Process and apparatus for treating sewage

A sewage treatment and process technology, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, flocculation/sedimentation water/sewage treatment, etc. Unable to meet the standards of reinjection or efflux, etc., to achieve high-efficiency nitrogen removal capacity, good treatment effect, and the effect of improving solid-liquid separation effect and separation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

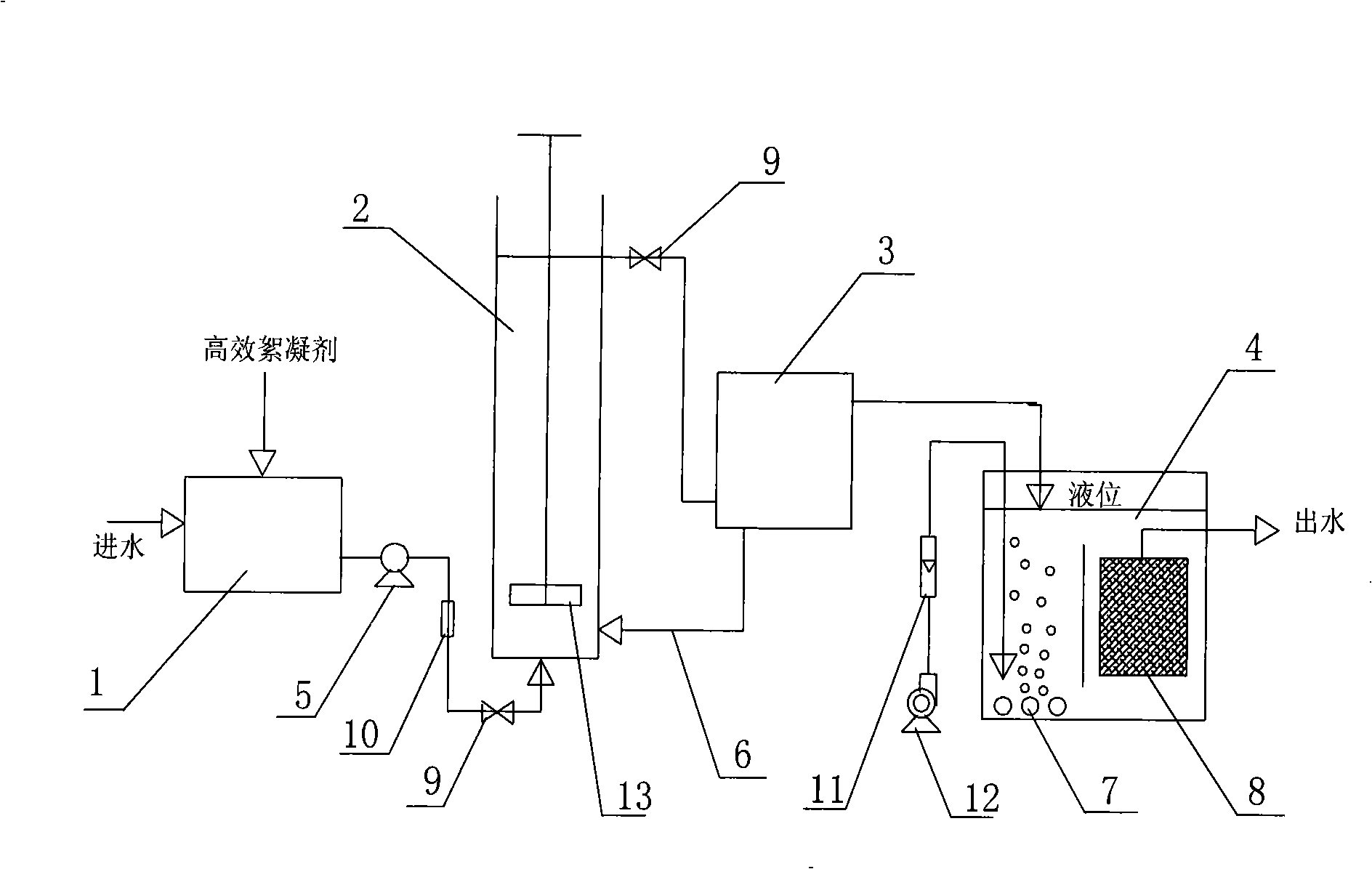

[0029] A sewage treatment process, the concrete steps are as follows:

[0030] 1) The oilfield produced water first enters the flocculation sedimentation tank 1, and a high-efficiency composite flocculant is added into the flocculation tank 1. After flocculation and sedimentation, most of the suspended particles and oil can be removed from the effluent;

[0031] 2) The supernatant in the flocculation sedimentation tank 1 enters the hydrolysis acidification tank 2 from the bottom of the hydrolysis acidification tank 2 through the peristaltic pump 5, and the hydrolysis acidification tank 2 is stirred with an electric mixer 13 to prevent the anaerobic sludge from settling; the hydrolysis acidification tank 2 It is set as an upper opening, exposed to the air, in an anoxic state, and inhibits the growth of methanogenic bacteria;

[0032] 3) The effluent from the hydrolytic acidification tank 2 enters the sedimentation tank 3 through the valve, and the sewage continues to undergo an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com