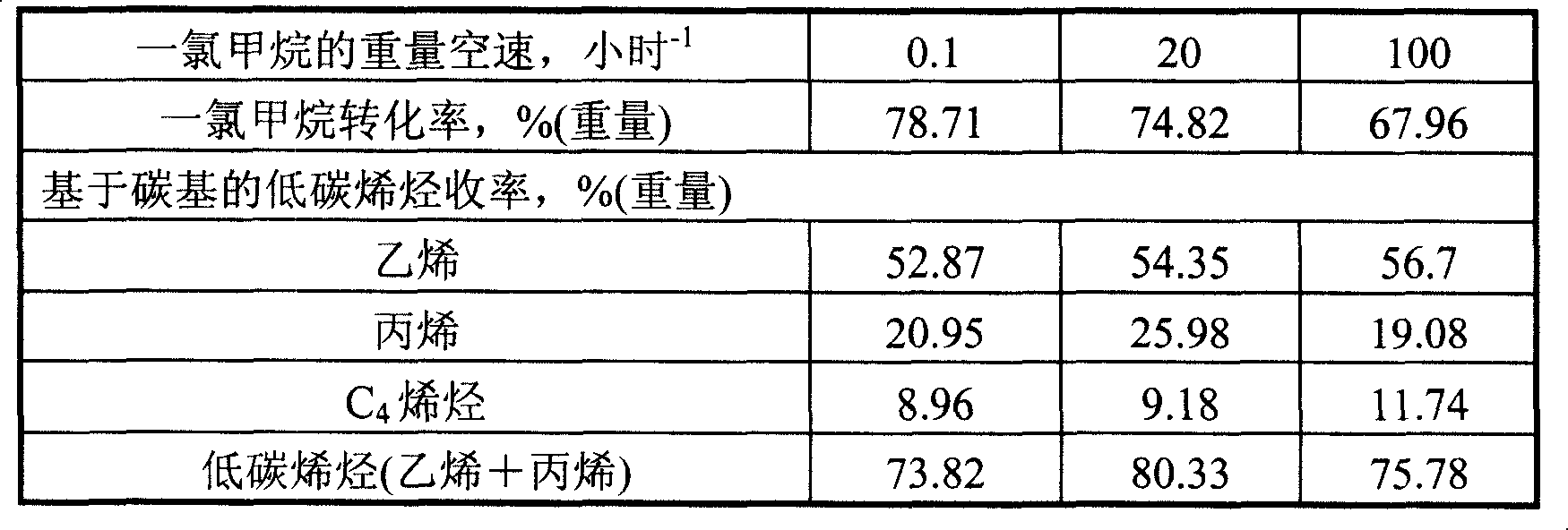

[0027] According to the experimental conditions of Example 3, the weight hourly space velocity WHSV based on monochloromethane was changed, and the reaction time was 1 hour. The results are shown in Table 3.

[0028] table 3

[0029]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com