Chromium/diamond composite deposite and preparation method thereof

A composite coating and diamond technology, applied in coatings, electrolytic coatings, etc., can solve the problems of difficult diamond deposition and low current efficiency, and achieve the effects of high volume concentration, extended range, and improved shear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

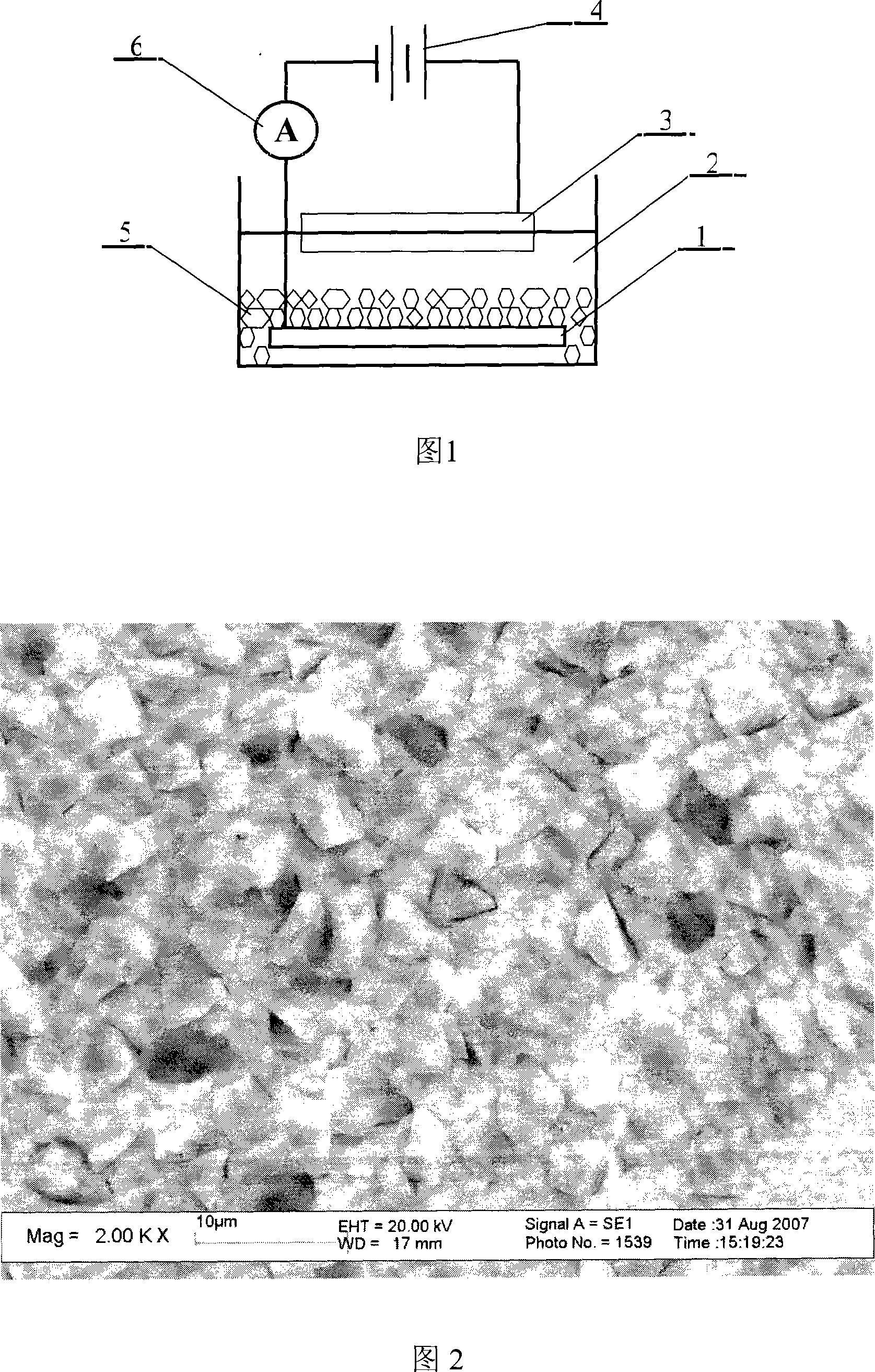

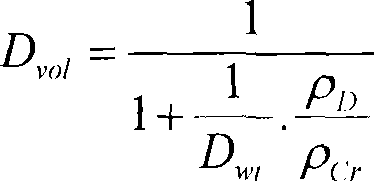

Method used

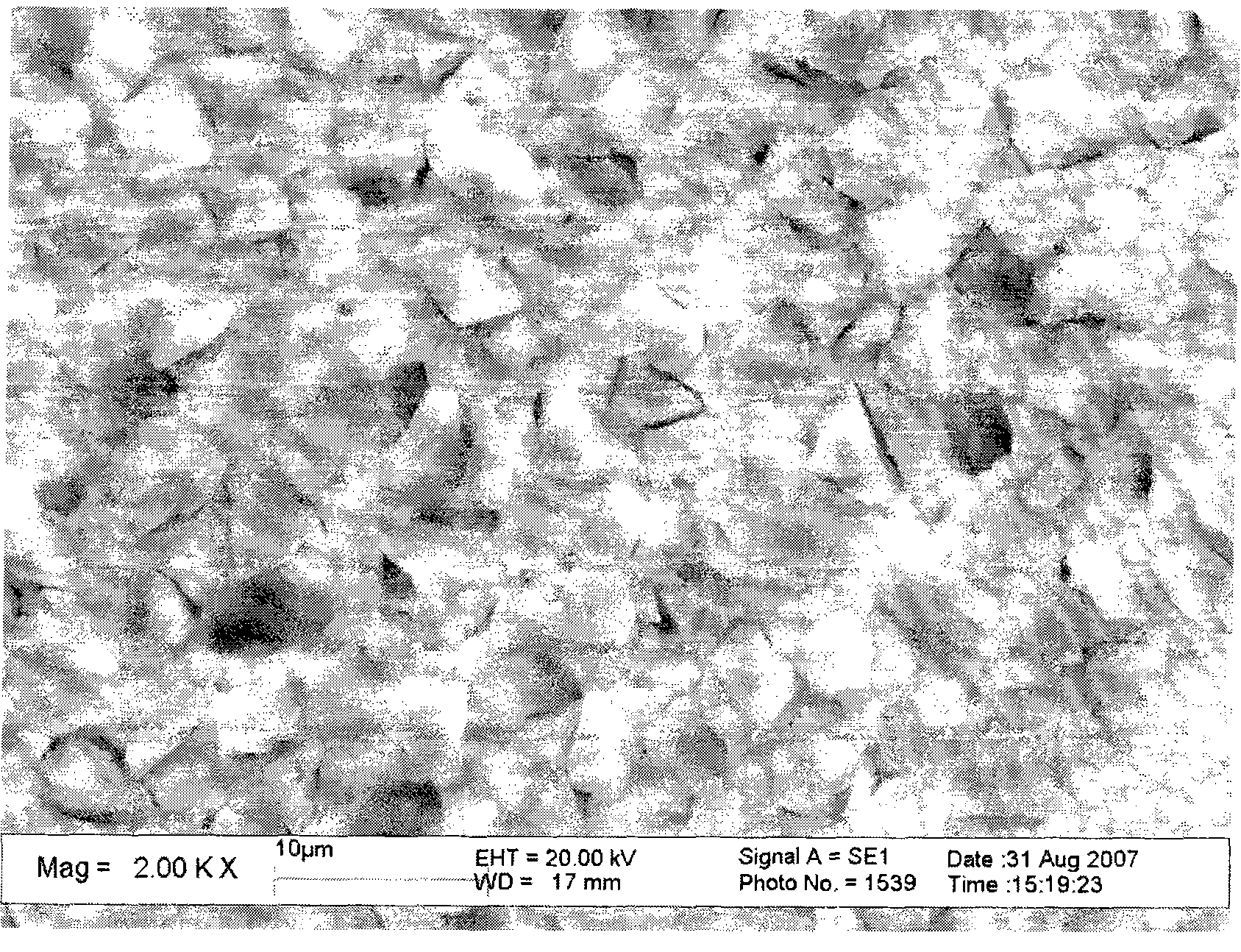

Image

Examples

Embodiment 1

[0031] (1) Take CrCl 3 ·6H 2 O 63.6g, HCOOK 48g, NH 4 Cl 33.6 g, KCl 45.6 g, H 3 BO 3 24 grams, NH 4 6 grams of Br, 0.6ml of additives; the above-mentioned components are dissolved in distilled water in order, and the next component is added after each component has been dissolved to form a 600ml trivalent chromium electroplating solution. The chromium electroplating solution is divided into the bottom plating tank, the upper sand plating tank and the reinforcement plating tank, and each electroplating tank is 200ml trivalent chromium plating solution; Boil in a fume hood for 45 minutes, rinse with distilled water until neutral, take 10 g and put it into the upper sand plating tank filled with trivalent chromium plating solution, and soak for 24 hours. The above-mentioned additive is a mixed solution of 5% OP emulsifier aqueous solution and 10% glycerol aqueous solution at a volume ratio of 1:1.

[0032](2) Use a copper sheet of Φ=20mm as the workpiece, protect the non-...

Embodiment 2

