Liquid crystal alignment agents for forming horizontal alignment film and liquid crystal display element

A liquid crystal aligning agent, a technology of horizontal alignment, applied in the directions of liquid crystal materials, chemical instruments and methods, optics, etc., can solve the problems of poor solubility, poor liquid crystal alignment, uneven film thickness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

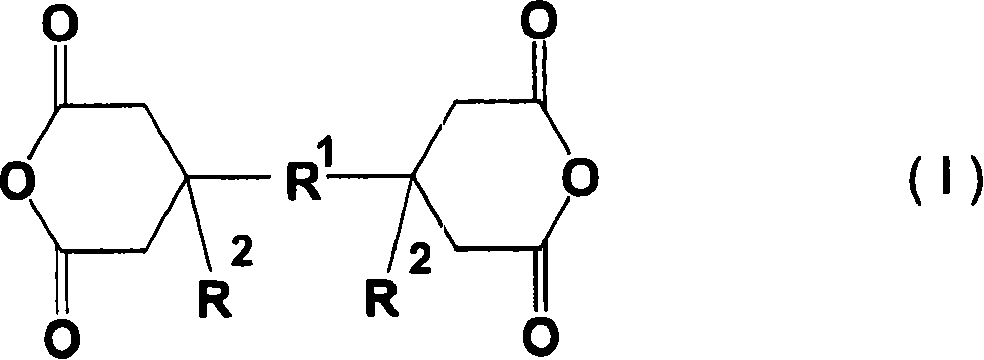

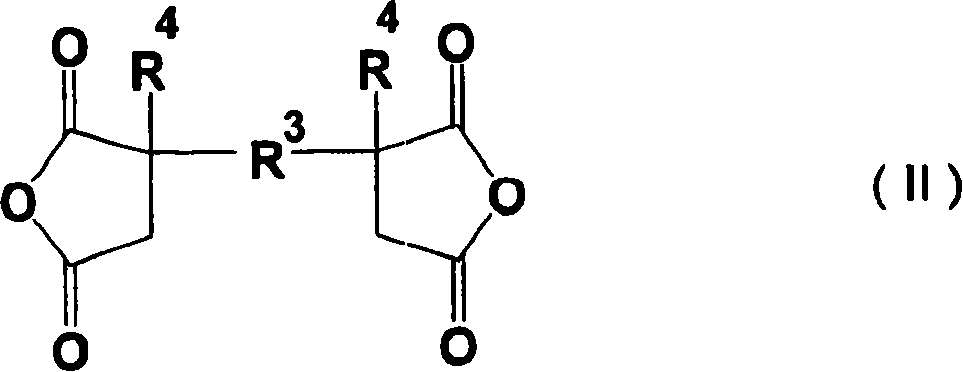

Method used

Image

Examples

Embodiment

[0111] [printability]

[0112]

[0113] The polymer was dissolved in a mixed solvent of γ-butyrolactone / N-methylpyrrolidone / butyl cellosolve / the third solvent to prepare a solution with a solid content concentration of 4% by weight, and the solution was passed through a filter with a pore size of 0.2 μm Filtrate to prepare the liquid crystal aligning agent of the present invention. The above-mentioned liquid crystal alignment agent was coated on the transparent electrode surface of a glass substrate with a transparent electrode formed of an ITO film using a JET-CM continuous inkjet printer (Kishu Giken Industry Co., Ltd.), and the coated substrate was left to stand. 1 minute. It was dried on a hot plate at 80° C. for 1 minute, and then dried on a hot plate at 180° C. for 20 minutes to form a film with an average film thickness of 600 Ȧ. This substrate was observed with a microscope at a magnification of 20 times, and it was judged as "good" when there was no coating uneven...

