Device for testing leadless solder welding spot crystal crack

A crystal crack, lead-free solder technology, used in optical testing flaws/defects, metal processing, etc., to ensure reliability, small size, and good reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

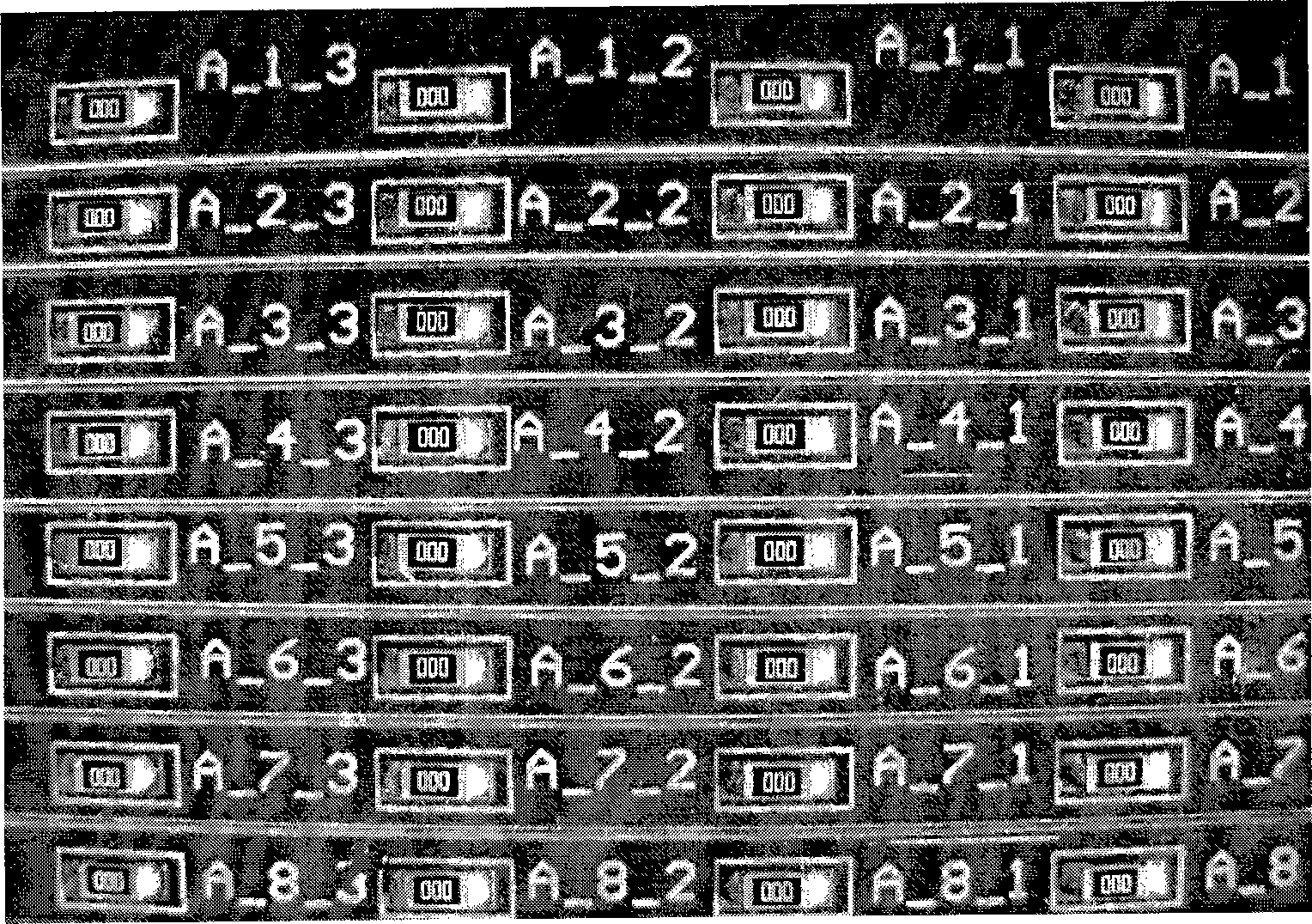

Image

Examples

Embodiment 1

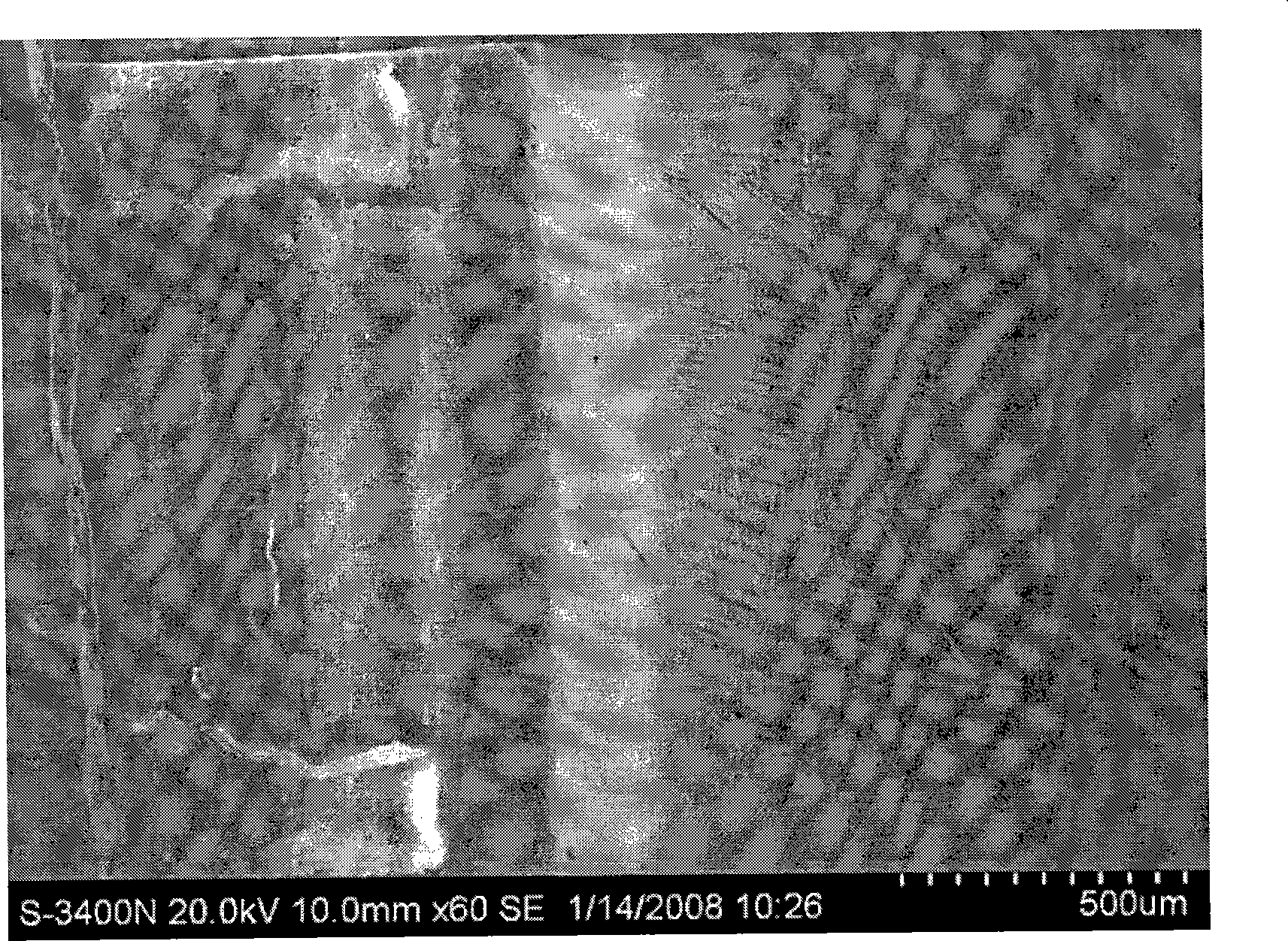

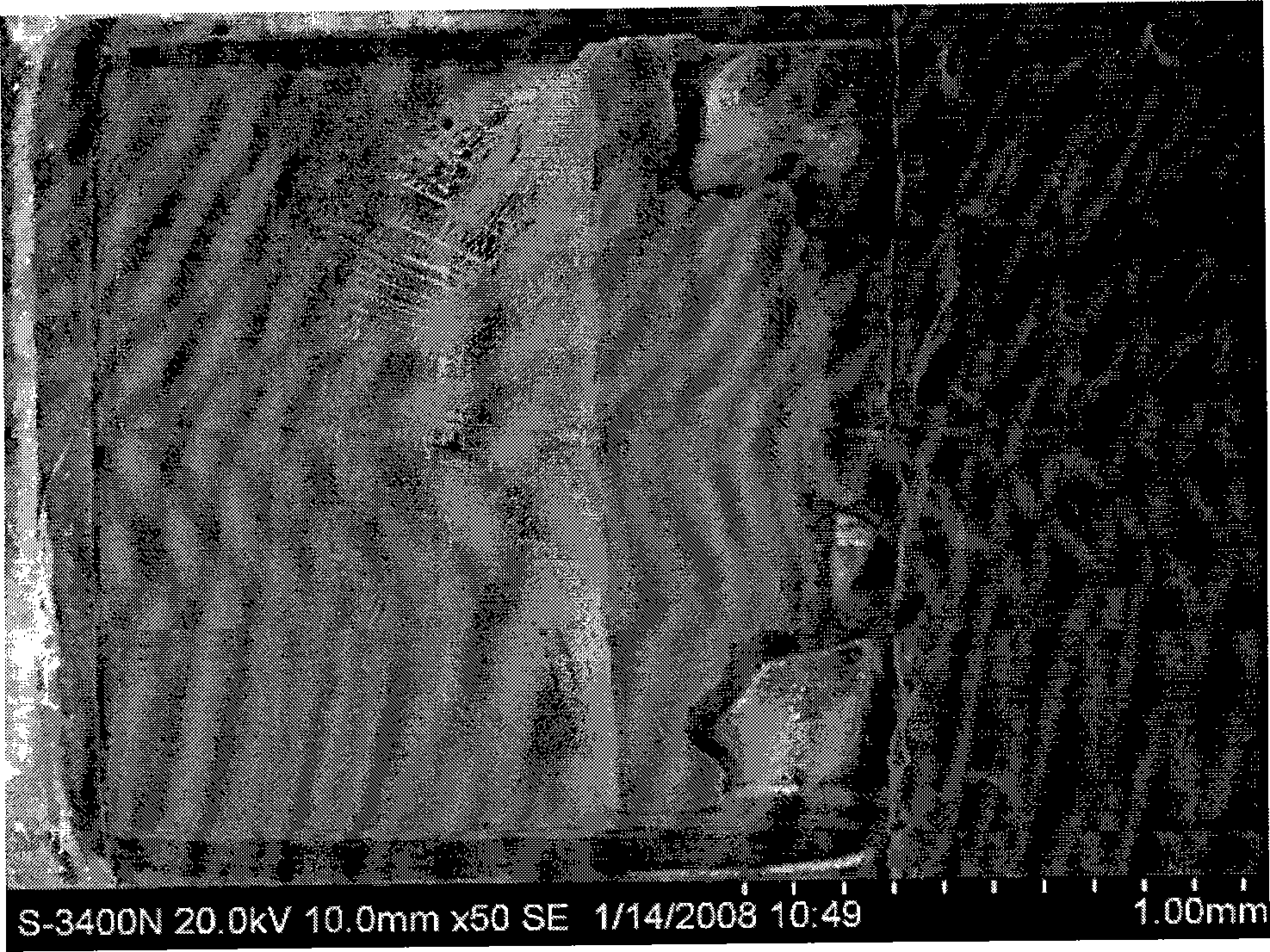

[0034] Embodiment 3: This embodiment uses lead-free solder Sn3.0Ag0.5CuP, and the flux is corrosive ZnCl 2 +NH 4 Cl+H 2 O solution, the brazing temperature is 260°C. The crystal crack test specimen is a cuboid with a volume of 20mm×12mm×3mm, the length of the middle groove is 16mm, the width is 4mm, and the depth is 2mm. After welding, it is naturally cooled in the air. After cooling, remove the residue on the surface of the solder joint to ensure the surface clean. Then magnify 10 times under a stereoscopic microscope to