Leaching method for alloy material obtained from magnetic copper-nickel concentrate

A leaching, copper-nickel technology, applied in the direction of process efficiency improvement, etc., can solve the problem of high recovery rate of platinum group metals, achieve the effect of environmental friendliness, simple and efficient method, and solve environmental pollution problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

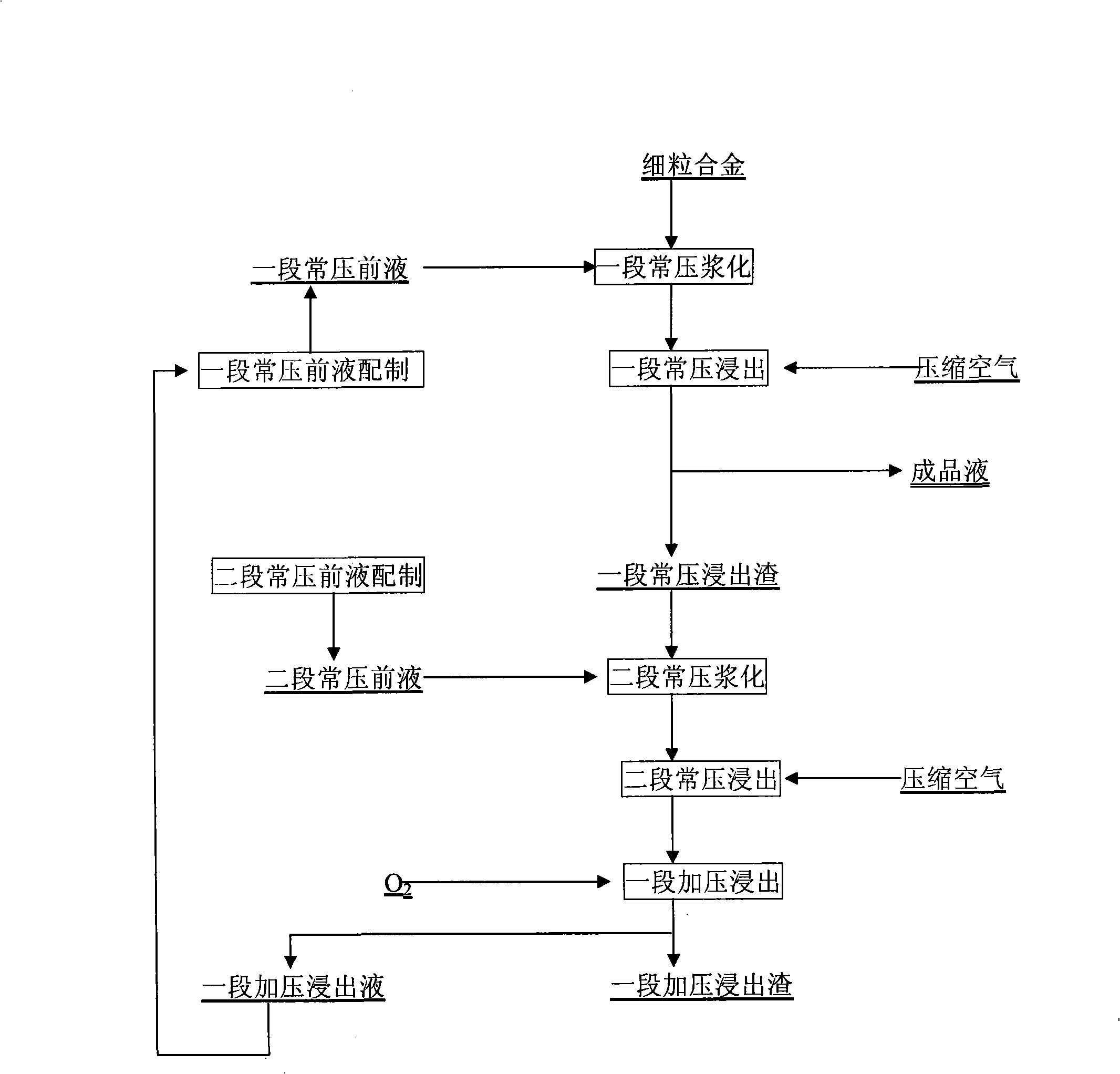

Method used

Image

Examples

Embodiment 1

[0015] The raw material composition of the alloy material for leaching magnetically separated copper-nickel concentrate is as follows:

[0016] The alloy material raw material composition (%, g / t) of the alloy material of table 1 magnetic separation copper-nickel concentrate

[0017] Ni(%) Co Cu Fe S SiO 2 Pt(g / t)PdAu

[0018] 59.4 1.23 4.48 13.35 14.17 2.42 51.0 26.0 32.0

[0019] Add the materials evenly to the batching slurry tank, and at the same time add the pressure leaching return liquid, water and sulfuric acid to the batching slurry tank, the liquid-solid ratio of the prepared slurry is 7m 3 / ton, the initial sulfuric acid concentration is 15g / l, pumped into a section of normal pressure oxidation tank, reacted at 80°C for 4 hours; carried out oxidation leaching under the condition of compressed air, after oxidation leaching, pumped into the thickener through the middle tank for Liquid-solid separation. The thickener overflows into the normal pressure leachate ...

Embodiment 2

[0023] The raw material composition of the alloy material for leaching magnetically separated copper-nickel concentrate is the same as Table 1

[0024] Add the material evenly to the batching slurry tank, and add the pressure leaching return liquid, water and sulfuric acid to the batching slurry tank at the same time, and the liquid-solid ratio of the prepared slurry is 7.5m 3 / ton, the initial sulfuric acid concentration is 14g / l, pumped into a normal pressure oxidation tank, and reacted at 80°C for 4 hours; oxidation leaching was carried out under the condition of compressed air, and then pumped into the thickener through the middle tank for oxidation leaching Liquid-solid separation. The thickener overflows into the normal pressure leachate storage tank.

[0025] The underflow of the thickener is pumped to a section of slag slurrying tank through the underflow pump, and water and sulfuric acid are added to the slurrying tank at the same time for batching. The liquid-solid...

Embodiment 3

[0028] The raw material composition of the alloy material for leaching magnetically separated copper-nickel concentrate is the same as Table 1

[0029] Put the material into the batching slurry tank evenly, and add the pressure leaching return liquid, water and sulfuric acid to the batching slurry tank at the same time, the liquid-solid ratio of the prepared slurry is 8:1m 3 / ton, the initial sulfuric acid concentration is 13g / l, pumped into a normal pressure oxidation tank, and reacted at 85°C for 4 hours; oxidation leaching was carried out under the condition of compressed air, after oxidation leaching, it was pumped into a thickener through the middle tank for Liquid-solid separation. The thickener overflows into the normal pressure leachate storage tank.

[0030] The underflow of the thickener is pumped to a section of slag slurrying tank through the underflow pump, and water and sulfuric acid are added to the slurrying tank at the same time for batching. The liquid-soli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com