Synthetic example 1

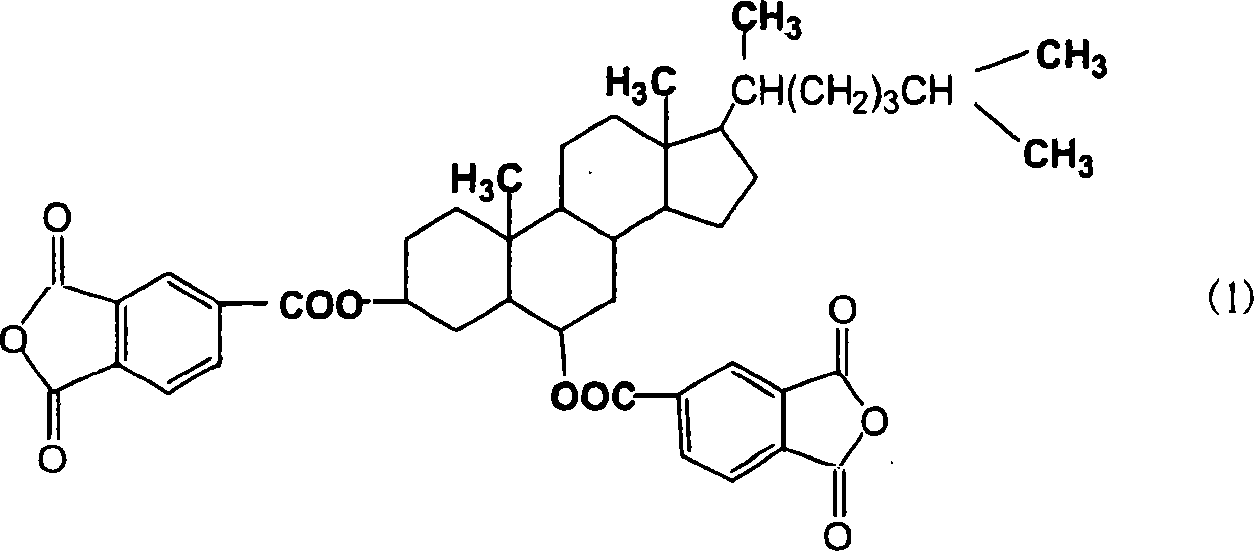

[0122] 112g (0.5mol) of 2,3,5-tricarboxycyclopentylacetic dianhydride as tetracarboxylic dianhydride and 157g (0.5mol) of 1,3,3a,4,5,9b-hexahydro-8- Methyl-5-(tetrahydro-2,5-dioxo-3-furyl)-naphtho[1,2-c]-furan-1,3-dione, 95 g (0.875 mol) as diamine Compound p-phenylenediamine, 25g (0.1mol) bisaminopropyl tetramethyldisiloxane, 13g (0.01mol) 3,6-bis(4-aminobenzoyloxy)cholestane, 8.1g (0.03 mol) of n-octadecylamine as a monoamine was dissolved in 960 g of N-methyl-2-pyrrolidone, and reacted at 60° C. for 6 hours. A small amount of the obtained polyamic acid solution was fractionated, NMP was added, and the viscosity was measured with a solution having a solid content concentration of 10% by weight, and it was 60 mPa·s. Next, 2,700 g of N-methyl-2-pyrrolidone was added to the obtained polyamic acid solution, 396 g of pyridine and 409 g of acetic anhydride were added, and dehydration ring closure was performed at 110° C. for 4 hours. After the imidization reaction, replace the s...

Synthetic example 2

[0124]112g (0.5mol) of 2,3,5-tricarboxycyclopentylacetic dianhydride as tetracarboxylic dianhydride and 157g (0.5mol) of 1,3,3a,4,5,9b-hexahydro-8- Methyl-5-(tetrahydro-2,5-dioxo-3-furyl)-naphtho[1,2-c]-furan-1,3-dione, 96 g (0.885 mol) as diamine Compound p-phenylenediamine, 25g (0.1mol) of bisaminopropyl tetramethyldisiloxane, 8.1g (0.03mol) of n-octadecylamine as a monoamine were dissolved in 1,190g of N-methyl-2 - pyrrolidone, reacted at 60°C for 6 hours. A small amount of the obtained polyamic acid solution was fractionated, NMP was added, and the viscosity was measured as a solution having a solid content concentration of 10% by weight, and it was 65 mPa·s. Next, 2,400 g of N-methyl-2-pyrrolidone was added to the obtained polyamic acid solution, 396 g of pyridine and 409 g of acetic anhydride were added, and dehydration ring closure was performed at 110° C. for 4 hours. After the imidization reaction, the solvent in the system is replaced with a new N-methyl-2-pyrrolid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Boiling point | aaaaa | aaaaa |

| Solution viscosity | aaaaa | aaaaa |

| Solution viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com