Optical emission interferometry for PECVD using a gas injection hole

A technology for gas and gas distribution, applied in the direction of measuring devices, optical devices, electrical components, etc., can solve the problem of not providing benefits, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

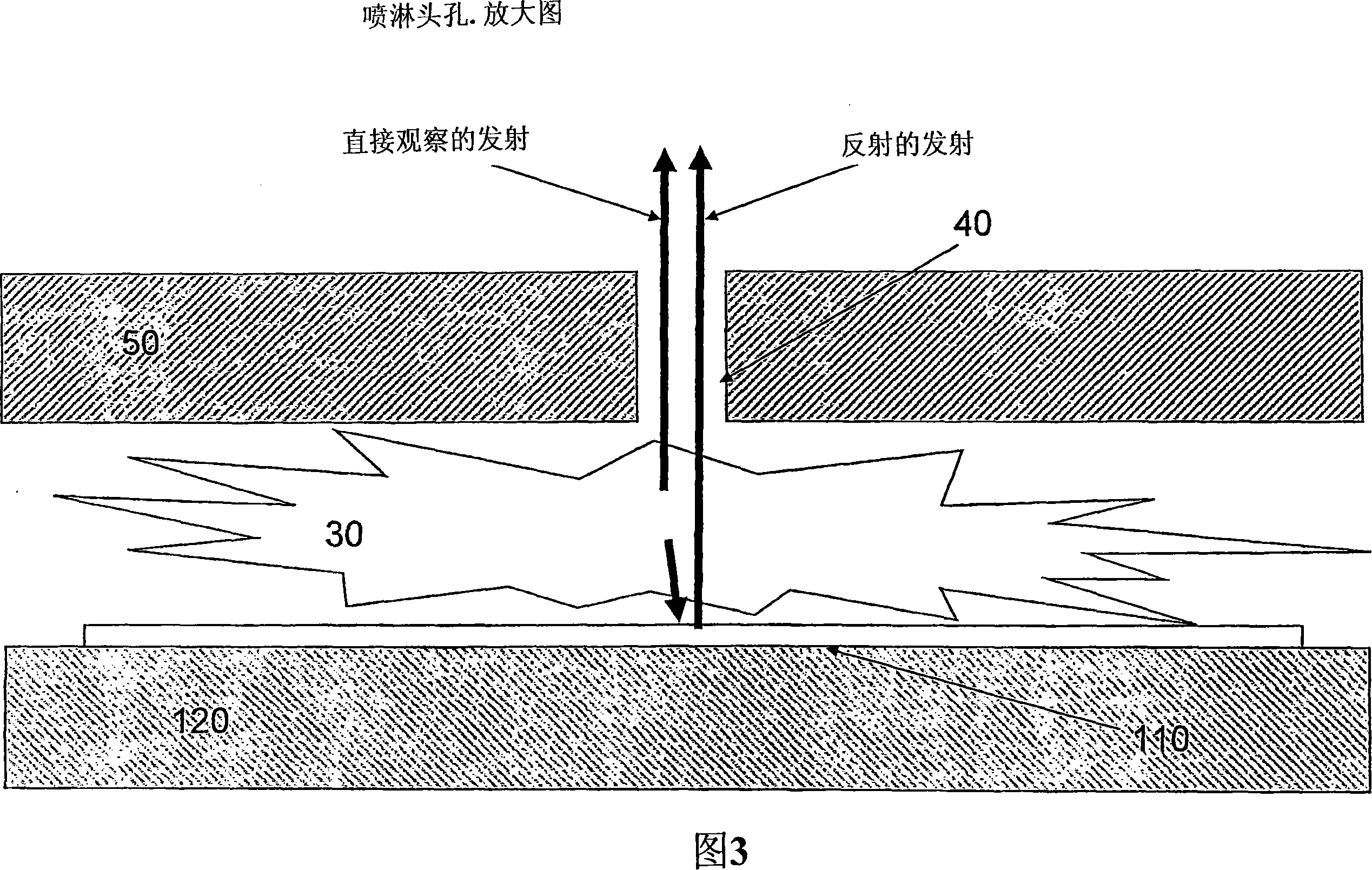

[0066] Accurate measurement of film thickness in real time allows the process to be terminated when a predetermined film thickness has been achieved. This is shown in Figure 7, where the process was terminated when the target film thickness of 7500 Ȧ was achieved. A deposition rate of 498.8 A / min was determined using linear regression analysis.

[0067] An advantage of terminating processes based on this technique relative to conventional methods of terminating by time is that better run-to-run repeatability is achieved, resulting in devices with more consistent performance. From one run to another, the deposition rate will normally vary slightly due to film buildup, which will change the reactor characteristics. Terminating the process at a fixed time inevitably results in film thickness, which also varies from run to run. Additionally, the system must be periodically cleaned using a plasma cleaning process to remove the accumulated film. After this procedure, the depositi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com