Extrusion blow moulding wall-thickness on-line control system based on image recognition technology and method thereof

A technology of extrusion blow molding and image recognition, which is applied in the field of wall thickness control of plastic extrusion blow molding products to achieve the effects of ensuring consistency, reducing scrap rate, and improving product performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

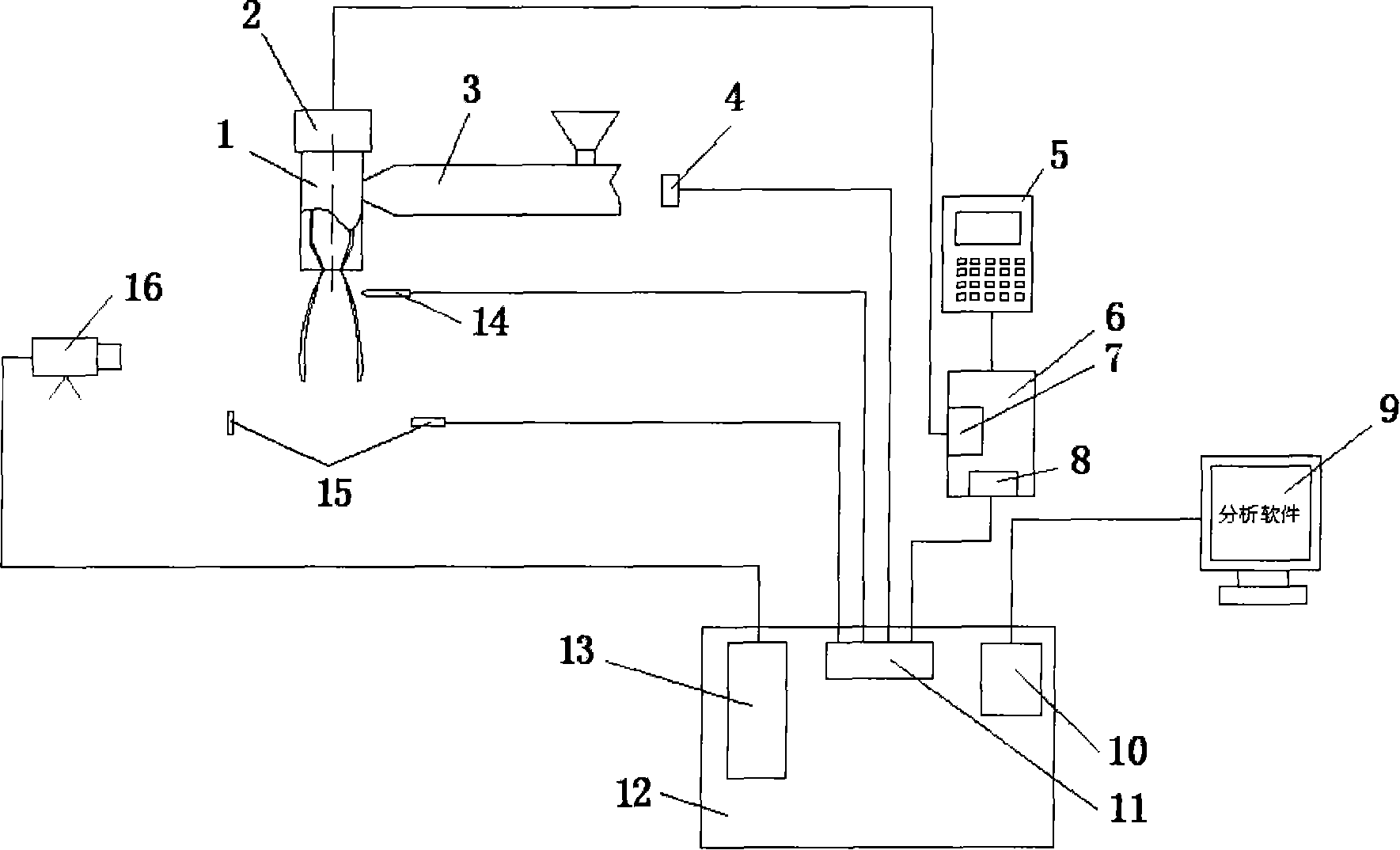

[0035] figure 1 A specific structure of the present invention is shown. Depend on figure 1 It can be seen that the wall thickness control system for extrusion blow molding products includes machine head 1, servo valve 2, extruder 3, rotational speed measuring device 4, programmable controller upper computer 5, programmable controller lower computer 6, parison wall Thick control board 7, RS232 communication card 8, display 9, video output card 10, RS232 serial port expansion card 11, industrial computer 12, image acquisition card 13, scriber 14, photoelectric sensor 15, camera 16; Described camera 16 passes through Cable is connected with image acquisition card 13, and described image acquisition card 13 is inserted on the mainboard of industrial computer 12 by PCI bus, and video output card 10 is inserted on the mainboard of industrial computer 12 by VGA bus, video output card 10 and display 9 The speed measuring device 4, the scriber 14 and the photoelectric sensor 15 are r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com