Method for preparing nano copper oxide anti-bacteria agent

A technology of nano-copper oxide and antibacterial agent, which is applied in the field of preparation of nano-copper oxide antibacterial agent, can solve the problems of low antibacterial performance, high energy consumption and long time of nano-copper oxide, and achieves low pollution, high purity and good antibacterial effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

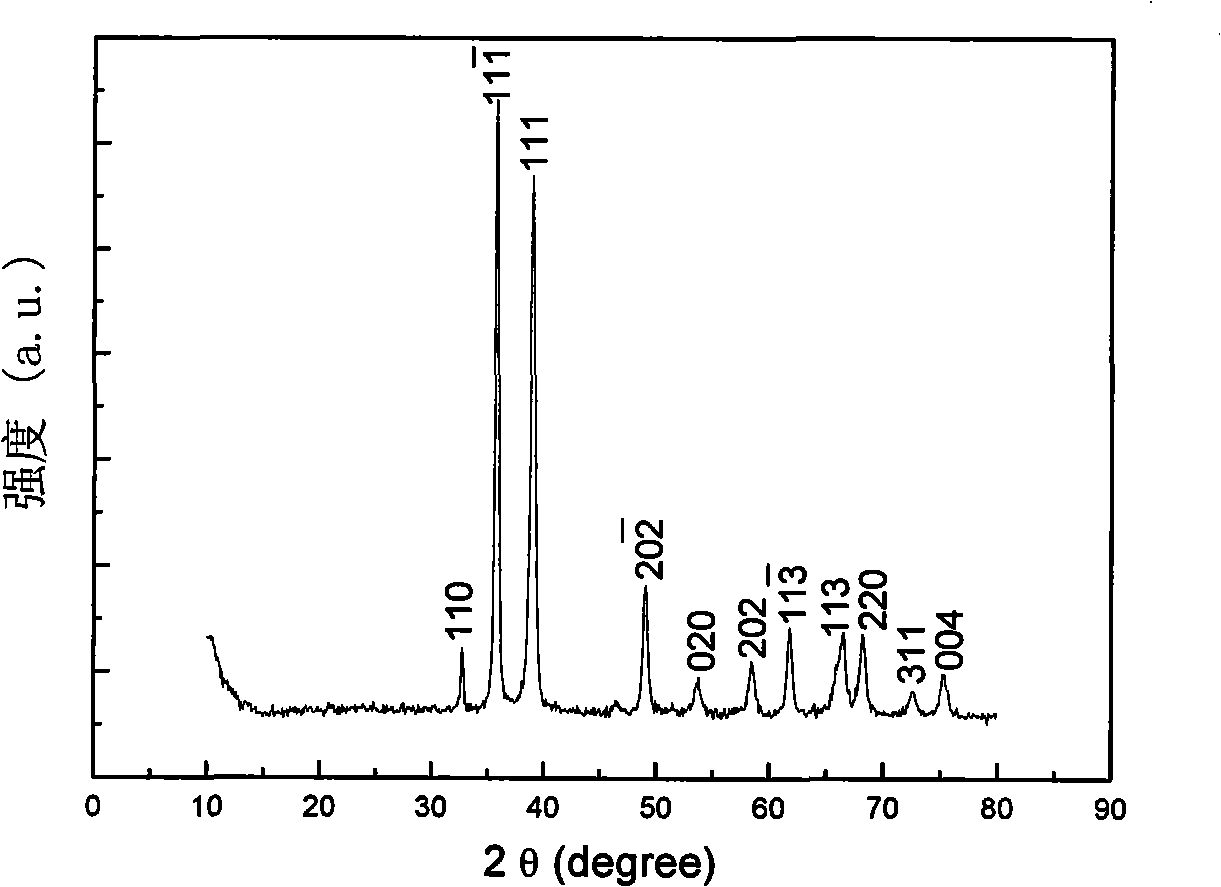

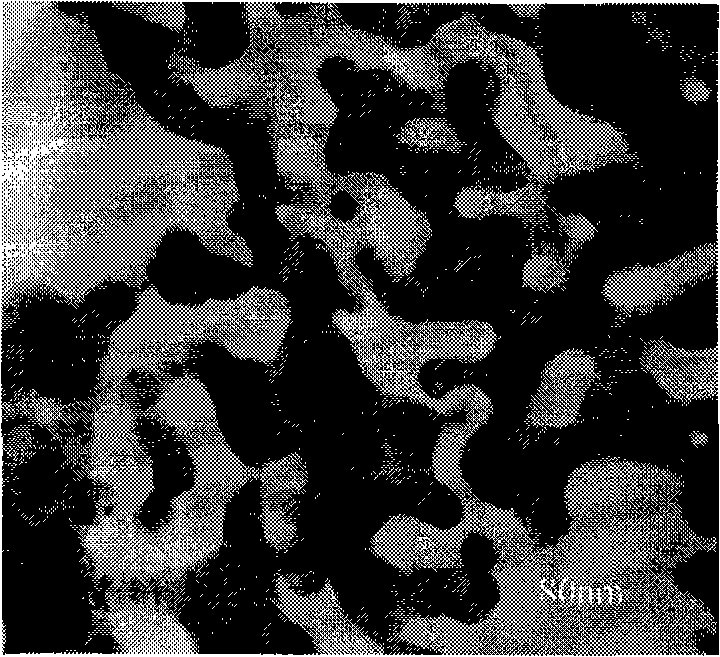

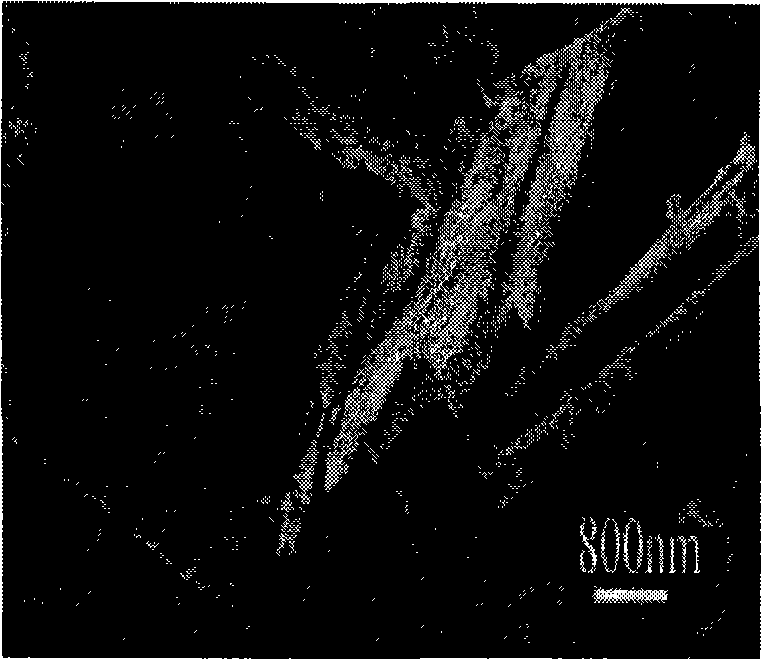

[0006] A preparation method of nanometer copper oxide antibacterial agent, is characterized in that, adopts microwave-assisted method, specifically comprises the following steps:

[0007] 1) Deionized aqueous solutions of copper nitrate and urea were prepared respectively, the concentration of the copper nitrate solution was 0.1M, and the concentration of the urea solution was 0.4-0.6M;

[0008] 2) Take an equal volume of the above-mentioned copper nitrate solution and urea solution in a three-necked flask, place the three-necked flask in a microwave oven, and under magnetic stirring, set the power to 300-900W and react at 50-100°C for 15-60 minutes to obtain green cloudy liquid;

[0009] 3) Centrifuge the turbid liquid obtained in step 2), wash the separated solid with deionized water and absolute ethanol for 1 to 4 times, and then place it in a constant temperature drying oven at 80°C for 2 hours to obtain Basic copper carbonate precursor;

[0010] 4) Put the basic copper ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com