observe the crystallization cracks on the surface of the solder joints. The measured total length of the crack is half of the length of the brazing seam in the middle slot. Sn3.0Ag0.5CuP lead-free solder alloy has poor resistance to crystal cracking.

Embodiment 2

[0035] Embodiment 4: This embodiment uses lead-free solder Sn3.0Ag0.5CuCe, and the flux is corrosive ZnCl 2 +NH 4 Cl+H 2 O solution, the brazing temperature is 260°C. The crystal crack test specimen is a cuboid with a volume of 30mm×30mm×10mm, the length of the middle groove is 26mm, the width is 7mm, and the depth is 6mm. After welding, it is naturally cooled in the air. After cooling, remove the residue on the surface of the solder joint to ensure the surface clean. Then magnify 10 times under a stereoscopic microscope to observe the crystallization cracks on the surface of the solder joints. The measured total length of the crack is one-tenth of the length of the brazing seam in the middle slot. The ability of Sn3.0Ag0.5CuCe lead-free solder alloy to resist crystal cracking is average.

Embodiment 3

[0036] Embodiment 5: This embodiment uses lead-free solder Sn3.0Ag0.5CuGe, and the flux is corrosive ZnCl 2 +NH 4 Cl+H 2 O solution, the brazing temperature is 260°C. The crystal crack test specimen is a cuboid with a volume of 30mm×30mm×20mm, the length of the middle groove is 20mm, the width is 7mm, and the depth is 3mm. After welding, it is naturally cooled in the air. After cooling, remove the residue on the surface of the solder joint to ensure the surface clean. Then magnify 10 times under a stereoscopic microscope to observe the crystallization cracks on the surface of the solder joints. The measured total length of the crack is half of the length of the brazing seam in the middle slot. Sn3.0Ag0.5CuGe lead-free solder alloy has poor resistance to crystallization cracks.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com