Method for directly preparing nano-catalyst based on Pd for alcohol fuel battery

A nano-catalyst, fuel cell technology, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of low electrocatalytic activity, reduced battery performance, and methanol waste. and other problems, to achieve the effect of high activity, high recovery rate and strong methanol resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The preparation of embodiment 1, Pd / C (20wt.%) catalyst

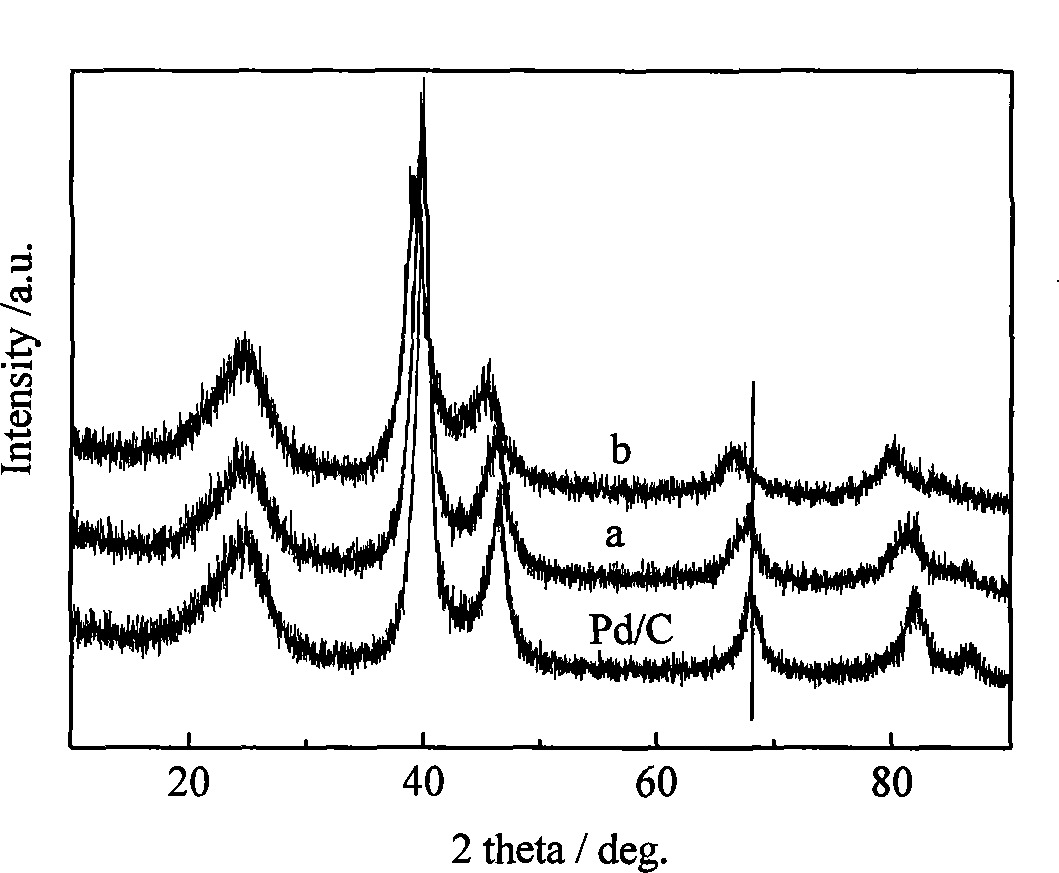

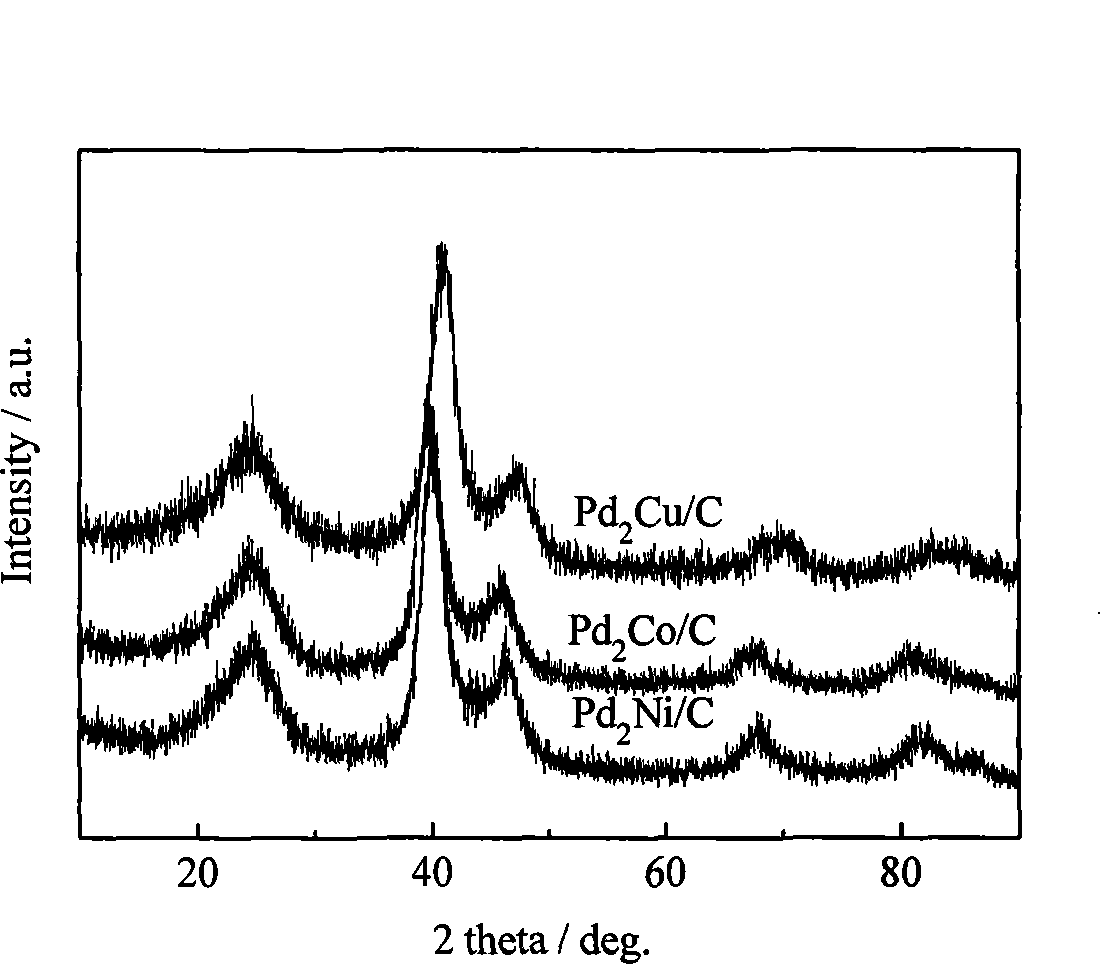

[0028] Weigh 80mg of dry activated carbon carrier XC-72R and 100mg of sodium citrate, add it into 50ml of ethylene glycol, stir for 4 hours with magnetic force to disperse evenly; weigh 57.6mg of Pd(acac) 2 , and added to the homogeneously dispersed carbon-containing slurry; the obtained slurry was reduced in a constant temperature oil bath at 198°C for 6h, then cooled to room temperature, washed with ultrapure water, filtered and placed in an oven at 75°C for 10h in vacuum to obtain a Pd / C catalyst . Its XRD pattern is attached figure 1 , based on the (220) crystal plane, calculated according to the Scherrer equation, the particle size of the Pd / C catalyst is about 6.0nm. The