Hollow fiber film assembly

A fiber membrane and fiber membrane bundle technology, which is applied in the field of water treatment, can solve the problems of reducing the filtration uniformity of the effective area of the filtration of the membrane module, which has not been solved, and cannot be purged and washed at the root of the membrane filament.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

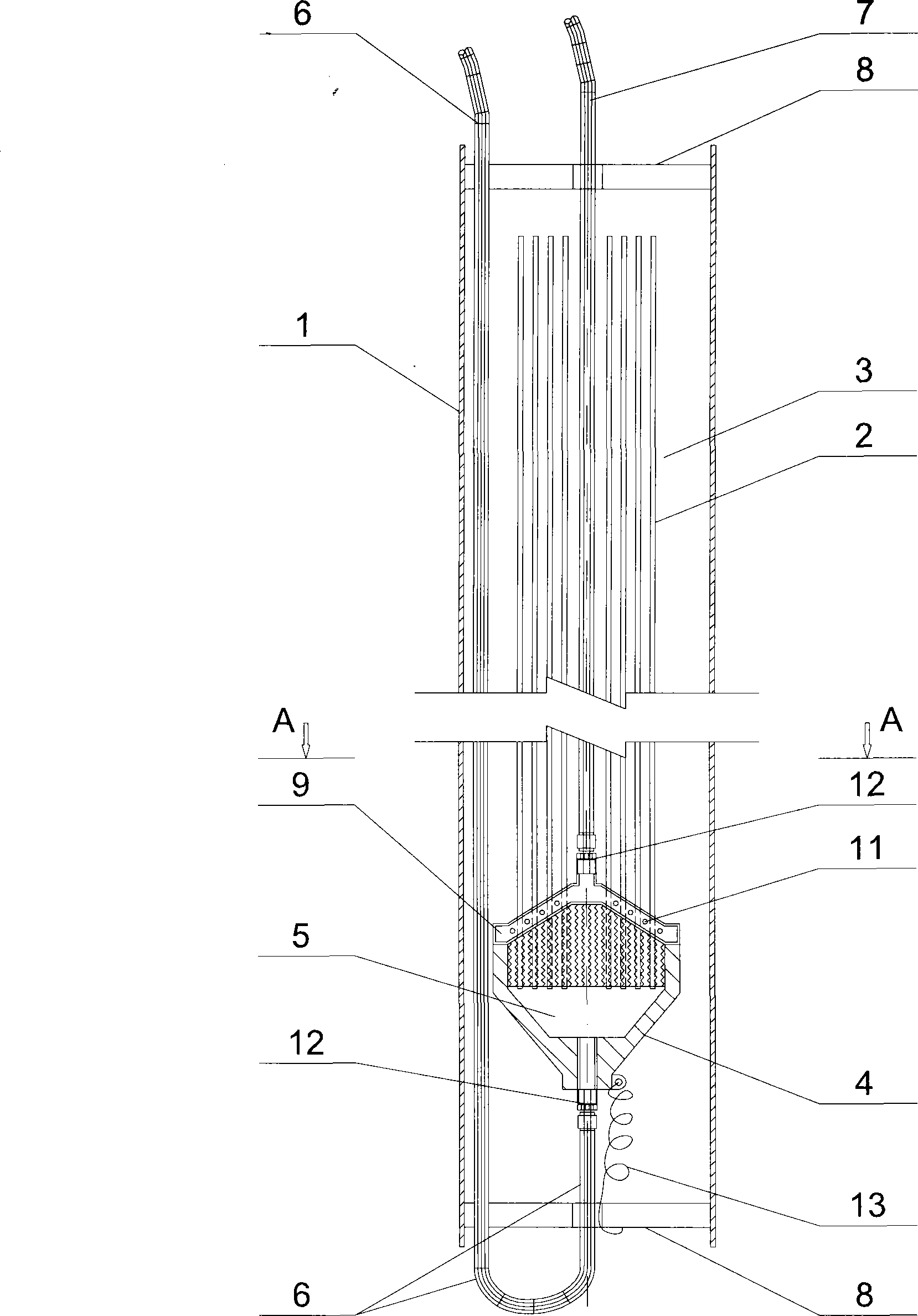

[0054] Such as figure 1 , image 3 As shown, a hollow fiber membrane module includes a housing 1 with an inner diameter of 90 mm and a material made of UPVC (un-plasticized polyvinyl chloride) plastic, and a hollow fiber composed of 240 hollow fiber membrane filaments 2 arranged in the housing 1 Membrane bundle 3, the average pore diameter of the micropores of the hollow fiber membranes 2 for passing liquid is 0.4 μm, the outer diameter of the hollow fiber membranes is 2.8 mm, the material is polyvinylidene fluoride, the upper end can swing freely, each membrane The filaments are in a closed-cell state, sealed with flexible epoxy resin, and the lower end is cast with epoxy resin and collected in the end 4, and it is re-cast with polyurethane to protect the root of the membrane filament. The overall shape of the terminal 4 is cup-shaped, and the diameter of the top circle is 60mm. Hollow fiber membranes 2 are open in the water production collection chamber 5 in the end 4, and...

