Water-based single-component paint and multilayer film forming method

A single-component coating and single-based technology, which is applied in coatings, polyurea/polyurethane coatings, thin material treatment, etc., can solve the problem of reducing the concentration of adhesion on the surface of the coating film, reducing the compatibility of compounds and base resins, and damaging Appearance and other problems, to achieve excellent surface smoothness of coating film, improved adhesion of recoating, excellent hardness and acid resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

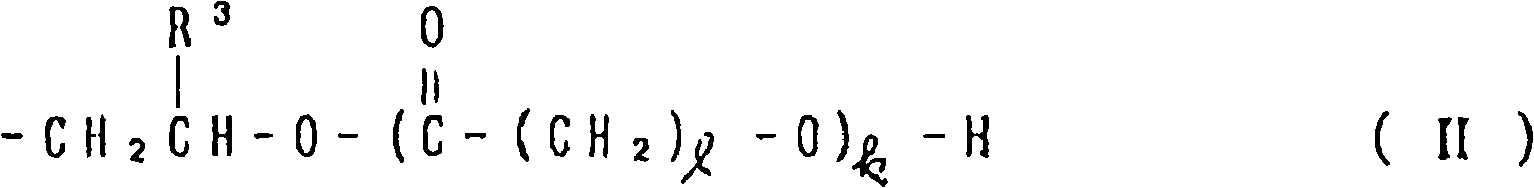

Method used

Image

Examples

Embodiment 1

[0175] In a 4-neck flask equipped with heater equipment, a stirrer, a thermometer and a reflux condenser, 30 parts of propylene glycol monopropyl ether were charged, and then the temperature inside the flask was raised to 145° C. under a stream of nitrogen. The nitrogen supply was stopped and, as a first stage, 15 parts of styrene, 10 parts of n-butyl acrylate, 18 parts of isobutyl methacrylate, 13 parts of 4-hydroxybutyl acrylate, 12 1 part PLACCEL FA-2, 7 parts 2-hydroxyethyl methacrylate and 3.0 parts di-tert-butyl peroxide. The reaction system was kept at the same temperature for another 30 min. Then, as the second stage, 6 parts of isobutyl methacrylate, 6 parts of 4-hydroxybutyl acrylate, 6 parts of PLACCEL FA-2, 3 parts of 2-hydroxyethyl methacrylate, 4 parts part of acrylic acid and 1.0 part of di-tert-butyl peroxide, and then aged at the same temperature for 1 h. Then, the solvent was distilled off under reduced pressure until the solids concentration rose to at lea...

Embodiment 2~15

[0177] Using the starting materials shown in Table 1, acrylic resins (A-2) to (A-15) were obtained in a similar manner to Production Example 1.

[0178] Table 1 shows the composition of the starting materials, the solid content and properties of the acrylic resins (A-1) to (A-15).

[0179]

[0180] Preparation of blocked polyisocyanate compound (B)

Embodiment 16

[0182] Put 250 parts of SUMIDUR N3300 into a 4-neck flask equipped with stirrer, heating device, cooling device and pressure reducer (注1) And 125 parts of methyl ethyl ketone, and heated to 30 ° C. Then, 126 parts of 3,5-dimethylpyrazole were gradually added within 2 hours while stirring, and the reaction mixture was reacted at 30°C under stirring until no free isocyanate groups were detected with an infrared spectrophotometer. After the end of the reaction, a solution of a blocked polyisocyanate compound (B-1) having a solid content of 70% was obtained. The resulting blocked polyisocyanate compound (B-1) had an SP measurement of 9.33, an NCO content of 14.4% and a number average molecular weight of 1,000. In the present specification, "NCO content" refers to the NCO group amount (%) per 100 parts by mass of the solid content of the resin.

[0183] (Note 1) SUMIDUR N3300: trade name, Sumika Bayer Urethane Co., Ltd., hexamethylene diisocyanate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com