Preparation of calcium type polyaluminium chloride purificant

A technology of polyaluminum chloride and water purifying agent, which is applied in the chemical industry, can solve the problems such as the inability to accurately calculate the dosage of the regulator, affect the quality and performance of the product, and affect the polymerization process, so as to improve the flocculation performance and stability, and is not easy to secondary The effect of pollution and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

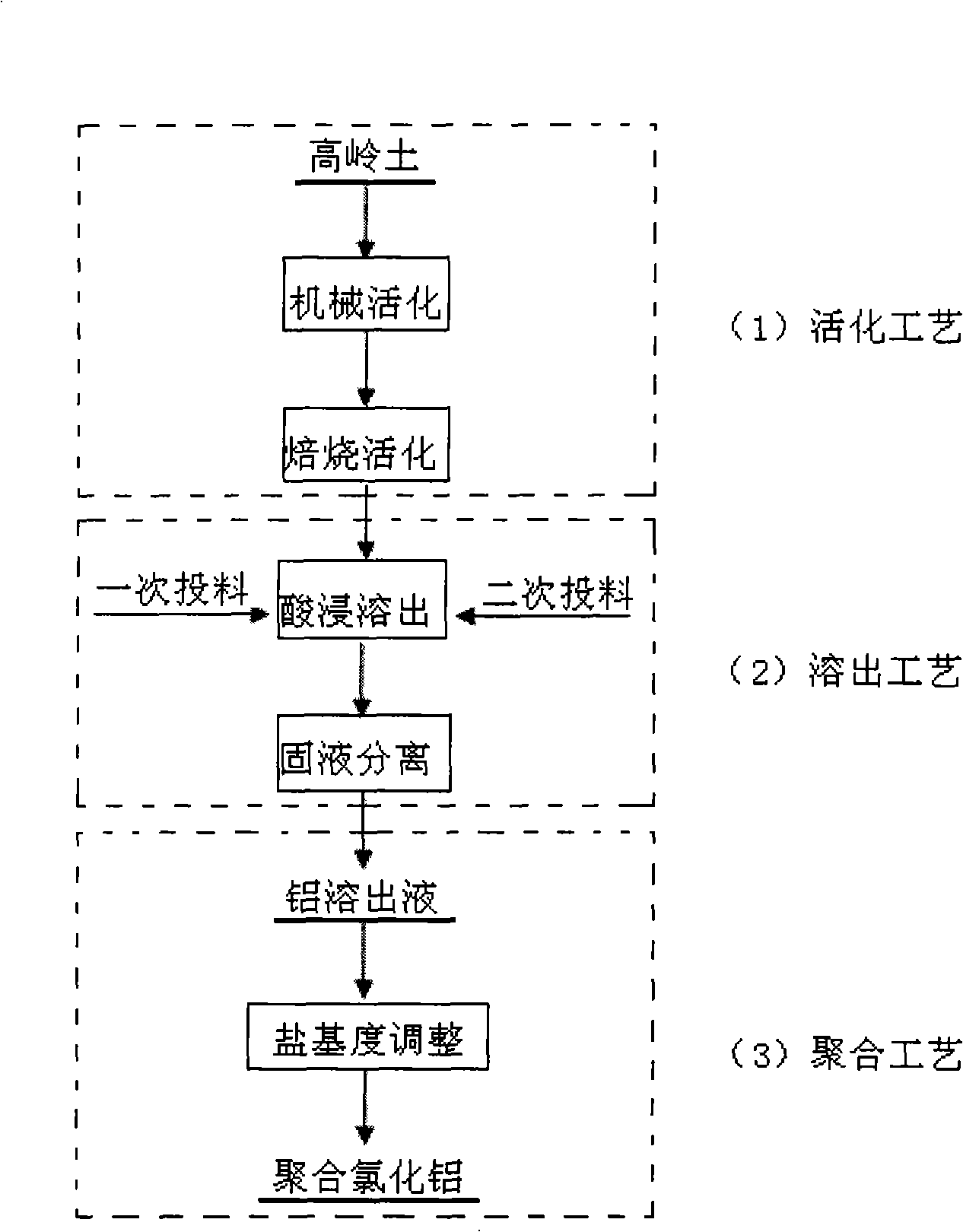

Method used

Image

Examples

Embodiment 1

[0036] The raw ore of kaolin was milled with a ball mill for 2 hours according to ore sample: zirconium ball: water (mass ratio) = 1:5:3, then stood for stratification, removed water, and dried in a constant temperature drying oven at 95°C. Weigh a certain amount of dried ore sample, raise it to 750°C in a muffle furnace, keep it warm for 2 hours, and then cool to obtain clinker. Weigh 45.885g of clinker, take 30.554g and put it into the reaction kettle, add 247.5mL of 15% hydrochloric acid according to the ratio of alumina to acid (1:5.57). Place the reaction kettle on a magnetic stirrer with a stirring speed of 1785r / min, raise the temperature to about 100°C and keep it warm for 2 hours, then add 15.331g (remaining clinker) clinker, and react for 1.5 hours. Stop stirring. Cool and filter, weigh the weight of the filtrate, and measure the alumina content and basicity to be 3.80% and 17.70% respectively. The eluate was placed on a magnetic stirrer with a stirring speed of 10...

Embodiment 2

[0038] In Example 1, the weighed clinker 45.885g was changed to 105.547g, 69.9824g was taken and put into the reaction kettle, and 420mL of 20% hydrochloric acid was added according to the alumina-acid ratio (1:5.64). Place the reaction kettle on a magnetic stirrer with a stirring speed of 1020r / min, raise the temperature to about 100°C and keep it warm for 2 hours, then add 35.5646g (residual clinker) clinker, and react for 1.5 hours. Stop stirring. Cool and filter, weigh the weight of the filtrate, and measure the alumina content and basicity to be 4.89% and 20.20% respectively. The eluate was placed on a magnetic stirrer with a stirring speed of 1275r / min. Weigh CaCO 3 , 56.640g was put into the eluate in batches, and the eluate was heated up at the same time. CaCO 3 After the dissolution is complete, keep warm to evaporate excess water. Afterwards, a brown liquid was obtained after cooling, and the alumina content and basicity of the product were measured to be 10.03%...

Embodiment 3

[0040]In Example 1, the weighed clinker was changed from 45.885g to 105.423g, 69.755g was put into the reaction kettle, and 610mL of 15% hydrochloric acid was added according to the alumina-acid ratio (1:6). Place the reaction kettle on a magnetic stirrer with a stirring speed of 1020r / min, raise the temperature to about 100°C and keep it warm for 2 hours, then add 35.670g (residual clinker) clinker, and react for 1.5 hours. Stop stirring. After cooling and filtering, the weight of the filtrate was weighed, and the alumina content and basicity were measured to be 5.29% and 12.04% respectively. The eluate was placed on a magnetic stirrer with a stirring speed of 2300r / min (fast). Weigh CaCO 3 , 65.864g was put into the eluate in batches, and the eluate was heated up at the same time. CaCO 3 After the dissolution is complete, keep warm to evaporate excess water. Afterwards, a pale yellow liquid was obtained after cooling, and the alumina content and basicity of the product ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com