Environment-friendly type corrosion resistant composition for normal temperature descaling of metal materials

A metal material and environment-friendly technology, applied in the field of metal surface treatment, can solve the problems of high cost, low efficiency and unenvironmental protection of rust removal methods, and achieve the effect of excellent adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

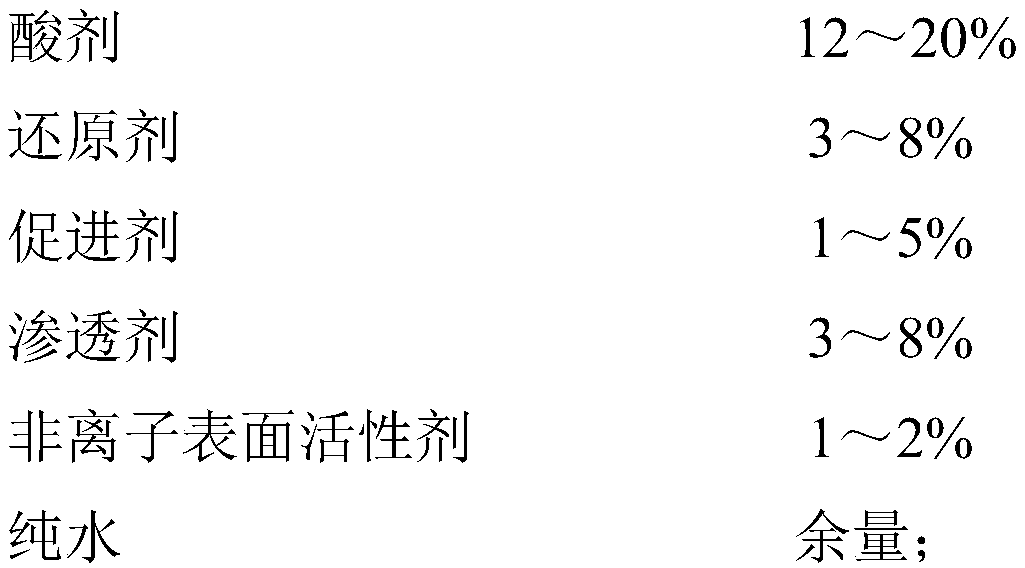

[0037] An environment-friendly corrosion-resistant composition for derusting metal materials at room temperature, comprising the following components and mass fractions:

[0038]

[0039] Wherein, the acid agent is an unsaturated organic acid and its compound, and the penetrant includes the following components and molar ratio:

[0040] Dipropylene glycol 2

[0041] Diethylene glycol ether 2

[0042] Diethylene glycol butyl ether 3,

[0043] The acid agent is mixed with sorbic acid, potassium sorbate and sodium sorbate in a molar ratio of 1:1:1.

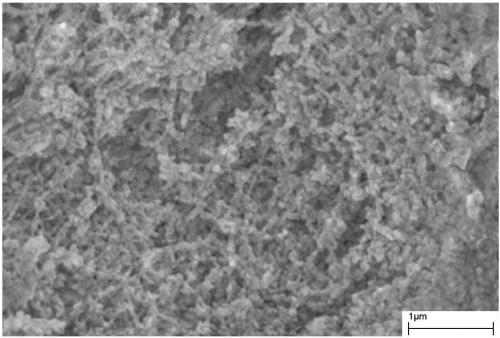

[0044] Such as figure 1 As shown, when applying this embodiment to remove oil stains and rust on the metal surface, a double protective film is formed on the surface. The specific reaction process is as follows:

[0045]When the metal is soaked in the treatment solution, the C5-7 isomeric alcohol polyoxyethylene ether and other substances in the treatment solution first react to emulsify the oil and dust on the surface of the ...

Embodiment 2

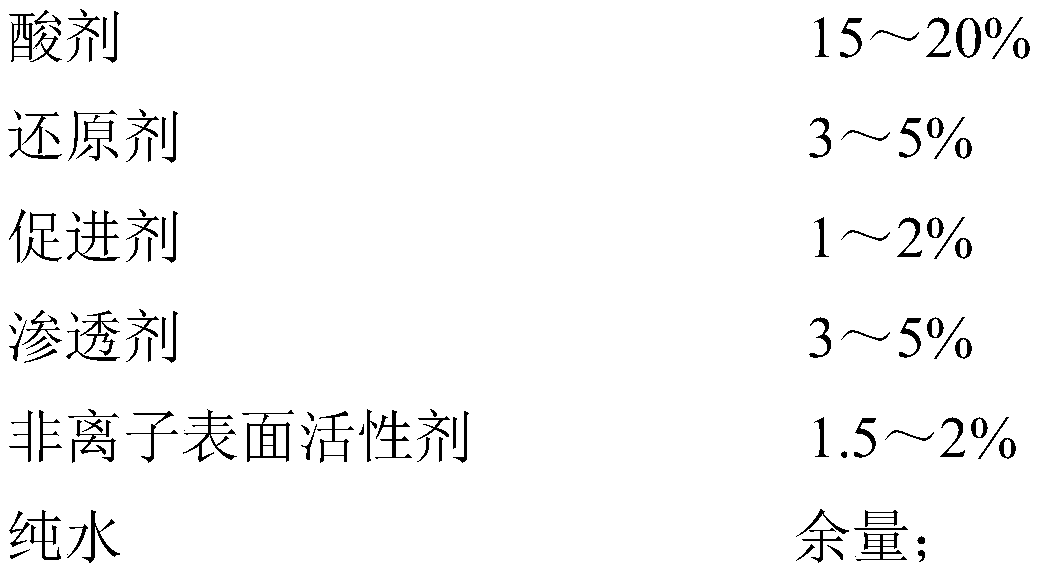

[0048] An environment-friendly corrosion-resistant composition for derusting metal materials at room temperature, comprising the following components and mass fractions:

[0049]

[0050]

[0051] Wherein, the acid agent is an unsaturated organic acid and its compound, and the penetrant includes the following components and molar ratio:

[0052] Dipropylene glycol 3

[0053] Diethylene glycol ether 3

[0054] Diethylene glycol butyl ether 4,

[0055] The acid agent is mixed with sorbic acid, potassium sorbate and sodium sorbate in a molar ratio of 1:1:1.

[0056] When this embodiment is applied to remove oil stains and rust on the metal surface, a double protective film is formed on the surface. At this time, the penetrant reacts with dipropylene glycol: diethylene glycol ethyl ether: diethylene glycol butyl ether in a molar ratio of 3:3:4, and the composite cross-linking points provided by dipropylene glycol reach the optimum content, forming a multilayer The qualit...

Embodiment 3

[0058] An environment-friendly corrosion-resistant composition for derusting metal materials at room temperature, comprising the following components and mass fractions:

[0059]

[0060] Wherein, the acid agent is an unsaturated organic acid and its compound, and the penetrant includes the following components and molar ratio:

[0061] Dipropylene glycol 4

[0062] Diethylene glycol ether 4

[0063] Diethylene glycol butyl ether 5,

[0064] The acid agent is mixed with sorbic acid, potassium sorbate and sodium sorbate in a molar ratio of 1:1:1.

[0065] When this embodiment is applied to remove oil stains and rust on the metal surface, a double protective film is formed on the surface. At this time, the penetrant reacts with dipropylene glycol: diethylene glycol ethyl ether: diethylene glycol butyl ether in a molar ratio of 4:4:5, and the content of composite crosslinking points provided by dipropylene glycol is within the allowable range, forming multiple The layered ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com