Embodiment 2

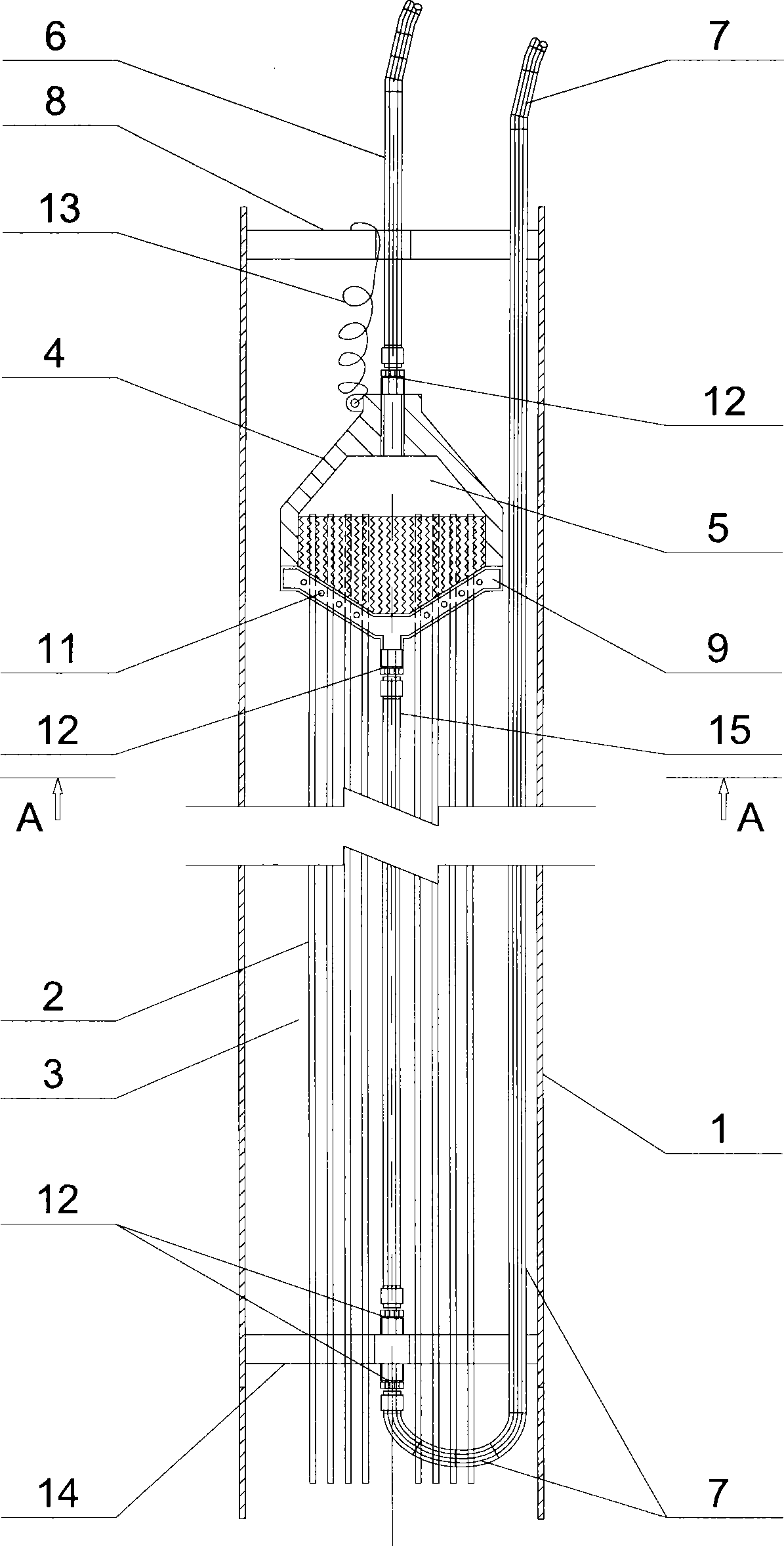

[0063] Such as figure 2 , Figure 4 As shown, a hollow fiber membrane module includes a housing 1 with an inner diameter of 65 mm and a material made of UPVC (un-plasticized polyvinyl chloride) plastic, and a hollow fiber composed of 300 hollow fiber membrane filaments 2 arranged in the housing 1 Membrane bundle 3, the average pore diameter of the micropores of the hollow fiber membranes 2 for passing liquid is 0.1 μm, the outer diameter of the hollow fiber membranes is 1.35 mm, the material is polyvinylidene fluoride, the lower end can swing freely, each membrane The filaments are in a closed-cell state, sealed with flexible epoxy resin, and the upper end is cast with epoxy resin and collected in the end 4, and it is re-cast with polyurethane to protect the root of the membrane filament. The overall shape of the terminal 4 is cup-shaped, and the diameter of the upper circle is 45 mm. Hollow fiber membranes 2 are open in the water production collection chamber 5 in the end ...

