Fe-Al intermetallic compound/AL2O3ceramic composite coating and method of producing the same

An intermetallic compound, ceramic composite technology, applied in the direction of metal material coating process, coating, anodizing, etc., can solve the problems of limited application scope, brittleness, and difficult processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

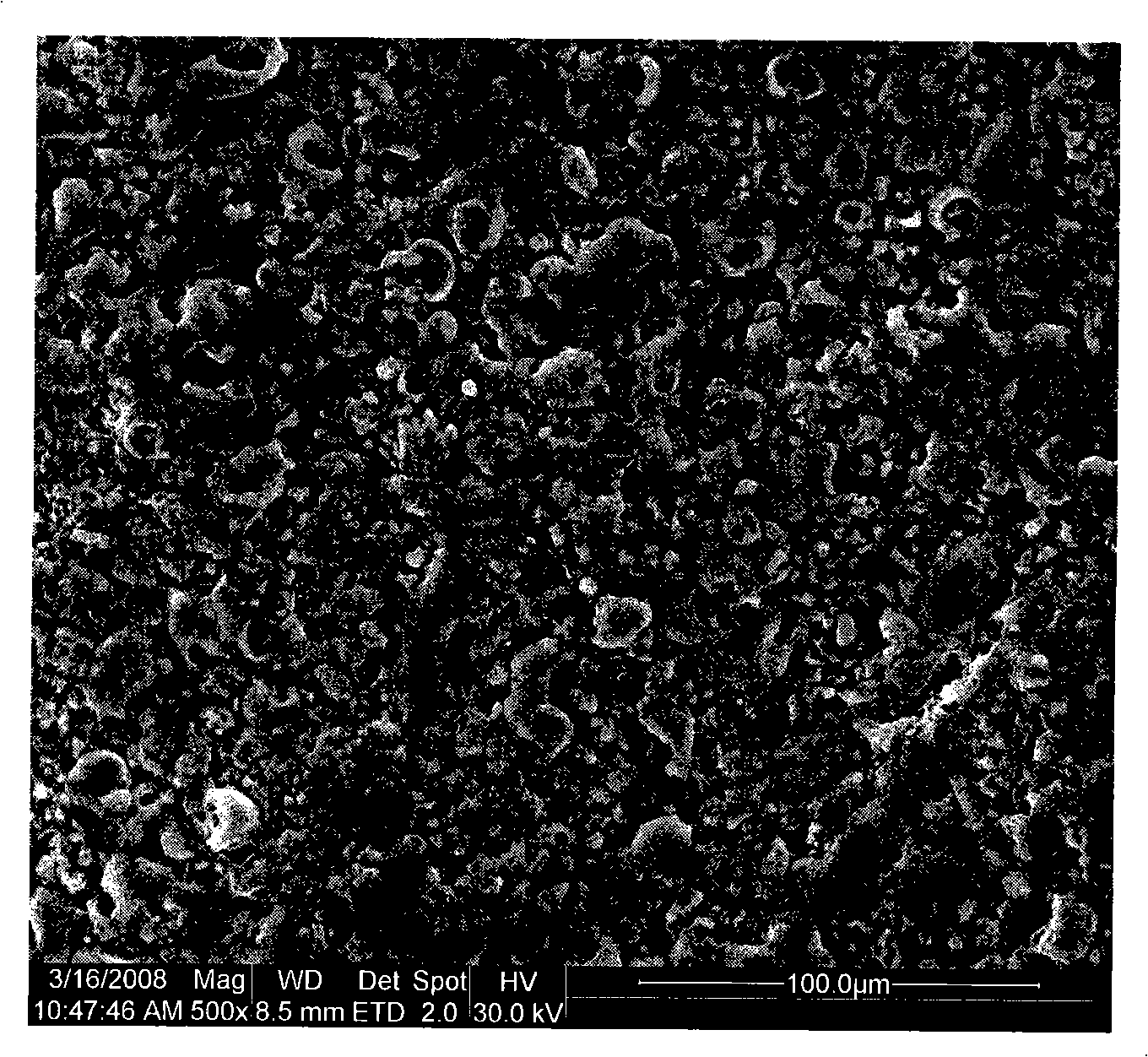

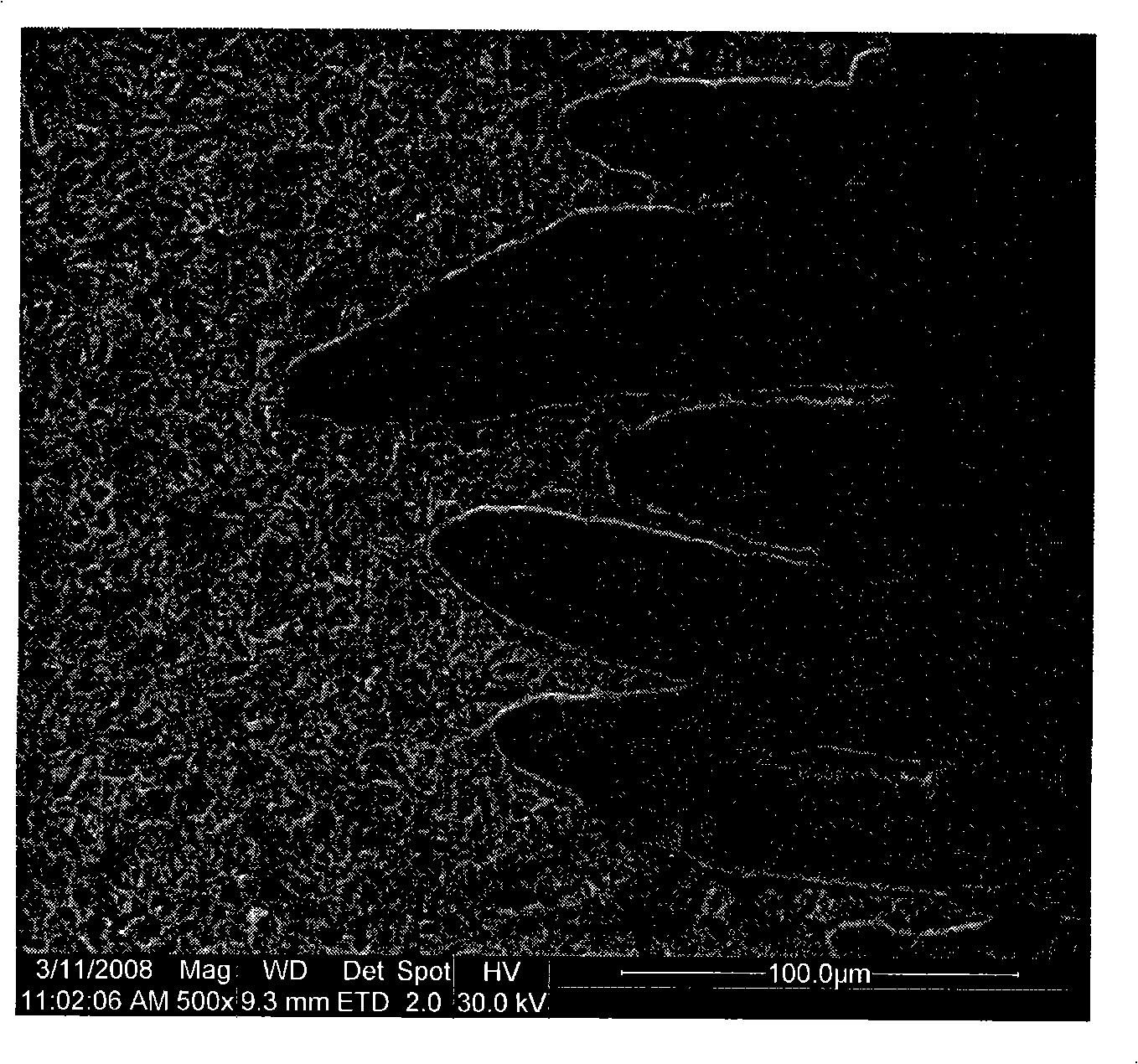

Image

Examples

Embodiment 1

[0024] Base material: 3Cr2W8V steel.

[0025] Flame spraying process parameters: the spraying distance is 100mm, the spraying angle is 80°~90°, the moving speed of the spray gun is 15cm / s, the thickness of each spraying is less than 0.10mm, and the coating thickness is 0.50mm.

[0026] Heat treatment process parameters: heating temperature: 600°C, holding time: 40min, cooling method: cooling with the furnace.

[0027] Micro-arc oxidation process parameters: current density at 10A / dm 2 , the solution temperature is 50°C, and the reaction time is 40min.

[0028] Composition of electrolyte: sodium hexametaphosphate 10g / L, sodium silicate 5g / L, sodium tungstate 5g / L, sodium carbonate 5g / L, sodium hydroxide 2g / L.

Embodiment 2

[0030] Base material: H13 steel.