performance of its electrocatalytic oxidation of formic acid is shown in the appendix Figure 4 , the maximum current density is about 24.3mA cm -2 , it can be seen that Pd / C has a high activity for the electrocatalytic oxidation of for...

Embodiment 2

[0029] Example 2, Pd 3 Preparation of Pt / C (20wt.%) Catalyst

[0030] Weigh 80mg of dry activated carbon carrier XC-72R, add it into 50ml of ethylene glycol, stir for 4 hours with magnetic force to disperse evenly; weigh 35.7mg of Pd(acac) 2 and 15.8 mg platinum acetylacetonate Pt(acac) 2 , and added to the homogeneously dispersed carbon-containing slurry; the obtained slurry was reduced in a constant temperature oil bath at 175°C for 6h, then cooled to room temperature, washed with ultrapure water, filtered and placed in an oven at 75°C for 10h in vacuum to obtain Pd 3 Pt / C catalyst. Due to Pd(acac) 2 Compared with Pt(acac) 2 The decomposition temperature is low, so during the oil bath reduction process, Pd(acac) 2 Decompose and reduce first, the obtained Pd 3 The surface of Pt / C catalyst nanoparticles is rich in Pt. Its XRD pattern is attached figure 1 The middle curve a is based on the (220) crystal plane, calculated according to the Scherrer equation, Pd 3 The par...

