Ultraviolet electricity scaling hot-dispelling electric detector

A pyroelectric detector, pyroelectric technology, applied in the direction of electrical radiation detectors, etc., can solve the problems of no detector, unpractical application, unsuitability, etc., to enhance photoelectric equivalence, thickness and uniform performance Accurate control, fast response effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Taking the lithium tantalate pyroelectric detector as an example below, the specific implementation of the present invention will be further described in detail in conjunction with the accompanying drawings:

[0019] First cut the lithium tantalate crystal polarized along the direction into 14mm×18mm wafers with a thickness of 0.7mm, grind and polish the first side of the wafer, then grind the second side and polish to 80μm, after equal thickness correction , the uniform thickness deviation of the entire sheet is ≤±1μm. It was etched with 40% analytical pure HF at 95°C for 1 hour, and then cleaned.

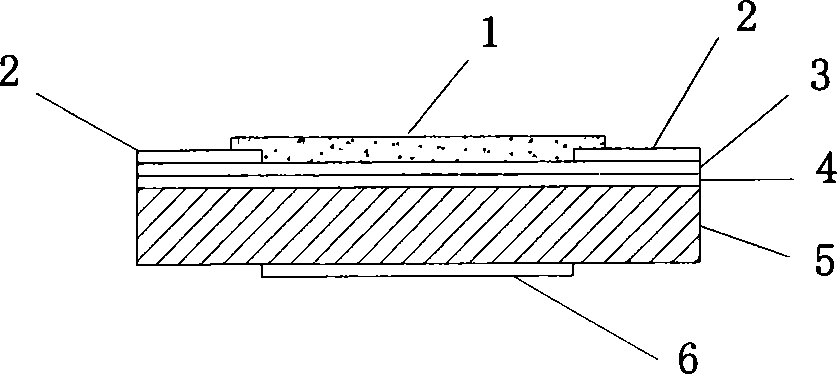

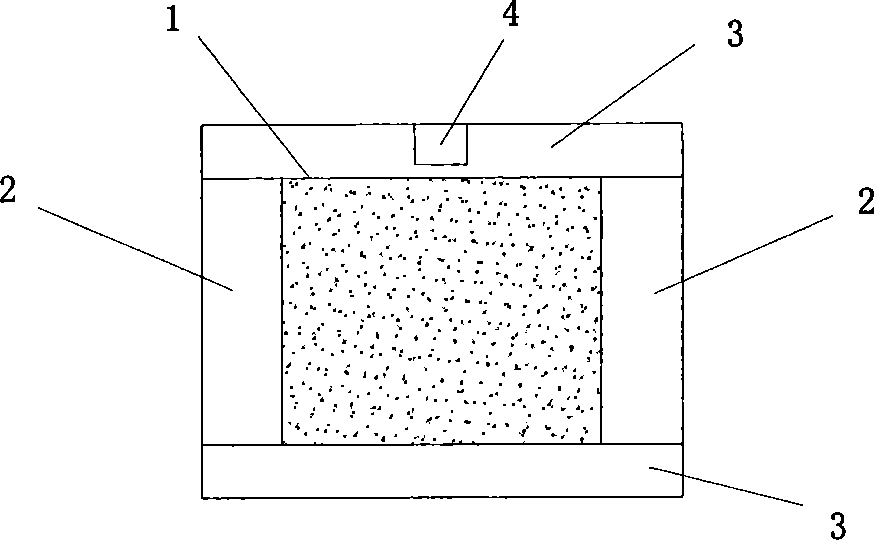

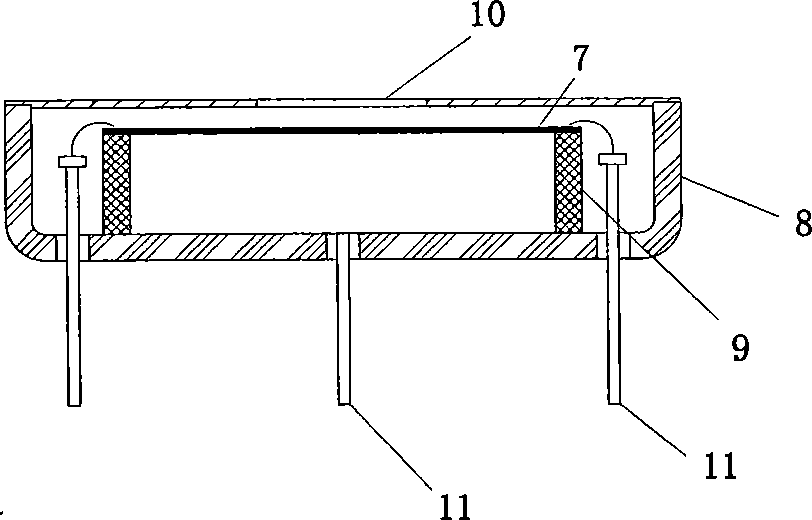

[0020] The Cr / Au signal electrode layer 6 of 10mm * 10mm is evaporated in the middle of the lower surface of the lithium tantalate wafer 5, and the Cr / Au upper electrode layer 4 is evaporated on the upper surface of the entire lithium tantalate wafer. The sheet resistance of the electrode layers 4 and 6 is less than 5Ω / □. Then, a layer of polyimide shielding layer 3 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com