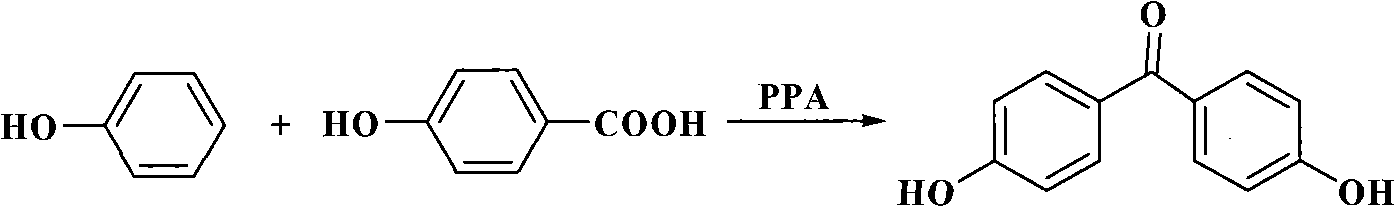

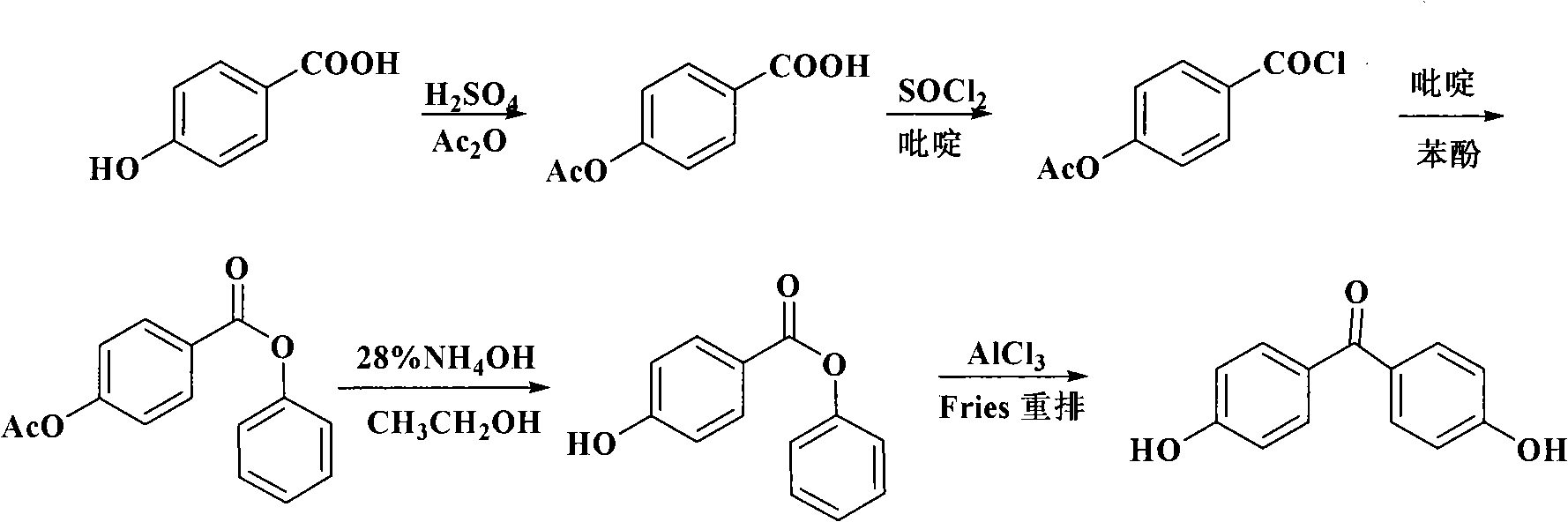

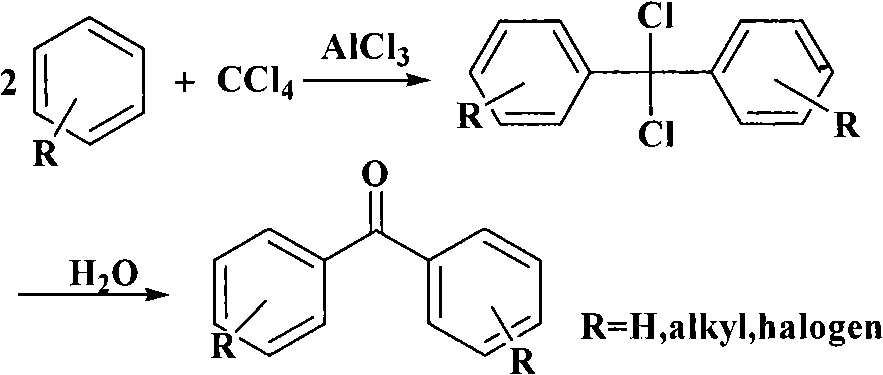

Process for synthesizing 4,4'-dihydroxy diphenylketone

A technology of dihydroxybenzophenone and synthetic methods, applied in 4 fields, can solve problems such as environmental pollution, achieve the effects of reducing production costs, easy handling and storage, and realizing resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1: the preparation of solid superacid catalyst

[0031] FeCl 3 ·6H 2 O10g was dissolved in 100mL distilled water, and 25% (w / w) ammonia water was added to adjust the pH to 8 to obtain ferric hydroxide sol, which was filtered, and the filter cake was washed with distilled water to remove Cl - , dried, placed in 0.25mol / L H 2 SO 4 Solution (15mL / g) was impregnated, then filtered, dried, and roasted at 500°C to obtain the solid superacid catalyst (SO 4 2- / Fe 2 o 3 ).

Embodiment 2

[0033] Take commercially available Fe(NO 3 ) 3 9H 2 O10g was dissolved in 100mL distilled water, and urea was added to adjust the pH to 9 to obtain ferric hydroxide sol, which was filtered, and the filter cake was washed with distilled water to remove NO 3 -, dried, placed in 0.50mol / L (NH 4 ) 2 SO 4 Solution (15mL / g) was impregnated, then filtered, dried, and roasted at 550°C to obtain the solid superacid catalyst (SO 4 2- / Fe 2 o 3 ).

Embodiment 3

[0035] commercially available anhydrous AlCl 3 Dissolve 5 g in 50 mL of distilled water, add 25% (w / w) ammonia water to adjust the pH to 8, obtain aluminum hydroxide sol, filter, and wash the filter cake with distilled water to remove Cl - , dried, placed in 2.50mol / L H 2 SO 4 Solution (15mL / g) was impregnated, then filtered, dried, and roasted at 600°C to obtain the solid superacid catalyst (SO 4 2- / Al 2 o 3 ).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com