[0031] Flame spraying process parameters: the spraying distance is 150mm, the spraying angle is 80°~90°, the moving speed of the spray gun is 15cm / s, the thickness of each spraying is less than 0.10mm, and the coating thickness is 1.0mm.

[0032] Heat treatment process parameters: heating temperature: 600°C, holding time: 60min, cooling method: cooling with the furnace.

[0033] Micro-arc oxidation process parameters: current density at 10A / dm 2 , the solution temperature is 50°C, and the reaction time is 60min.

[0034] Composition of electrolyte: sodium hexametaphosphate 15g / L, sodium silicate 10g / L, sodium tungstate 10g / L, sodium carbonate 10g / L, sodium hydroxide 5g / L.

Embodiment 3

[0036] Base material: 3Cr2W8V steel.

[0037] Flame spraying process parameters: the spraying distance is 180mm, the spraying angle is 80°~90°, the moving speed of the spray gun is 15cm / s, the thickness of each spraying is less than 0.10mm, and the coating thickness is 0.50mm.

[0038] Heat treatment process parameters: heating temperature: 540°C, holding time: 120min, cooling method: cooling with the furnace.

[0039] Micro-arc oxidation process parameters: current density at 15A / dm 2 , the solution temperature is 30°C, and the reaction time is 60min.

[0040] Composition of electrolyte: sodium hexametaphosphate 12g / L, sodium silicate 8g / L, sodium tungstate 8g / L, sodium carbonate 8g / L, sodium hydroxide 5g / L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com