Automobile clutch diaphragm special-purpose water-based milling liquid and production method

A technology for clutches and grinding fluids, applied in lubricating compositions and the petroleum industry, etc., can solve problems such as short service life, burns on workpiece surfaces, poor lubricating performance and cooling performance, improve cooling effect, ensure surface quality, improve The effect of cooling performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Raw materials and weight percentages are as follows: phytic acid 1.8-2.2%, sodium benzoate 5-7%, alcohol amine 7-9%, sodium carbonate 3.5-4.5%, sodium thiosulfate 0.8-1.2%, polyethylene glycol 11-13 %, 2.5-3.5% triethanolamine oleate, 1.8-2.2% sodium dodecylbenzene sulfonate, 1.8-2.2% defoamer, 0.4-0.6% isothiazolinone, and 58-61% deionized water.

[0042] Each raw material can be selected within the weight range, so that the weight sum is 100%.

[0043] The production method is as follows:

[0044] a. First add the calculated amount of deionized water, phytic acid, sodium benzoate, and triethanolamine into the reaction kettle in turn, start the stirrer, and stir for 1 hour at normal temperature with a rotating speed of 200 rpm;

[0045] b. Then add the calculated amount of sodium carbonate, sodium thiosulfate, polyethylene glycol, triethanolamine oleate, sodium dodecylbenzenesulfonate, defoamer, and isothiazolinone into the reaction kettle in sequence, and heat To 50...

Embodiment 2

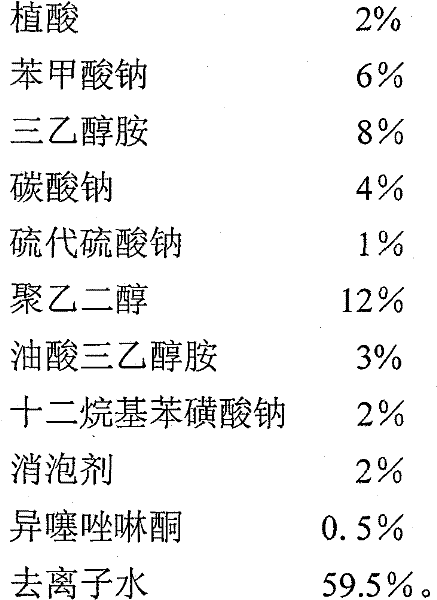

[0049] The production method is the same as in Example 1, except that the raw materials and weight percentages are as follows: 2% phytic acid, 6% sodium benzoate, 8% triethanolamine, 4% sodium carbonate, 1% sodium thiosulfate, 12% polyethylene glycol, oleic acid Triethanolamine 3%, sodium dodecylbenzene sulfonate 2%, defoamer 2%, isothiazolinone 0.5%, deionized water 59.5%.

[0050] Product Appearance: Viscous, slightly purple, transparent liquid.

[0051] The products of embodiment 1 and embodiment 2 of the present invention are prepared working liquid according to 5-8% when used, put into the grinding liquid tank of the machine tool, and adopt the pumping circulation spraying mode to carry out the grinding process. Applied to the grinding process of automobile clutch diaphragm, it can minimize the grinding temperature and grinding force, improve the grinding process efficiency, the grinding accuracy and surface quality of the workpiece, and prolong the service life of the gr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com