[0040] (1) Take CrCl 3 ·6H 2 O 108g, HCOOK 90g, NH 4 Cl 58.5g, KCl 81g, H 3 BO 3 45 g, NH 4 Br10.8 gram, additive 1.33ml; Dissolve above-mentioned components in distilled water in order, just add next kind of component after each component dissolves, be made into 900ml trivalent chromium electroplating solution, make the trivalent chromium electroplating solution that makes The chromium electroplating solution is divided into the bottom plating tank, the sand plating tank and the reinforcing plating tank, and each electroplating tank is 300ml trivalent chromium plating solution; Boil in a fume hood for 30 minutes, rinse with distilled water until neutral, take 10g and put it into the upper sand plating tank, soak for 20 hours. The above additive is a mixed solution of 6% OP emulsifier aqueous solution and 8% glycerol aqueous solution at a volume ratio of 0.4:1.

[0041] (2) Use Φ=20mm stainless steel as the workpiece, protect the non-electroplated surface (back) with ins...

Embodiment 3

[0049] (1) Take CrCl 3 ·6H 2 O 81g, HCOOK 54g, NH 4 Cl 41.4g, KCl 54g, H 3 BO 3 27 grams, NH 4 Br7.2 gram, additive 0.45ml; Above-mentioned component is dissolved in distilled water in order, and just adds next kind of component after each component dissolves, is made into 900ml trivalent chromium electroplating solution, and prepared trivalent chromium electroplating solution The chromium electroplating solution is divided into the bottom plating tank, the sand plating tank and the reinforcement plating tank, and each electroplating tank is 300ml trivalent chromium plating solution; Boil in a fume hood for 60 minutes, rinse with distilled water until neutral, take 12g and put it into the upper sand plating tank, soak for 30 hours. The above-mentioned additive is a mixed solution of 4% OP emulsifier by volume fraction and 12% glycerol aqueous solution with a volume ratio of 2:1.

[0050] (2) Use Φ = 20mm hard alloy as the workpiece, protect the non-electroplated surface...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com