Embodiment 3

[0068] The structure of the membrane module is the same as that of Example 1.

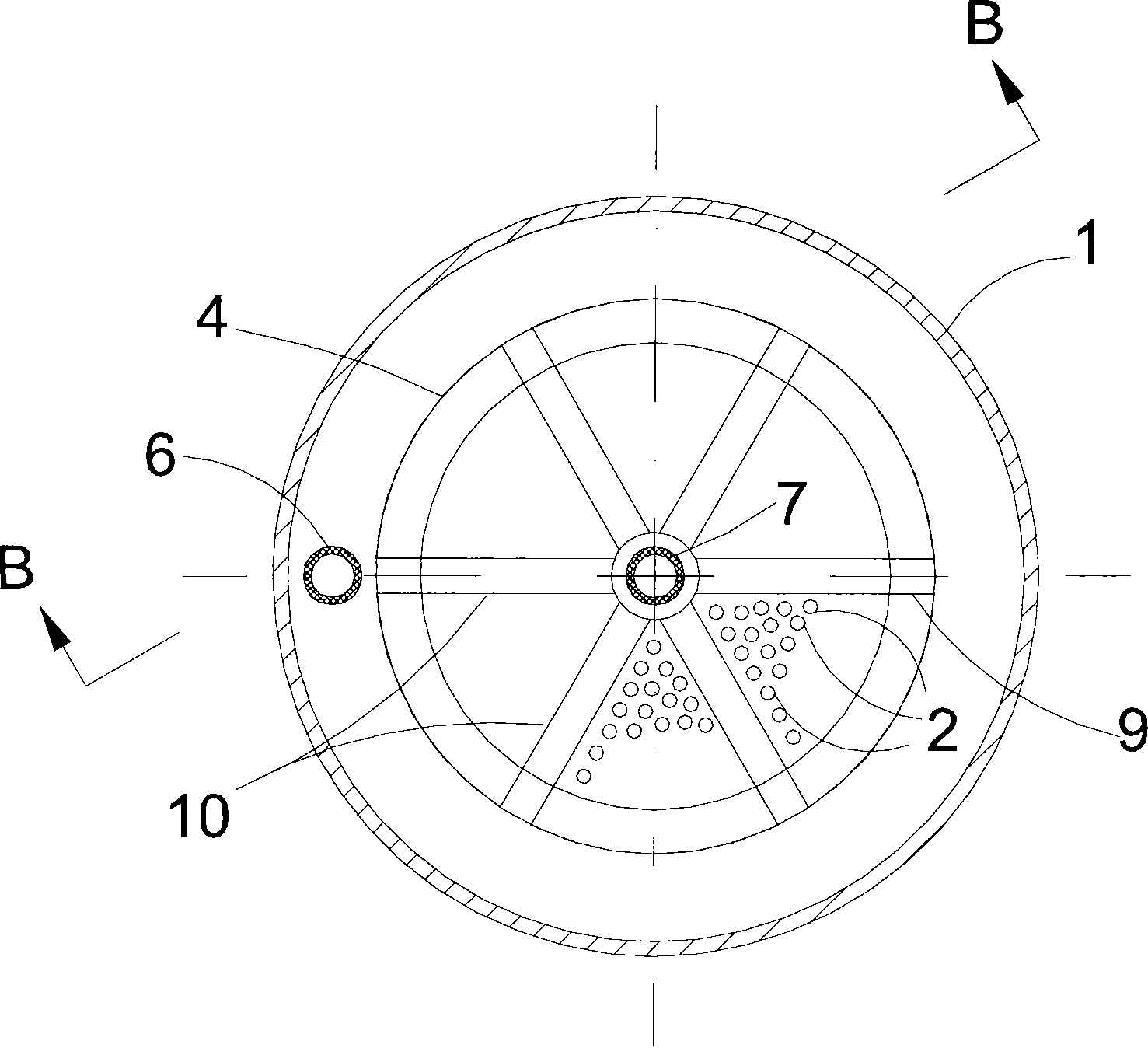

[0069] Such as Figure 7 As shown, eight hollow fiber membrane modules, water collection head 18, central pipe 19 and water outlet 20 form a radial membrane module unit. The water production pipe 6 is connected with eight quick-plug connectors 12 evenly distributed on the lower end surface of the water collection end 18 with a diameter of 150 mm. The three membrane modules are evenly distributed around the center pipe 19, and the bottom of the center pipe 19 is connected with the inlet pipes 7 of the eight hollow fiber membrane modules through eight quick-plug connectors 12. When the membrane module unit is working, the hollow fiber membrane bundle 3 is surrounded by the liquid to be filtered, and the compressed air provided by the air source enters from the upper opening of the central pipe 19, and enters the inlet pipe 7 of the eight membrane modules, and finally passes through the terminal 4. Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com