Cane sugar factory waste water zero discharge process

A zero-emission, cane sugar technology, applied in supplementary water supply, water shower coolers, preheating, etc., can solve the problems of large water consumption, high energy consumption, waste water pollution, etc., save production water, and achieve significant economic and social benefits. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

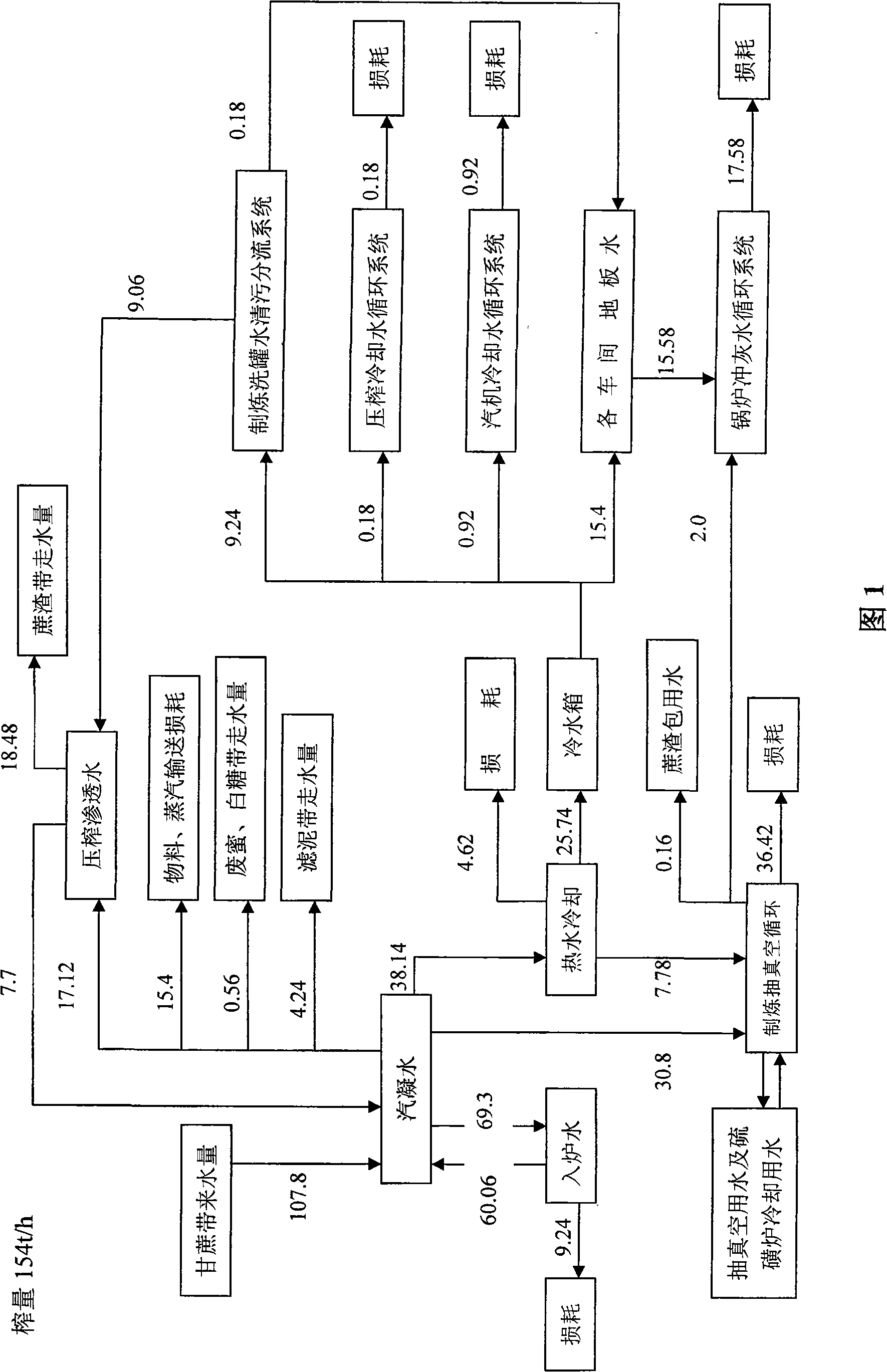

[0012] In the method for zero discharge of waste water from sugarcane sugar factories of the present invention, Fig. 1 shows that the production water is derived from the condensed water formed by the self-moisture of sugarcane. In this measurement, the daily squeezed sugarcane amount is 154 tons / hour, and the average water content of sugarcane is 70 % of the cases, the condensed water flow rate is about 107.8t / h, and these waters can completely replace fresh water after treatment, meeting the production water requirements.

[0013] The water entering the boiler comes from condensate water, the flow rate is about 69.3t / h, the flow rate back to the condensate water is about 60.06t / h, and the intermediate loss is 9.24t / h. Nanxu Sugar Factory adopts new high-efficiency corrugated juice catcher technology to transform the evaporation I effect and II effect juice catcher, which reduces the sugar content of the condensate water, so that the sugar content of the I effect and II effect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com