Embodiment 3

[0031] Example 3, Pd3 Preparation of Pt / C (20wt.%) Catalyst

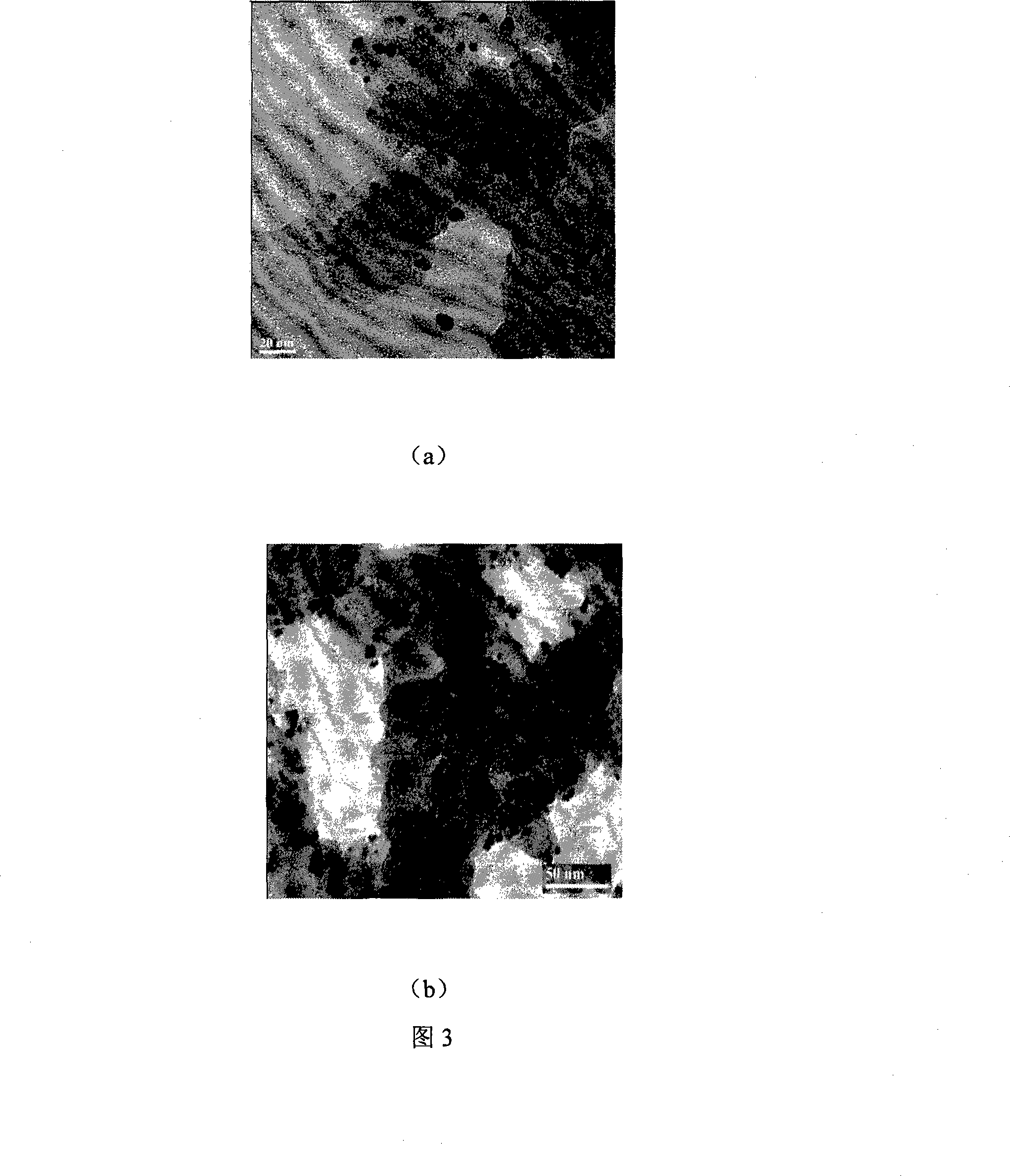

[0032] Weigh 80mg of dry activated carbon carrier XC-72R and 150mg of sodium citrate, add it into 50ml of ethylene glycol, stir for 4 hours with magnetic force to disperse evenly; weigh 35.7mg of Pd(acac) 2 and 15.8 mg Pt(acac) 2 , and added to the homogeneously dispersed carbon-containing slurry; the obtained slurry was reduced in a constant temperature oil bath at 175°C for 6h, then cooled to room temperature, washed with ultrapure water, filtered and placed in an oven at 75°C for 10h in vacuum to obtain Pd 3 Pt / C catalyst. Its XRD pattern is attached figure 1 The middle curve b, based on the (220) crystal plane, calculated according to the Scherrer equation, Pd 3 The particle size of the Pt / C catalyst is about 4.5nm; its TEM is shown in Figure 3(b), the particle size obtained by TEM is about 4.8±0.8nm, and the particle size of the catalyst obtained by XRD pattern and TEM is consistent. Due to Pd(acac) 2 Comp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com